Robotics in Agriculture & Farming

The agricultural sector is undergoing a massive transformation known as Agriculture 4.0, driven by autonomous systems and data-driven robotics. From precision planting to autonomous harvesting, robotics addresses critical labor shortages while optimizing yield and sustainability through targeted resource application.

Why Robotics Matters Here

Labor Shortages

Challenge: An aging workforce and lack of seasonal labor threaten harvest timelines.

Solution: Autonomous harvesters and pickers operate 24/7, ensuring crops are gathered at peak ripeness regardless of labor availability.

Precision Resource Use

Challenge: Over-spraying chemicals and wasting water drives up costs and damages the environment.

Solution: Robots use computer vision to apply water, fertilizer, and pesticides only to specific plants that need them (Spot Spraying).

Soil Health

Challenge: Heavy traditional machinery compacts soil, reducing aeration and root growth.

Solution: Swarms of smaller, lightweight autonomous robots perform tasks without damaging soil structure.

Yield Consistency

Challenge: Variable conditions across large fields lead to inconsistent crop quality.

Solution: Data-gathering robots map fields in real-time, allowing for micro-management of specific zones to normalize yield.

Weed Control

Challenge: Herbicide-resistant weeds are becoming harder to manage with chemicals alone.

Solution: Mechanical weeding robots physically remove weeds or use laser ablation, reducing chemical dependency.

Livestock Management

Challenge: Monitoring the health and location of thousands of animals is manually impossible.

Solution: Drones and ground robots monitor grazing, herd movement, and detect early signs of illness automatically.

Applications in Agriculture & Farming

Agriculture Crop Monitoring

Learn how agriculture crop monitoring transforms agriculture & farming through multispectral analysis and real-time growth tracking.

Explore Application →Precision Spraying

Learn how precision spraying transforms agriculture & farming by targeting individual weeds and reducing chemical costs by up to 90%.

Explore Application →Inspection & Monitoring

Learn how inspection & monitoring transforms agriculture & farming by automating infrastructure checks and livestock tracking.

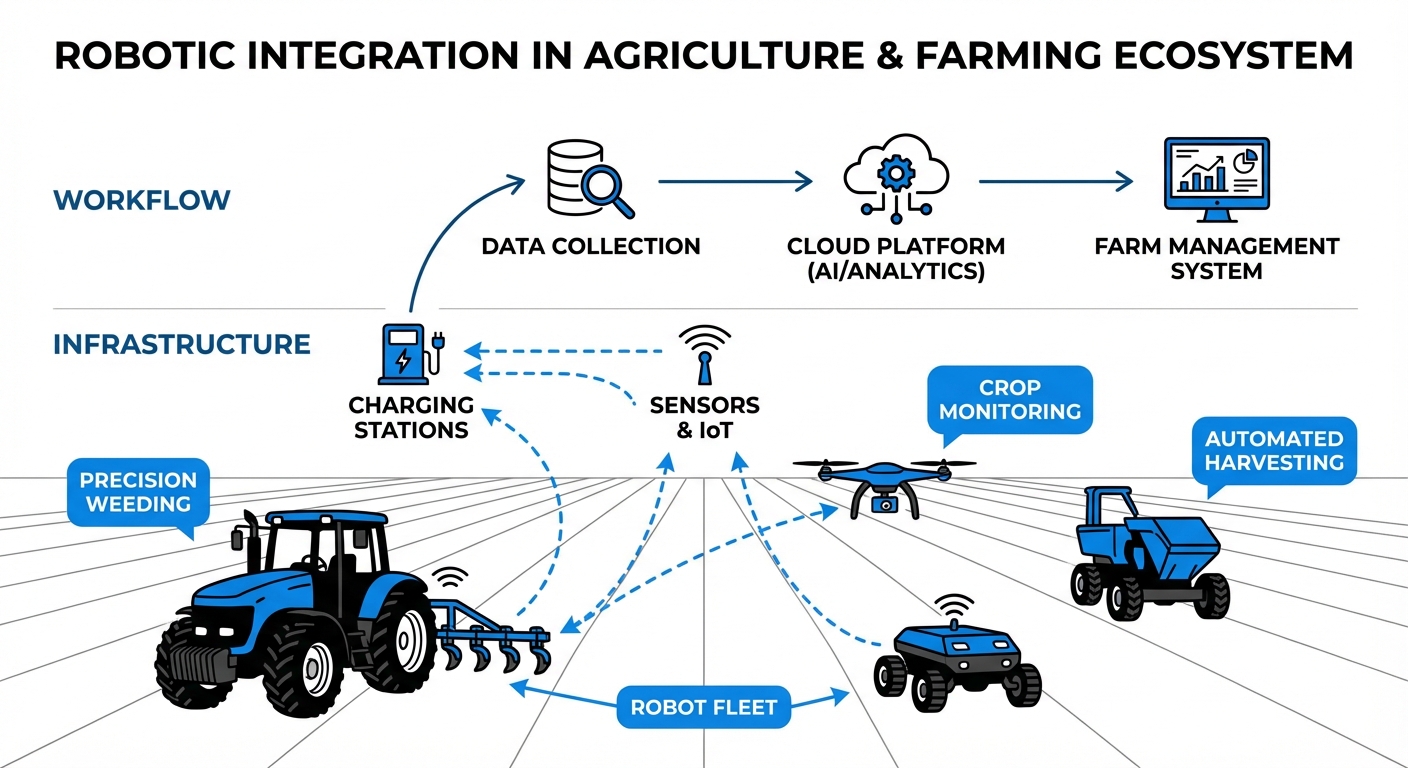

Explore Application →How to Deploy Robotic AgTech

Implementing robotics in agriculture requires a strategic approach to ensure ROI and seamless integration with existing farm management systems. The transition involves more than just buying hardware; it requires a digital transformation of the farm's workflow.

