Inventory Management & Stocktaking

Transform your warehouse operations with autonomous mobile robots designed for precise cycle counting and real-time inventory tracking. Eliminate manual errors, ensure 99.9% stock accuracy, and integrate seamlessly with your existing WMS to visualize data instantly.

Why Automate Inventory Management & Stocktaking?

99.9% Accuracy

Eliminate human error associated with manual counting. Robots provide consistent, objective data scanning via RFID or computer vision.

24/7 Operations

Perform stocktakes outside of business hours or during breaks. Robots work autonomously at night, ensuring data is ready by morning.

Real-Time Visibility

Bridge the gap between physical stock and digital records. Identify discrepancies instantly rather than waiting for quarterly audits.

High-Rack Reach

Extendable masts allow robots to scan inventory on high shelves without the safety risks associated with forklifts or ladders.

Cost Reduction

Significantly lower labor costs associated with manual counting and reduce losses from misplaced items or overstocking.

Safer Workflows

Keep human workers out of narrow aisles and high-traffic forklift zones by delegating repetitive scanning tasks to AMRs.

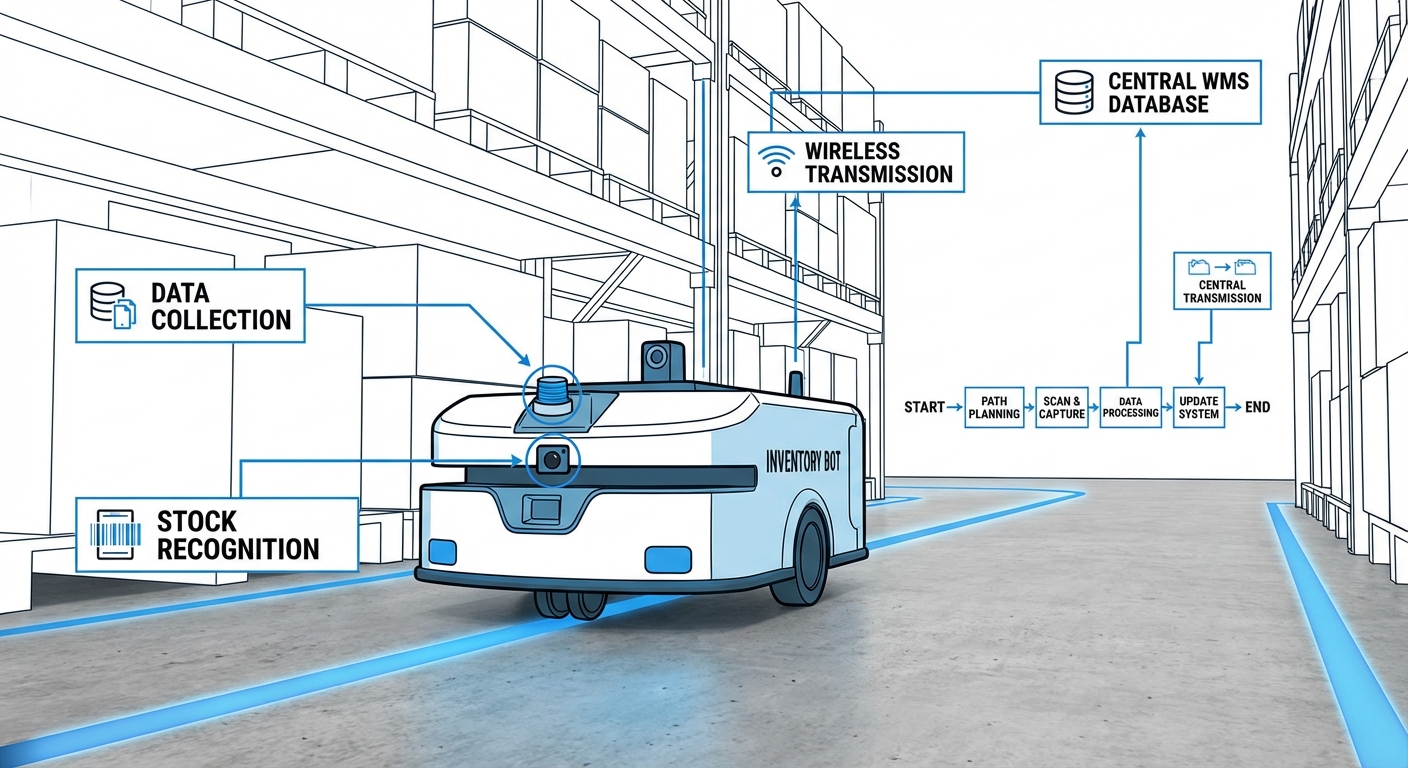

Intelligent Scanning & Navigation

The robot utilizes advanced SLAM (Simultaneous Localization and Mapping) to navigate warehouse aisles autonomously without physical guides. It identifies its location down to the centimeter, ensuring every rack location is visited.

