Robotics in Construction & Mining

The construction and mining sectors are undergoing a pivotal shift towards autonomous operations and data-driven precision. From autonomous hauling to structural integrity scanning, robotics is redefining safety standards and operational efficiency in the world's most demanding environments.

Why Robotics Matters Here

Enhanced Worker Safety

Mining and construction sites are inherently hazardous. Robots take over dangerous tasks in unstable tunnels, high altitudes, and toxic environments, keeping human workers out of harm's way.

Addressing Labor Shortages

With a global decline in skilled tradespeople, autonomous machinery fills the gap, allowing projects to proceed on schedule despite workforce fluctuations.

Surveying Precision

Drone mapping and ground-based LiDAR provide millimeter-accurate topographical data, reducing rework costs and ensuring foundations are built correctly from day one.

24/7 Operations

Autonomous haulage systems and drilling rigs can operate continuously without breaks or shift changes, drastically reducing project timelines and increasing throughput.

Real-Time Data Integration

Robots connect directly to BIM (Building Information Modeling) and mine planning software, providing real-time progress updates and predictive maintenance alerts.

Sustainability & Efficiency

Precise robotic control leads to optimized fuel consumption in heavy machinery and reduced material waste during construction, supporting greener industry standards.

Applications in Construction & Mining

Construction Site Surveying

Learn how construction site surveying transforms construction & mining.

Explore Application →Mining Tunnel Inspection

Learn how mining tunnel inspection transforms construction & mining.

Explore Application →Inspection & Monitoring

Learn how inspection & monitoring transforms construction & mining.

