Warehouse Material Transport

Streamline your internal logistics by automating the movement of goods between receiving, storage, and shipping zones. Reduce manual labor costs, minimize errors, and ensure 24/7 operational efficiency with autonomous mobile transport solutions.

Why Automate Warehouse Material Transport?

Cost Efficiency

Drastically reduce operational expenses by shifting human labor to high-value tasks while robots handle the repetitive hauling.

24/7 Productivity

Robots don't take breaks or sleep. Maintain continuous material flow across shifts to maximize throughput.

Enhanced Safety

Advanced LiDAR and vision systems prevent collisions, significantly reducing workplace accidents involving heavy machinery.

Scalable Operations

Easily scale your fleet up or down based on seasonal demand without the lead time of hiring and training staff.

Digital Integration

Seamlessly connects with your WMS/ERP systems for real-time tracking, inventory updates, and data-driven optimization.

Accuracy & Precision

Eliminate human error in material handling. Ensure the right parts get to the right location at the exact right time.

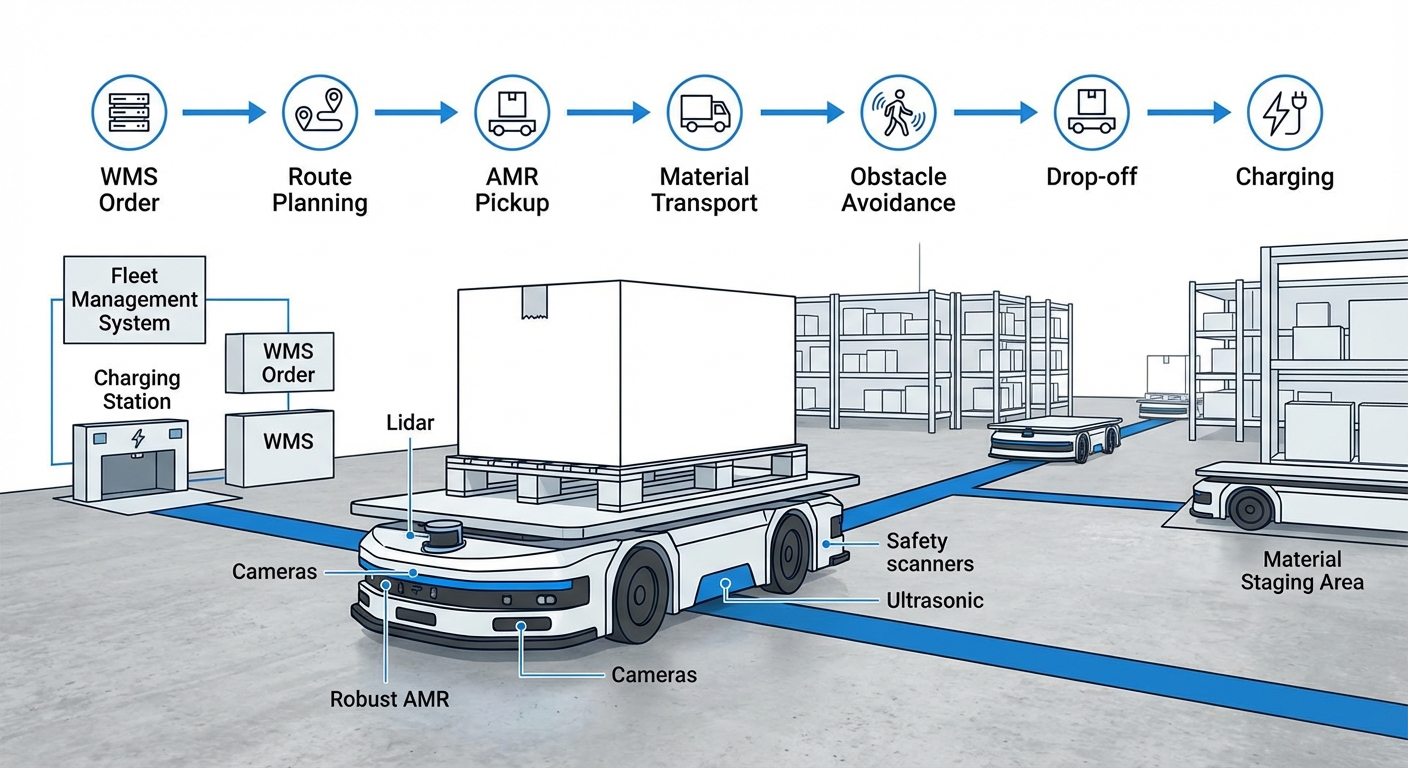

Autonomous Workflow Integration

Our warehouse transport robots utilize SLAM (Simultaneous Localization and Mapping) technology to navigate complex environments without the need for floor magnets or guide tapes. They create a dynamic map of your facility, updating it in real-time as obstacles move.

The process begins when your WMS triggers a transport request. The Fleet Management System assigns the task to the optimal robot based on battery level, proximity, and current payload.

Once loaded, the robot autonomously calculates the most efficient path, navigating around forklifts and pedestrians, delivers the payload to the designated drop-off point, and confirms delivery instantly to your central system.

Where It's Used

E-Commerce Fulfillment

Moving picked goods from aisles to packing stations. High-speed transport reduces cycle time and enables same-day shipping capabilities.

Automotive Manufacturing

Line-side replenishment. Delivering parts and sub-assemblies ("kitting") directly to the assembly line exactly when needed (Just-In-Time).

3PL Logistics

Cross-docking operations. Rapidly moving pallets from inbound receiving docks directly to outbound shipping lanes, bypassing storage.

Healthcare & Pharma

Secure transport of sensitive medical supplies or linens in hospitals, minimizing cross-contamination risks and ensuring audit trails.

What You Need

