Robotics in Warehousing & Logistics

The logistics sector is undergoing a paradigm shift towards intelligent automation. From autonomous mobile robots streamlining order fulfillment to self-driving forklifts managing heavy inventory, robotics solutions are addressing critical labor shortages and redefining supply chain efficiency.

Why Robotics Matters Here

Labor Shortage Mitigation

Warehouses face chronic staffing challenges. Robots fill the gap by handling repetitive transport tasks 24/7 without burnout or injury risks.

Order Fulfillment Speed

Modern commerce demands next-day delivery. AMRs reduce travel time for pickers, significantly increasing picks per hour.

Inventory Accuracy

Manual stocktaking is prone to error. Automated scanning robots provide real-time, 99.9% accurate inventory visibility.

Space Optimization

Robotic systems can operate in narrower aisles and higher vertical spaces than traditional forklifts, maximizing facility density.

Workplace Safety

Heavy lifting and high-traffic forklift zones are major hazards. Automation takes over dangerous tasks, reducing accidents and liability.

Scalability

Seasonal peaks require flexibility. Robotic fleets can be scaled up or down rapidly compared to hiring and training temporary staff.

Applications in Warehousing & Logistics

Warehouse Material Transport

Learn how warehouse material transport transforms warehousing & logistics.

Explore Application →Inventory Management & Stocktaking

Learn how inventory management & stocktaking transforms warehousing & logistics.

Explore Application →Assembly Line Transport

Learn how assembly line transport transforms warehousing & logistics.