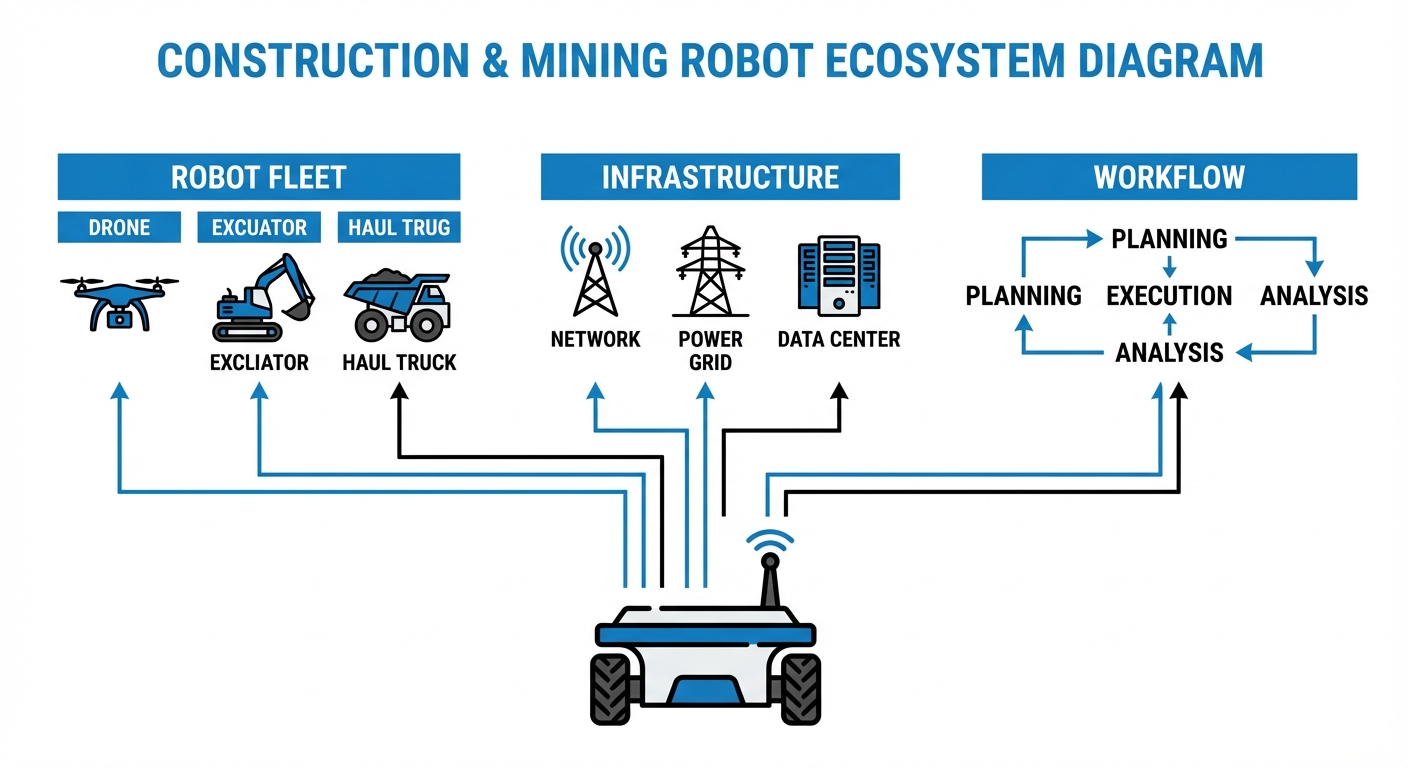

Explore Application →How to Deploy Robotic Solutions

Implementing robotics in heavy industries requires a strategic approach. It begins with a comprehensive site assessment to identify high-risk, repetitive tasks suitable for automation. We recommend starting with a pilot program—such as automated surveying or specific haulage routes—to benchmark performance against traditional methods.

Infrastructure readiness is the next critical step. For mining operations, specifically those underground, establishing a robust mesh network or private 5G connectivity is essential for the telemetry and low-latency control required by autonomous units.

Finally, workforce transformation is key. Successful deployment isn't just about hardware; it's about upskilling operators to become fleet managers and maintenance technicians. Our implementation model includes extensive training modules to ensure your team is ready to manage the robotic ecosystem effectively.

Success Stories

Autonomous Haulage at Depth

Challenge: Excessive downtime due to shift changes and ventilation requirements in a 2km deep mine.

Solution: Deployed a fleet of autonomous electric loaders.

Result: 35% increase in ore extraction and zero LTI (Lost Time Injuries) over 24 months.

BIM Verification Drones

Challenge: Significant rework costs caused by undetected structural deviations in a high-rise project.

Solution: Daily autonomous drone flights comparing LiDAR scans to BIM models.

Result: Detected 12 critical errors early, saving estimated $2.4M in rework and materials.

Robotic Rebar Tying

Challenge: Labor shortages delaying a major bridge foundation project.

Solution: Integrated gantry-based rebar tying robots.

Result: Tying speed increased by 2.5x, allowing the project to get back on schedule within three weeks.

Precision Drilling

Challenge: Inconsistent blast fragmentation leading to inefficient crushing.

Solution: GPS-guided autonomous drilling rigs.

Result: Improved fragmentation consistency by 20%, reducing downstream energy consumption by 15%.

Industry-Specific Questions

Are these robots durable enough for mining environments?

Yes. Our construction and mining robots are rated IP67 or higher, designed with reinforced chassis, dust-proof sealing, and shock-absorbing systems specifically engineered to withstand heavy vibration, impact, and extreme temperatures found in mines and active construction sites.

How do robots handle GPS-denied environments like tunnels?

For underground or indoor environments where GPS is unavailable, our systems utilize SLAM (Simultaneous Localization and Mapping) technology combined with LiDAR and inertial measurement units (IMUs) to navigate with centimeter-level precision.

What is the typical ROI timeline?

While initial capital expenditure is higher than traditional machinery, the reduction in downtime, fuel savings, and increased productivity typically results in an ROI within 18 to 24 months, depending on the scale of deployment.

How does this integrate with current safety protocols?

Robots are programmed with strict geofencing and collision avoidance protocols. They are designed to operate alongside mixed fleets (human and machine) and adhere to ISO safety standards for autonomous industrial systems.

Can the robots be integrated with BIM software?

Absolutely. Data interoperability is a core feature. Our systems can export point clouds and progress data directly into major BIM and mine planning software suites like Autodesk, Bentley, and Deswik.

What connectivity infrastructure is required?

For real-time teleoperation and data offloading, a private LTE/5G network or a robust industrial Wi-Fi mesh is recommended. However, most units are capable of autonomous operation with store-and-forward data capabilities if connection is lost.

How is maintenance handled?

We offer predictive maintenance packages where the robots self-diagnose issues. We also provide training for your on-site mechanics to handle routine servicing, with specialized support available for sensor and software issues.

Does this replace human workers?

The primary goal is to remove humans from dangerous and repetitive tasks. This shift allows your workforce to upskill into supervisory, maintenance, and data analysis roles, which are safer and higher-value positions.

What about battery life and charging?

Our electric units support opportunity charging and battery swapping. For continuous 24/7 operations, systems are programmed to autonomously return to charging docks during micro-downtimes or shift rotations.

Is data security guaranteed?

Yes, all data transmission is encrypted using industrial-grade standards. We offer on-premise deployment options for high-security sites where data must not leave the local network.