Assembly Line Transport

Revolutionize your manufacturing floor by automating the transfer of work-in-progress materials between stations. Enhance throughput, ensure just-in-time delivery, and free your human workforce for high-value tasks.

Why Automate Assembly Line Transport?

Maximized Throughput

Eliminate bottlenecks caused by manual transport. Robots deliver parts precisely when needed, keeping the line moving.

Enhanced Safety

Reduce forklift traffic and manual heavy lifting. AMRs utilize LiDAR and 3D cameras to navigate safely around workers.

24/7 Operations

Robots don't take breaks or change shifts. Enable lights-out manufacturing and continuous production cycles.

Scalable Flexibility

Easily reconfigure routes via software without magnetic tape or floor modifications as your production line evolves.

Accuracy & Traceability

Integrate with MES to track every movement. Ensure the right part arrives at the right station, reducing assembly errors.

Rapid ROI

Lower operational costs and increased output lead to a typical return on investment in less than 12 months.

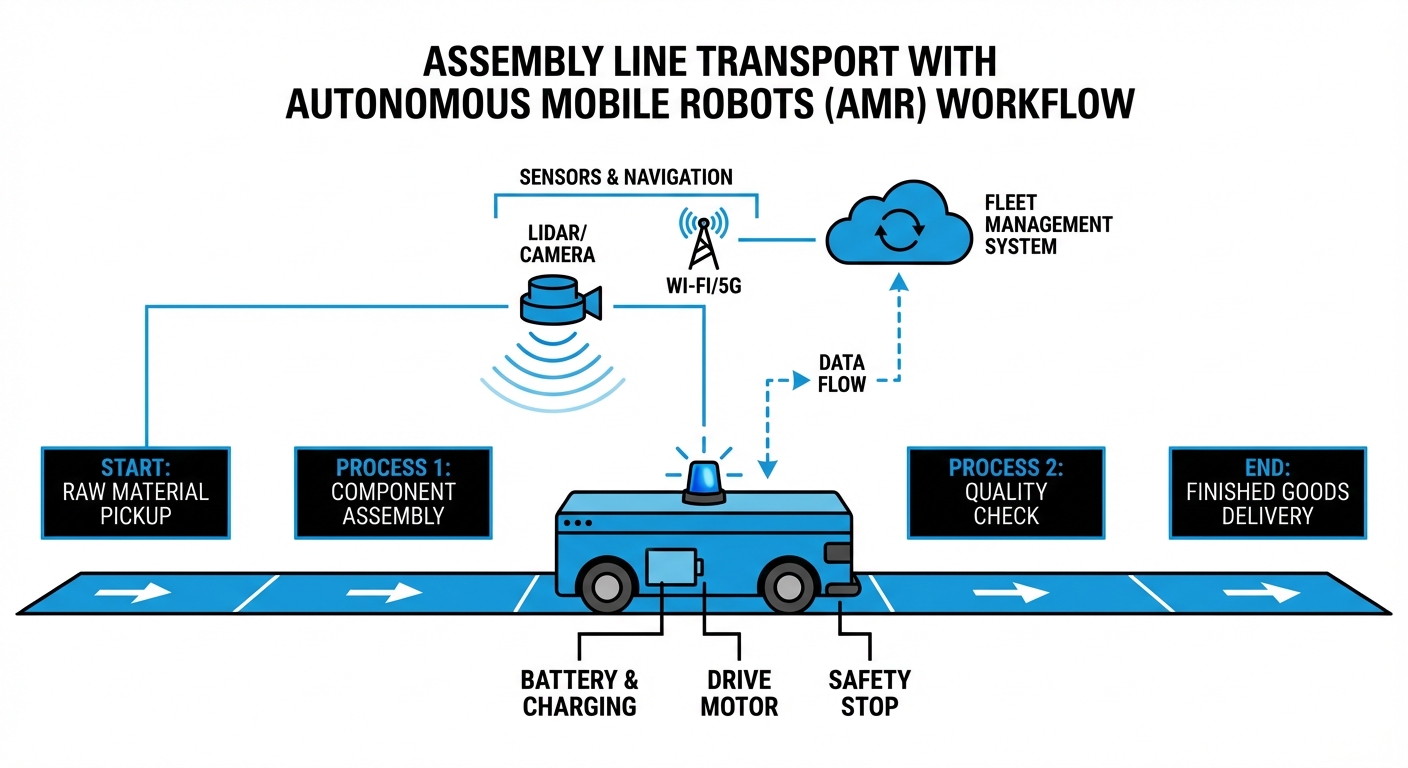

Seamless Integration into Your Workflow

The system begins by mapping your facility using SLAM (Simultaneous Localization and Mapping) technology. Once mapped, the fleet manager software integrates directly with your Manufacturing Execution System (MES).

When an assembly station completes a task or runs low on materials, a signal is sent to the fleet manager. The software instantly assigns the nearest available robot to transport the finished sub-assembly to the next stage or deliver fresh components from inventory.

Robots navigate dynamically, avoiding obstacles and recalculating paths in real-time. Upon arrival, they can interface with automated conveyors for hands-free transfer or dock precisely for manual offloading.

Where It's Used

Engine & Chassis Assembly

Moving heavy engine blocks between machining centers and final assembly lines without fixed conveyors, allowing for flexible model switching.

PCB & Component Transport

Delivering sensitive electronic components in ESD-safe racks from storage to SMT lines with vibration-controlled movement.

End-of-Line Packaging

Transporting finished goods from filling stations to palletizing robots, relieving bottlenecks in high-speed bottling and packaging plants.

Clean Room Logistics

Automating material transfer in ISO-certified clean rooms to reduce human contamination risks and ensure strict audit trails.

What You Need

| Hardware Infrastructure | Autonomous Mobile Robots (AMR) with appropriate payload capacity (50kg - 1500kg) and top-module attachments (rollers, lifters, or racks). |

| Connectivity | Industrial-grade Wi-Fi 6 or Private 5G network covering the entire transport area for real-time fleet communication. |

| Environment | Flat, even flooring (concrete, resin, or tile). Minimum aisle width of 20% greater than robot width. Marked charging zones. |

| Software Stack | Fleet Management Server, Navigation Client, and REST API integration with existing ERP/WMS/MES systems. |

| Safety Compliance | Adherence to ISO 3691-4 safety standards for driverless industrial trucks and risk assessment certification. |