Inspection & Monitoring

Deploy autonomous systems to perform critical checks in hazardous or hard-to-reach environments. Ensure consistent quality control and asset integrity while significantly reducing risk to human personnel.

Why Automate Inspection & Monitoring?

Enhanced Safety

Remove humans from hazardous environments involving radiation, toxic gases, or extreme temperatures.

High Precision

Advanced sensors detect defects, thermal anomalies, or leaks with higher accuracy than the human eye.

Cost Efficiency

Reduce downtime and insurance costs while minimizing the need for expensive safety infrastructure.

Continuous Operation

Execute monitoring routines 24/7 without fatigue, ensuring no critical event goes unnoticed.

Data Analytics

Convert physical inspections into digital data streams for predictive maintenance and trend analysis.

Real-time Alerts

Instantaneously notify central command when readings exceed safe thresholds, allowing faster response.

Autonomous Workflow Integration

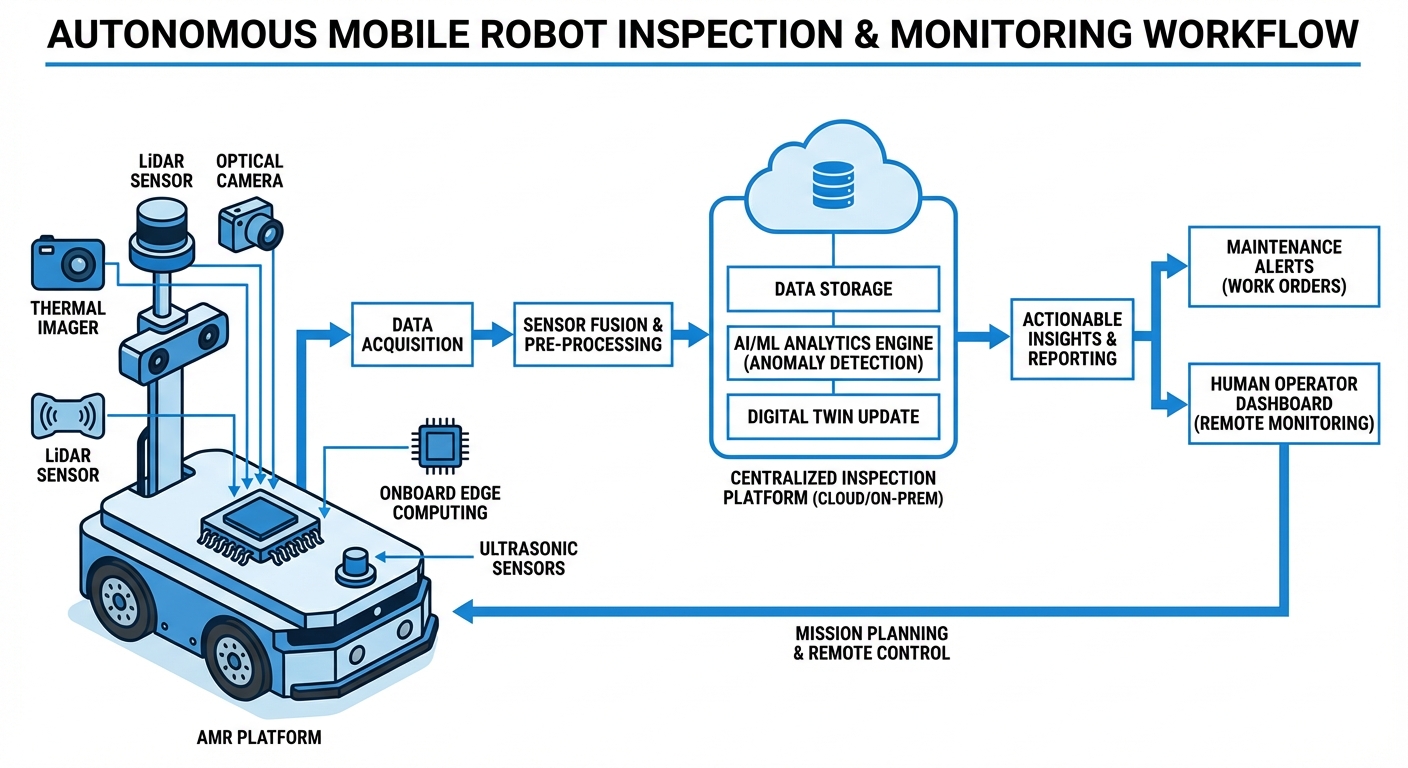

The robot utilizes SLAM (Simultaneous Localization and Mapping) to navigate complex facilities without GPS. It follows pre-determined patrol routes or can be teleoperated for spot checks.

