Mining Tunnel Inspection

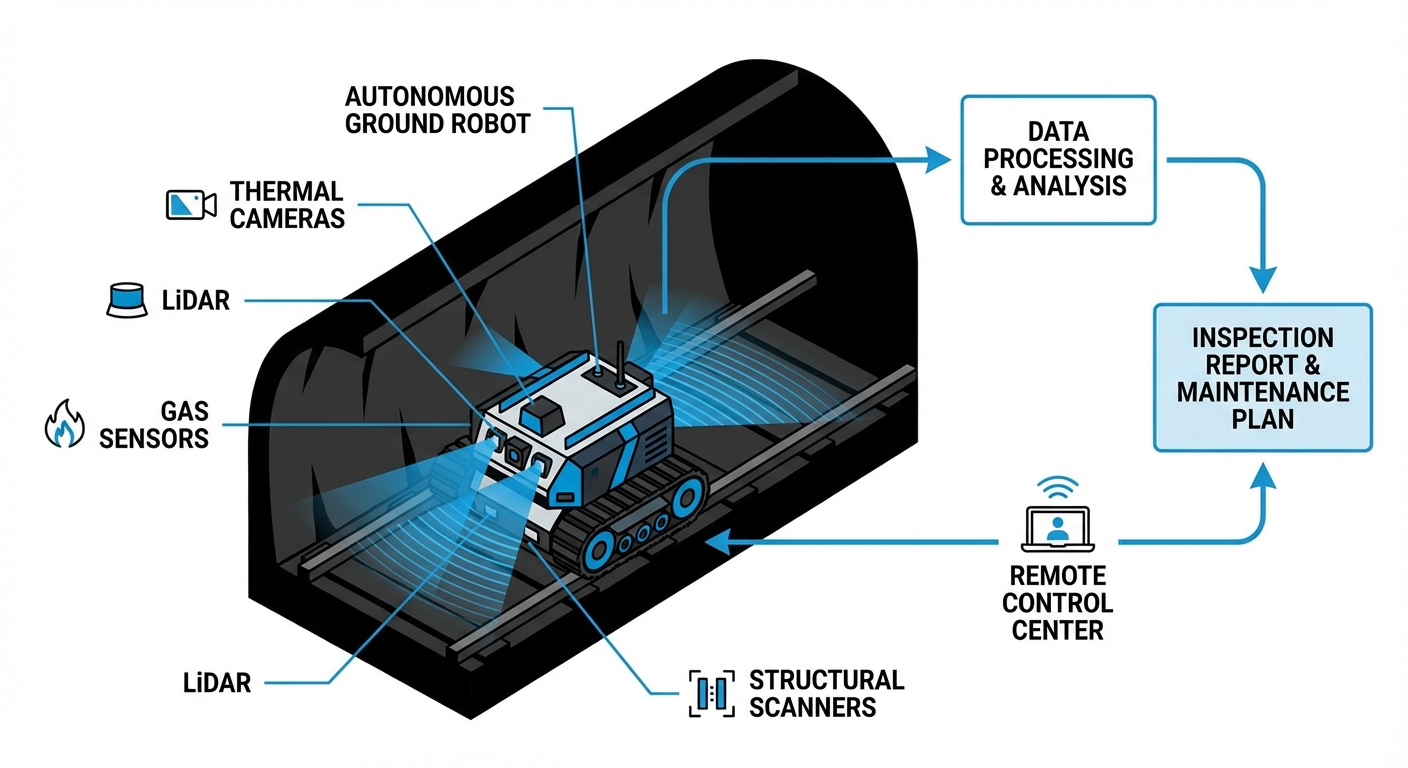

Deploy autonomous mobile robots equipped with advanced LIDAR and photogrammetry to perform consistent, high-precision structural integrity assessments in underground environments. Eliminate human risk while capturing digital twins of tunnel infrastructure.

Why Automate Mining Tunnel Inspection?

Zero Human Risk

Keep personnel out of unstable, toxic, or deep underground areas. Robots handle the dangerous initial scans and routine checks.

Digital Twin Creation

Generate millimeter-accurate 3D point clouds and thermal maps to create a living digital twin of the mine's infrastructure.

Consistent Data

Automated routes ensure that inspections are performed from the exact same vantage points every time, enabling precise change detection.

24/7 Availability

Robots can operate during blast clearing times or shift changes, ensuring maximum asset utilization without downtime.

