Ultrasonic Range Finders

Unlock precise obstacle detection and navigation for AGVs using sound waves. Learn how ultrasonic sensors provide reliable, cost-effective spatial awareness in diverse industrial environments.

Core Concepts

Time of Flight (ToF)

The fundamental principle where distance is calculated by measuring the time elapsed between emitting a sound pulse and receiving its echo.

The Blind Zone

The minimal distance near the sensor face where objects cannot be detected accurately because the sensor is still vibrating from transmission.

Beam Angle

Ultrasonic sensors emit sound in a cone shape. A wider beam covers more area but may detect unwanted peripheral obstacles.

Acoustic Impedance

The resistance of a medium to sound flow. Hard surfaces reflect sound well (high detection), while soft fabrics absorb it (poor detection).

Cross-Talk

Interference occurring when multiple sensors are fired simultaneously, causing one sensor to receive the echo of another.

Resolution

The smallest change in distance the sensor can detect, usually determined by the frequency of the sound wave and processing electronics.

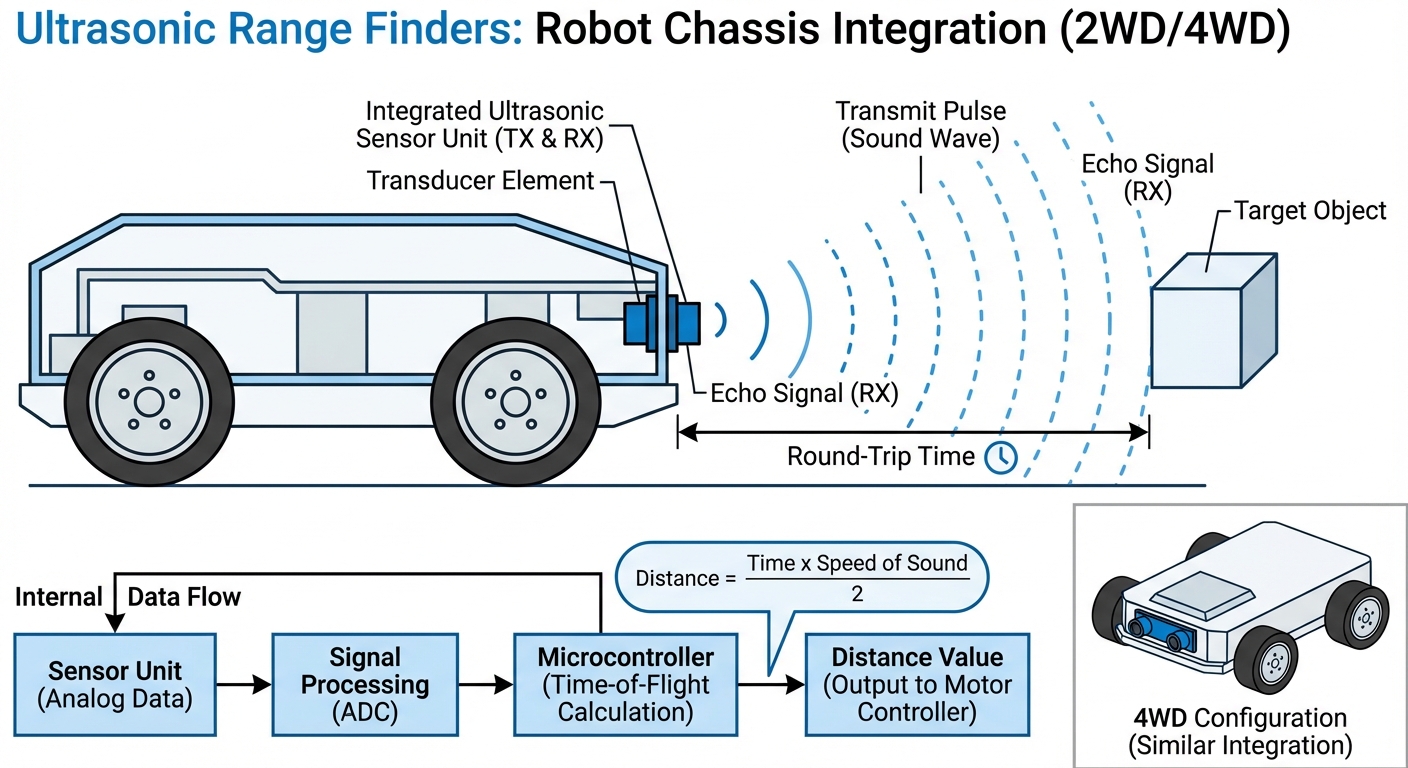

How It Works: The Physics of Sound

Ultrasonic sensors, typically operating at 40kHz (beyond human hearing), function similarly to biological echolocation used by bats. The process begins when the AGV controller sends a trigger signal to the sensor.