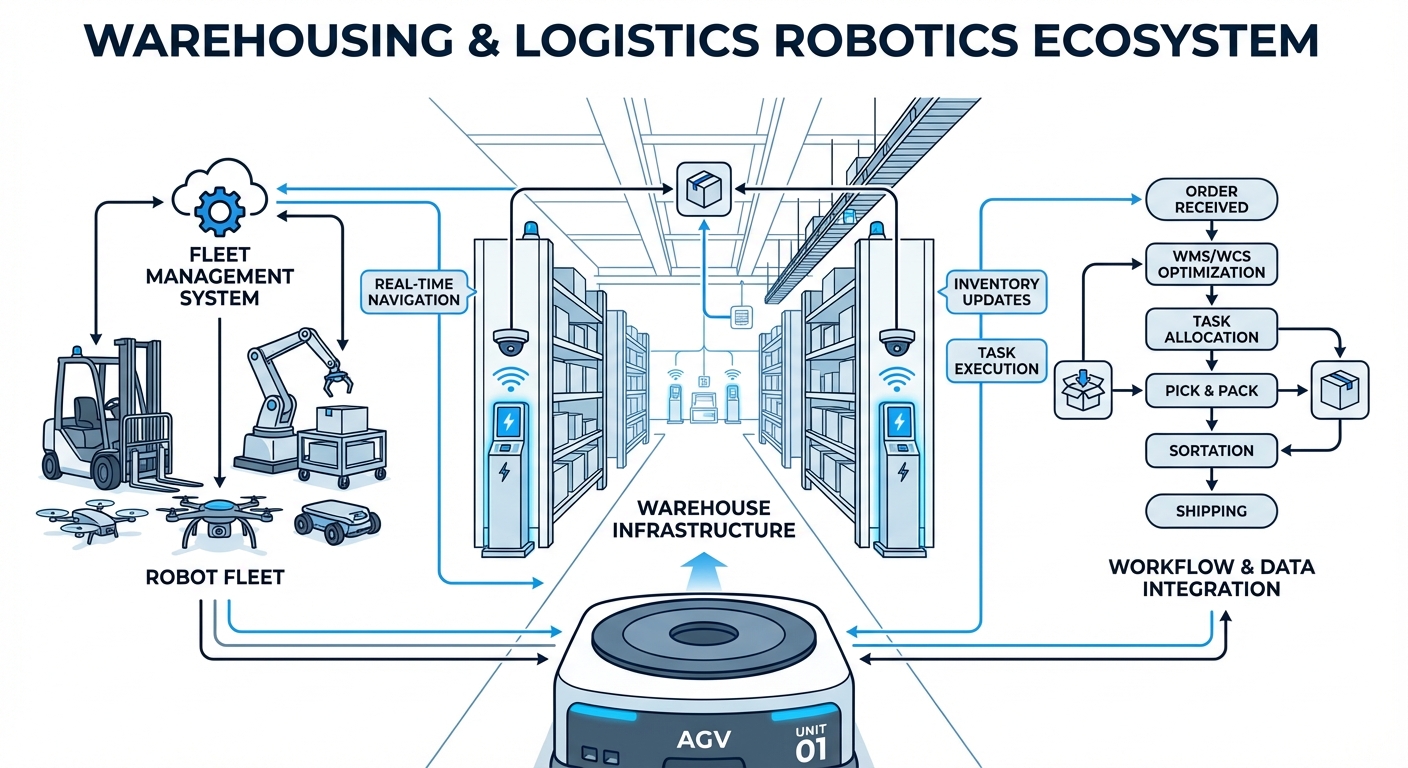

Explore Application →How to Deploy

1. Workflow Assessment: We analyze your current material flow, identifying bottlenecks in dock-to-stock, picking, and shipping processes. We map out high-traffic zones and determine the optimal robot-to-human ratio.

2. WMS Integration & Pilot: Our robots integrate directly with your Warehouse Management System (WMS) via API. We start with a pilot zone to validate navigation paths and task allocation logic without disrupting main operations.

3. Full-Scale Rollout: Once validated, the fleet is expanded. Traffic management software coordinates the robots to prevent congestion, while "opportunity charging" ensures 24/7 uptime during shift changes.

Success Stories

Global Retailer Reduces Pick Times by 40%

Challenge: During peak holiday seasons, temporary labor was unreliable, leading to delayed shipments.

Solution: Deployed a fleet of Goods-to-Person (GTP) robots.

Result: Order accuracy hit 99.9% and throughput nearly doubled.

Automating Pallet Movement in 200k sq/ft

Challenge: Excessive forklift traffic was causing safety incidents and bottlenecks at the loading dock.

Solution: Implementation of Autonomous Forklifts for long-haul transport.

Result: Zero safety incidents in Year 1 and 30% reduction in operational costs.

Operations in -20°F Environments

Challenge: Human workers could only work short shifts in deep freeze environments.

Solution: Cold-rated autonomous mobile robots for pallet storage and retrieval.

Result: Continuous 24/7 operation without environmental breaks.

Just-In-Time Manufacturing Supply

Challenge: Line-side delivery of parts was inconsistent, halting production.

Solution: Tugger robots following magnetic tape and LiDAR navigation.

Result: 100% uptime on line-side delivery and reduced WIP inventory.

Industry-Specific Questions

Do these robots require changes to existing racking infrastructure?

Generally, no. Most modern AMRs and autonomous forklifts use LiDAR and SLAM navigation, meaning they map the existing environment. They can navigate standard aisles and interact with existing pallet locations without requiring magnetic tape or floor bolts.

How do robots integrate with our WMS/ERP?

Our fleet management software utilizes standard REST APIs and supports common protocols like WMS interfaces (SAP, Oracle, Manhattan). Orders are pushed from your WMS to our fleet manager, which then assigns the most efficient robot for the task.

Are the robots safe to work alongside humans?

Yes. All robots comply with ANSI/RIA R15.08 safety standards. They are equipped with 360-degree LiDAR, 3D cameras, and emergency stops. They dynamically detect obstacles and people, slowing down or stopping instantly to prevent collisions.

What happens if the Wi-Fi connection is lost?

While Wi-Fi is needed for task assignment from the central server, the robots perform navigation and obstacle avoidance locally on-board. If connection is lost, they will safely complete their immediate move or pause safely until reconnection, ensuring no accidents occur.

How is charging managed for 24/7 operations?

We use "opportunity charging." Robots automatically dock for short bursts whenever they are idle or during scheduled breaks. For high-intensity operations, we can implement battery swapping or calculate fleet size to ensure a percentage of units are always charging while others work.

What is the typical payload capacity?

It varies by model. Small bin-carrying robots typically handle 50-100kg. Pallet transport AMRs can handle 1,000kg to 1,500kg. Heavy-duty autonomous forklifts can handle loads exceeding 3,000kg depending on the configuration.

Can they handle uneven floors or ramps?

Most AMRs require relatively smooth concrete floors. However, specific chassis are designed with suspension to handle expansion joints and ramps with up to a 5-8% grade. We assess floor quality during the initial site survey.

What is the ROI timeframe?

For multi-shift operations, the ROI is typically between 12 to 18 months. Savings come from reduced labor costs, lower recruitment/turnover expenses, decreased product damage, and increased throughput efficiency.

How long does deployment take?

A standard deployment takes 4-8 weeks. This includes site mapping, IT integration, workflow configuration, and on-site testing. Complex brownfield integrations may take slightly longer.

Can the robots work in dark warehouses?

Yes. LiDAR navigation does not depend on visible light. This allows for "lights-out" logistics operations, saving significant energy costs in fully automated zones.