Equipped with telescopic masts or drone-tethered systems, the robot carries high-resolution cameras and RFID readers. It scans barcodes (1D/2D) or detects RFID tags on pallets and individual cartons, capturing ID, location, and timestamp data.

This data is processed on the edge and synchronized immediately with your WMS/ERP system via Wi-Fi or 5G private networks. The system automatically highlights discrepancies, allowing warehouse managers to focus only on the exceptions rather than the routine count.

Where It's Used

Warehousing & 3PL

Ideal for high-volume distribution centers where cycle counting is a daily necessity. Robots handle full-pallet scanning in high-bay racking systems efficiently.

Retail & Supermarkets

Deployed during night shifts to scan store shelves for out-of-stock items, misplaced products, and price tag compliance.

Manufacturing

Tracks Work-in-Progress (WIP) and raw material availability on the production line, ensuring JIT (Just-in-Time) processes flow smoothly.

Cold Chain Storage

Robots operate reliably in freezer environments where manual counting is physically demanding and limited by human exposure time limits.

What You Need

Infrastructure

- ✓ Wi-Fi 6 or Private 5G Network

- ✓ Standardized Aisle Widths (>1m)

- ✓ Adequate Lighting (for vision systems)

- ✓ Flat Concrete Flooring

Robot Hardware

- ✓ Autonomous Mobile Robot (AMR) Base

- ✓ Telescopic Mast or Scissor Lift

- ✓ High-Res RGB & Depth Cameras

- ✓ UHF RFID Reader Arrays

Software & Integration

- ✓ WMS/ERP API Access

- ✓ Warehouse Digital Twin Map

- ✓ Fleet Management Server

- ✓ Inventory Analytics Dashboard

Frequently Asked Questions

How accurate is robotic stocktaking compared to humans?

Robotic stocktaking typically achieves accuracy rates exceeding 99.9%. Unlike humans, robots do not suffer from fatigue or distraction, ensuring consistent scanning quality regardless of shift length.

Does it work with Barcodes or only RFID?

Our solutions are versatile. We support UHF RFID for rapid, non-line-of-sight counting, as well as high-resolution Computer Vision for reading standard 1D/2D barcodes, QR codes, and even human-readable text labels.

How high can the robots reach?

Depending on the hardware configuration, our telescopic mast robots can scan shelves up to 10-12 meters high. For warehouses with even higher vertical storage, drone-integrated solutions are available.

Can the robots work safely alongside humans?

Yes. The robots are equipped with LiDAR and 3D depth cameras for obstacle avoidance. They are ISO 3691-4 compliant, meaning they will stop or reroute immediately upon detecting a person or object in their path.

Does this require changing our warehouse layout?

Generally, no. As long as your aisles meet the minimum width requirements (usually 1 meter) and the floor is relatively even, the robots map your existing layout. No magnetic tape or floor guidewires are needed.

What is the battery life?

Most units run for 8-12 hours on a single charge. They feature "opportunity charging" or autonomous docking, meaning they return to their station automatically when battery levels are low.

How long does implementation take?

Deployment is rapid. Mapping a 10,000 sq meter facility typically takes 1-2 days. Full WMS integration and testing can be completed within 2-4 weeks.

Can it detect damaged boxes?

Yes, advanced vision models can be trained to flag "exceptions" such as crushed boxes, open flaps, or leaning pallets, providing visual proof to managers alongside the inventory count.

Which WMS platforms do you support?

We support standard REST API and SOAP integrations for major platforms like SAP EWM, Oracle NetSuite, Manhattan Associates, and Blue Yonder, as well as custom in-house systems.

What is the ROI timeline?

Most facilities see a Return on Investment within 12 to 18 months, driven by labor savings, reduction in write-offs, and optimized stock levels.

Ready to implement Inventory Management & Stocktaking?

Deploy autonomous precision in your warehouse today.

Explore Our Robots