The sensor emits a short burst of ultrasonic pulses (usually 8 cycles). These waves travel through the air at approximately 343 meters per second. When the waves hit an object—such as a warehouse pallet or a wall—they bounce back towards the sensor.

The sensor detects this echo and outputs a high digital signal corresponding to the time taken. The robot's microcontroller calculates distance using the formula: Distance = (Time × SpeedOfSound) / 2. The division by 2 accounts for the round-trip journey of the sound wave.

Real-World Applications

Collision Avoidance

Acting as a "safety bumper," ultrasonic sensors detect unexpected obstacles in an AGV's path, triggering emergency stops or deceleration protocols to prevent accidents in busy warehouses.

Wall Following Navigation

Simple robots use side-mounted sensors to maintain a constant distance from a wall, allowing for map-less navigation through corridors without complex SLAM algorithms.

Transparent Object Detection

Unlike LiDAR or Infrared sensors which pass through glass or clear plastic, ultrasonic sound waves reflect off solid surfaces regardless of transparency, making them ideal for bottling plants.

Pallet & Load Detection

Sensors mounted on forklift forks can confirm the presence of a pallet or measure the distance to the load face to ensure proper engagement before lifting.

Frequently Asked Questions

How does an ultrasonic sensor differ from LiDAR?

LiDAR uses light (lasers) to measure distance, offering extremely high resolution and speed, but at a higher cost. Ultrasonic sensors use sound; they are cheaper and better at detecting transparent surfaces like glass, but have lower resolution and slower update rates.

What is the maximum effective range for standard AGV sensors?

Most industrial-grade ultrasonic sensors effective for AGVs function well between 2cm and 4 meters (approx. 13 feet). While some specialized sensors can reach further, reliability decreases significantly with distance due to sound dispersion.

Can ultrasonic sensors detect soft objects like foam or cloth?

Detection is difficult with soft materials. Materials with low acoustic impedance, like foam, sponges, or heavy fabric, tend to absorb the sound waves rather than reflect them, potentially causing the object to remain invisible to the sensor.

How does temperature affect sensor accuracy?

The speed of sound changes with air temperature (approx. +0.6 m/s per degree Celsius). Without temperature compensation logic in your code, an AGV operating in a freezing cold storage unit vs. a hot warehouse could have measurement errors of several centimeters.

What is "Crosstalk" and how do I prevent it?

Crosstalk happens when Sensor A receives the echo from Sensor B's transmission. To prevent this, you should chain your sensor triggers sequentially (fire A, wait for echo, fire B) rather than firing all sensors simultaneously.

Can these sensors work through dust or smoke?

Yes, this is a major advantage over optical sensors. Because sound waves constitute mechanical energy, they can propagate through dusty, smoky, or misty environments where light-based sensors (cameras, LiDAR) would be blinded.

What happens if the angle of incidence is too steep?

If the sound wave hits a smooth surface at a sharp angle (usually greater than 45 degrees), the wave may deflect away from the sensor instead of bouncing back. This results in the object not being detected, known as "specular reflection."

Why is there a minimum detection distance (Blind Spot)?

After emitting a pulse, the transducer membrane vibrates (rings) for a short period. During this "ringing down" time, the sensor cannot distinguish between the residual vibration and a returning echo, creating a blind zone usually between 2cm and 4cm.

Are ultrasonic sensors affected by ambient noise?

Generally, no. Common industrial noise is much lower frequency than the 40kHz+ used by these sensors. However, specific high-frequency pneumatic hissing or other ultrasonic equipment can cause interference.

How often should I poll the sensor (Sample Rate)?

Because sound is slow compared to light, you must wait for the echo to return before firing again. For a max range of 4m, the round trip takes approx 24ms. Therefore, a safe polling rate is usually around 20-40Hz per sensor.

What is the typical cone angle width?

Standard sensors have a detection cone of about 15° to 30°. For AGVs, a narrower beam is often preferred for precision mapping, while a wider beam is better for general collision avoidance bumpers.

Can ultrasonic sensors detect liquid levels?

Yes, they are excellent for this. Because liquids present a flat, hard surface to sound waves, ultrasonic sensors are frequently used in tank robots to monitor fluid levels without making physical contact with chemicals.