Equipped with a multi-sensor payload—including 360° LiDAR, thermal cameras, and gas sniffers—the system captures environmental data in real-time. Edge computing processes this data instantly to identify anomalies like hotspots, leaks, or intruders.

Finally, data is synchronized with your central dashboard or SCADA system, providing a digital twin of your facility's current status and generating automated compliance reports.

Where It's Used

Oil & Gas

Automated inspection of pipelines, pressure vessels, and offshore rigs. Robots detect methane leaks and read analog gauges in remote locations.

Energy & Utilities

Substation monitoring and power line inspection. Thermal imaging identifies overheating transformers before failure occurs.

Civil Infrastructure

Bridge, tunnel, and dam inspections. Drones or climbers map structural integrity and detect surface cracks or corrosion.

Manufacturing & Warehousing

Inventory cycle counting and safety patrols. Ensuring aisles are clear and fire safety equipment is accessible.

What You Need

| Core Sensors | LiDAR (2D or 3D), RGB Depth Cameras, IMU |

| Specific Payloads | Thermal/IR Cameras, Ultrasonic sensors, Gas Analyzers, Acoustic sensors |

| Robot Capabilities | IP54+ rating (for outdoor), Obstacle Avoidance, Auto-docking/charging |

| Software Stack | ROS/ROS2 compatibility, Fleet Management Dashboard, Computer Vision API |

| Connectivity | WiFi 6, 4G/5G LTE module, or Local Mesh Network |

Frequently Asked Questions

What types of environments can the inspection robot handle?

Our robots are designed for versatile deployment. We have models rated for indoor warehousing (IP20) as well as ruggedized outdoor units (IP65/IP67) capable of withstanding rain, dust, and uneven terrain typical in industrial sites.

Can the robot read analog gauges?

Yes. Utilizing high-resolution optical cameras and onboard Computer Vision (AI), the robot can identify gauges, read the needle position, and digitize the value instantly.

Does the robot require continuous Wi-Fi?

No. The robot is capable of performing autonomous missions completely offline, storing data locally. It will upload the collected data once it returns to a connectivity zone or the docking station.

What is the typical battery life?

Depending on the payload and terrain, typical runtime is between 4 to 8 hours. However, the system supports autonomous "opportunity charging," meaning it will return to its dock to recharge automatically between missions.

How does it handle stairs or vertical obstacles?

Standard wheeled AMRs require ramps or elevators. For multi-level facilities without elevators, we offer quadruped (legged) robots that can climb stairs and traverse unstructured terrain.

Is it safe to operate around humans?

Absolutely. The robots feature redundant safety systems, including LiDAR and 3D depth cameras, to detect people and obstacles instantly, stopping or navigating around them to ensure safety.

Can I integrate this with my SCADA system?

Yes, we provide robust APIs and standard industrial protocol support (Modbus, MQTT, OPC UA) to integrate robot data directly into your existing control systems and dashboards.

Can the robot detect gas leaks?

Yes, when equipped with the optional gas analyzer payload, the robot can detect specific volatile organic compounds (VOCs), methane, and other hazardous gases, creating a heat map of concentration levels.

How long does it take to set up?

Initial mapping of a facility typically takes a few hours. Defining inspection points and missions can be done in 1-2 days depending on the complexity and size of the site.

What happens if the robot gets stuck?

The robot will attempt to re-route automatically. If it cannot find a path, it will alert the operator via the fleet management dashboard, who can then take manual control via teleoperation to clear the obstacle.