1. Connectivity Assessment: Robots require reliable GPS (RTK) and cellular or private 5G networks to navigate and transmit data. Ensuring your fields have coverage is the first step.

2. Task Audit: Identify high-repetition, low-skill tasks (like weeding) or high-precision needs (like seeding) where automation yields the fastest payback.

3. Interoperability: Select platforms that adhere to ISOBUS standards or open APIs to ensure your robots can "talk" to your existing tractors and farm management software (FMS).

Success Stories

Washington Apple Producer

Challenge: 40% of crop left on trees due to severe seasonal labor shortage.

Solution: Deployed a fleet of 6 autonomous vacuum-harvesting robots working 20 hours a day.

Result: 98% harvest completion rate and 15% reduction in bruised fruit.

Midwest Corn & Soy Farm

Challenge: Herbicide-resistant "superweeds" increasing chemical costs by 300%.

Solution: Implemented solar-powered laser weeding robots that patrol fields autonomously.

Result: Chemical usage dropped by 85%, creating a net ROI within 18 months.

Napa Valley Estate

Challenge: Need for precise, consistent pruning to ensure premium grape quality.

Solution: Used vision-based robotic arms for precision pruning based on 3D vine modeling.

Result: Standardized yield quality and reduced pruning time by 50%.

Vertical Greens Co.

Challenge: High transmission of plant pathogens due to human handling.

Solution: Fully automated seeding, transplanting, and harvesting via gantry robots.

Result: Zero contamination incidents in 2 years and 30% higher planting density.

Industry-Specific Questions

What is the typical ROI timeline for agricultural robots?

ROI varies by crop and robot type. For high-value specialty crops (strawberries, vineyards), ROI can be seen in as little as 12-18 months due to labor savings. For row crops utilizing autonomous weeding or precision spraying, the ROI typically ranges between 2 to 3 years based on chemical savings.

Can robots operate in adverse weather conditions like rain or mud?

Most modern agricultural robots are IP65 or IP67 rated, allowing operation in light rain and dust. However, heavy mud can impede smaller wheel-based robots. Track-based systems and lighter swarm robots are designed specifically to operate in fields where heavy tractors would get stuck or cause compaction.

Do I need reliable internet coverage in all my fields?

While real-time data streaming requires connectivity, many robots operate "on the edge," meaning they process data locally on the machine. However, for GPS RTK (precision navigation) and safety alerts, a base level of connectivity (Cellular, LoRaWAN, or private farm Wi-Fi) is usually required.

Can these robots be integrated with my existing John Deere/CNH equipment?

Increasingly, yes. Many retrofit kits allow existing tractors to become autonomous. Furthermore, ISOBUS standards help ensure that smart implements (like robotic sprayers) can communicate with standard tractor terminals.

How is safety managed for autonomous robots in open fields?

Agricultural robots use a combination of LiDAR, radar, cameras, and ultrasonic sensors to detect obstacles (humans, animals, poles). They are programmed to stop immediately upon detection. Geo-fencing also keeps them strictly within defined field boundaries.

Are robots suitable for small or medium-sized farms?

Yes. In fact, "Robotics as a Service" (RaaS) models are emerging, allowing smaller farms to rent capacity during peak seasons without the capital expenditure of purchasing the hardware outright.

What maintenance skills does my team need?

Basic maintenance (cleaning sensors, charging, swapping batteries) is simple. However, troubleshooting software or complex mechanical issues usually requires support from the vendor. Most vendors provide remote diagnostic support.

How do robots handle crop variety and irregular planting?

AI models are trained on millions of images to recognize specific crops vs. weeds. For harvesting, vision systems determine ripeness and orientation. Unstructured environments remain a challenge, which is why precision planting is often a prerequisite for robotic harvesting.

What power sources do these robots use?

It varies. Small scout/weeding robots are often battery-electric or solar-assisted. Large autonomous tractors may still utilize diesel-electric hybrids for torque, though the trend is moving toward full electrification to reduce carbon footprints.

Who owns the agronomic data collected by the robots?

Data ownership is a critical legal topic. Reputable vendors stipulate that the farmer owns their field data, while the vendor may use anonymized aggregate data to improve their AI models. Always review the End User License Agreement (EULA).

Ready to transform Agriculture & Farming?

Join the revolution of automated, sustainable, and data-driven farming.

Explore Our Robots