| Environment | Flat concrete or industrial flooring; Aisles minimum 1.2m width; WiFi coverage. |

| Infrastructure | Dedicated charging zones (approx 1m x 1m per dock); QR codes for high-precision docking (optional). |

| Network | Stable WiFi (2.4/5GHz) or Private 5G network for fleet management communication. |

| Software Stack | Fleet Manager (provided), API integration with existing WMS/ERP (REST/JSON), ROS 2 compliant. |

| Safety Standards | ISO 3691-4 compliance; Emergency Stop buttons; 360° LiDAR safety fields. |

Frequently Asked Questions

What is the difference between AGVs and AMRs?

AGVs (Automated Guided Vehicles) follow fixed paths like magnetic tape or wires. AMRs (Autonomous Mobile Robots) navigate freely using maps and sensors, allowing them to route around obstacles and easily adapt to changing floor plans without infrastructure changes.

Do I need to change my warehouse layout?

Generally, no. AMRs operate within existing layouts. However, you must ensure aisles are wide enough for the robot and load (typically 1.2m+) and keep paths reasonably clear of permanent blockage.

Are these robots safe to work alongside humans?

Yes. They are equipped with PL-d rated safety scanners, 3D cameras, and emergency stops. They automatically slow down or stop when a person or object enters their safety field.

What is the maximum payload capacity?

Payloads vary by model. Our lightweight carriers handle up to 100kg, while our heavy-duty pallet transporters can move up to 1,500kg.

How long does the battery last?

Most units run for 8-10 hours on a full charge. They support "opportunity charging," meaning they autonomously dock for 10-15 minutes during downtime to keep running 24/7.

Can they integrate with my WMS?

Absolutely. Our fleet management software offers a REST API that integrates with SAP, Oracle, Microsoft Dynamics, and other major WMS/ERP systems.

Does it work on multiple floors?

Yes, provided the robot can interface with the elevator controls via I/O modules or WiFi. The software handles multi-floor mapping and navigation.

What maintenance is required?

Maintenance is minimal compared to forklifts. Routine checks involve cleaning sensors, inspecting tires, and a bi-annual service check of the battery and motors.

How long does implementation take?

A typical deployment takes 2 to 6 weeks, depending on the fleet size and integration complexity. Mapping a facility can be done in just a few days.

Can I add custom top modules?

Yes. The robots have standard mounting holes and power interfaces. You can attach roller conveyors, shelving units, robotic arms, or pallet lifts.