Multi-Hazard Detection

Simultaneously monitor for structural cracks, water leaks, methane buildups, and temperature anomalies in a single pass.

Cost Efficiency

Reduce insurance premiums and expensive manual survey contracting costs while preventing catastrophic infrastructure failures.

Autonomous Underground Navigation

Mining environments are GPS-denied and featureless, making traditional navigation impossible. Our solution utilizes 3D SLAM (Simultaneous Localization and Mapping) powered by high-density LIDAR sensors.

The robot constructs a real-time map of the tunnel walls, identifying its position with centimeter-level accuracy. As it traverses the mine, it fuses data from Inertial Measurement Units (IMUs) and wheel odometry to maintain stability on uneven terrain.

Data is processed at the edge using onboard NVIDIA Jetson modules to identify immediate hazards, while full-resolution datasets are uploaded to the surface control center via mesh Wi-Fi or saved for post-mission analysis.

Where It's Used

Active Ore Mining

Daily inspection of haulage drifts and conveyer belt tunnels to detect wall convergence or hanging wall instability before it endangers workers.

Abandoned Mine Reclamation

Safely mapping flooded or toxic abandoned shafts to assess environmental risks and structural integrity without sending humans inside.

Civil Infrastructure Tunnels

Inspecting subway systems, utility tunnels, and sewage systems for corrosion, water ingress, and concrete spalling.

Disaster Response

Rapid deployment following seismic events or cave-ins to assess route viability for rescue teams.

What You Need

| Component | Specification Requirement |

|---|---|

| Robot Chassis | Ruggedized IP65+ rover or quadruped with high ground clearance |

| Primary Sensor | 3D LIDAR (100m+ range, 360° FOV) |

| Environmental Sensors | Gas detector (CO, CH4, O2), Thermal Camera, Humidity Sensor |

| Compute | Edge AI Processor (e.g., NVIDIA Jetson Orin) for real-time SLAM |

| Connectivity | Mesh Wi-Fi nodes or Store-and-Forward capability |

Frequently Asked Questions

How does the robot navigate without GPS?

The robot uses LIDAR-based SLAM (Simultaneous Localization and Mapping). It builds a 3D map of the tunnel environment in real-time and calculates its position relative to the walls and features it scans, achieving localization accuracy within a few centimeters.

Can the robot handle wet or muddy terrain?

Yes. Depending on the chassis selected (wheeled rover vs. quadruped), our solutions are rated IP65 or higher and designed with high torque and aggressive tread patterns to navigate mud, standing water (up to chassis height), and loose gravel typical in mining environments.

What is the battery life for a typical mission?

Typical runtimes range from 2 to 4 hours depending on the payload and terrain difficulty. For continuous 24/7 operations, we offer automated docking stations for opportunistic charging or hot-swappable battery configurations.

Does the robot detect hazardous gases?

Yes, the sensor payload is modular. Most mining configurations include a multi-gas detector capable of sensing Methane, Carbon Monoxide, Hydrogen Sulfide, and Oxygen levels, triggering alerts if thresholds are breached.

How is data retrieved from deep underground?

If a Wi-Fi mesh network exists, data streams in real-time. In disconnected areas, the robot stores all data (up to terabytes) locally and auto-uploads it once it returns to a communications access point.

Can it detect cracks in the tunnel ceiling?

Yes. High-resolution photogrammetry cameras combined with dense LIDAR point clouds allow for the detection of structural fissures, rock bolt failures, and concrete spalling, often with better clarity than a human eye in low light.

Is lighting required in the tunnel?

LIDAR works in total darkness. For visual cameras, the robot carries its own high-intensity LED array to illuminate the surroundings for photography and video feeds.

How fast does the robot move?

Inspection speeds are typically slow (0.5 to 1.5 m/s) to ensure high-fidelity data capture. Transit speeds between inspection zones can be higher, up to 2.5 m/s depending on the platform.

What happens if the robot gets stuck?

The robots feature autonomous recovery behaviors (backing up, rotating). If physically trapped, it broadcasts a distress beacon with its last known location. Teleoperation is also available if connectivity permits.

Is the equipment explosion-proof?

We offer ATEX/IECEx certified enclosures for environments with explosive atmospheres (Zone 1/Zone 2) to ensure the robot cannot ignite combustible gases or dust.

Ready to implement Mining Tunnel Inspection?

Enhance safety and digitize your underground assets today.

Explore Our Robots