Tethered Power Systems

Unlock unlimited runtime and reduce onboard weight by supplying continuous power and high-speed data through physical umbilicals. Tethered systems offer a robust solution for high-demand AGVs and stationary manipulation tasks where battery constraints are non-negotiable.

Core Concepts

Infinite Runtime

By eliminating reliance on stored energy, tethered robots can operate 24/7 without downtime for charging or battery swapping cycles.

High-Bandwidth Data

The tether acts as a physical conduit for Fiber Optic or Ethernet, enabling latency-free transmission of 4K video and massive sensor clouds.

Weight Reduction

Removing heavy lithium-ion battery packs drastically increases the payload-to-weight ratio, allowing smaller actuators to lift heavier loads.

Tether Management

Automated spools and active tension control systems prevent cable tangling and reduce drag on the mobile robot during movement.

Operational Safety

Hardwired E-Stop circuits within the tether provide an immediate, fail-safe cutoff mechanism that wireless systems cannot match in reliability.

Slip Ring Technology

Advanced electrical rotary joints (slip rings) allow the spool to rotate freely while maintaining continuous electrical connection to the power source.

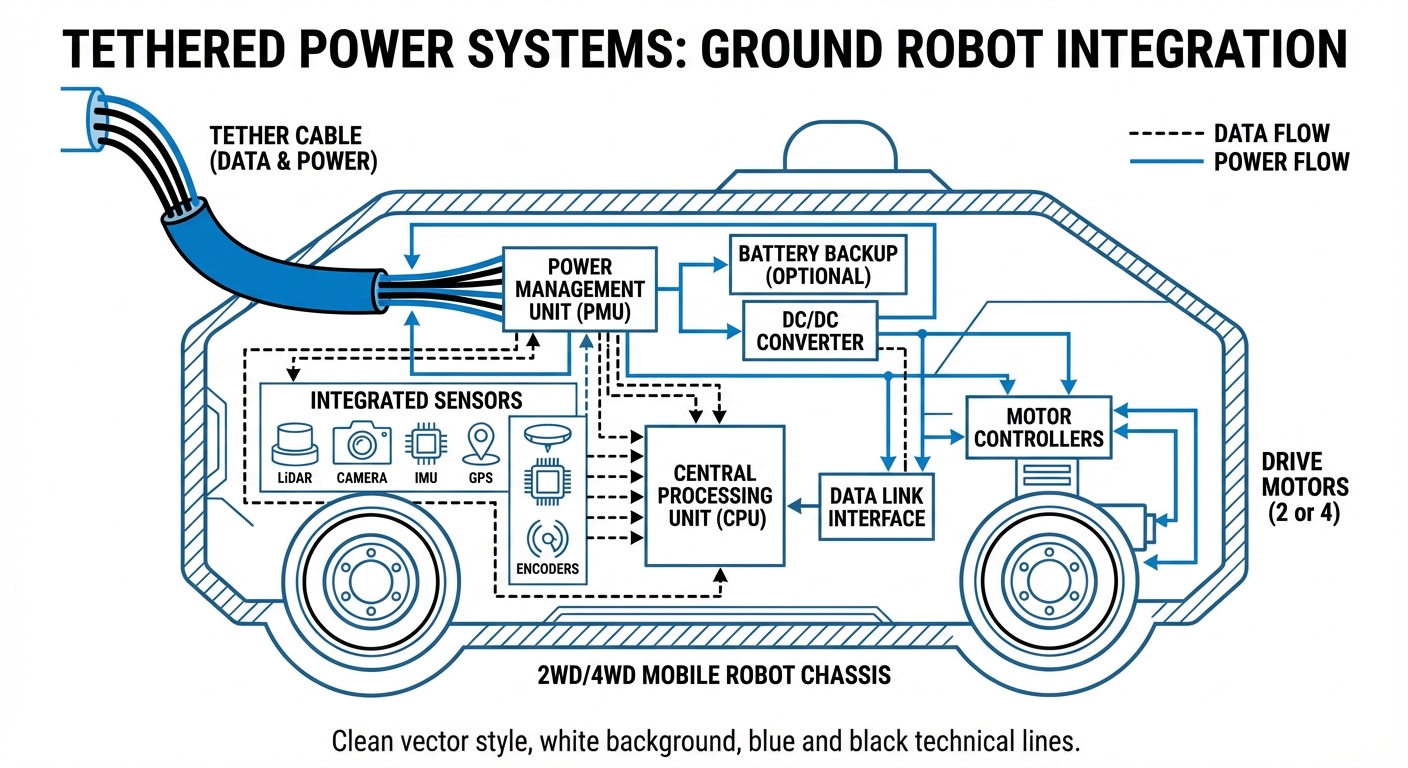

How It Works: The Umbilical Link

A Tethered Power System essentially extends the electrical grid directly to the mobile unit. The core component is the Tether Management System (TMS), which can be mounted on the robot or at a fixed base station. The TMS utilizes a motorized spool with active torque control to pay out and retract the cable as the robot moves, ensuring zero slack without impeding motion.

The cable itself—often referred to as an "umbilical"—is a composite engineering marvel. It typically contains high-gauge power conductors for driving motors, shielded twisted pairs for Ethernet communication, and sometimes fiber optic lines for noise-immune data transfer. Kevlar reinforcement is often added to withstand tensile stress.

At the connection point, high-voltage AC or DC is stepped down by onboard converters. This architecture removes the need for heavy chemical energy storage, replacing it with a constant flow of energy limited only by the length of the cable and the thermal capacity of the conductors.

Real-World Applications

Underwater ROVs

Remotely Operated Vehicles (ROVs) rely on tethers for deep-sea exploration. Radio waves do not penetrate water effectively, making tethers the only viable option for high-definition video feeds and powering heavy hydraulic arms at depth.

Nuclear Decommissioning

In high-radiation environments, complex battery electronics can fail rapidly due to ionization. Simple, shielded copper tethers provide robust power to demolition robots where wireless signals are unreliable and human entry is impossible.

Vertical Wall Climbers

For inspection robots climbing storage tanks or wind turbines, gravity is the enemy. Tethered systems remove the heavy battery weight, allowing magnetic or suction-based climbers to operate safely without risking detachment due to payload mass.

Warehouse Gantry Systems

While AMRs roam freely, high-speed shuttles in Automated Storage and Retrieval Systems (AS/RS) often use drag chains or flexible tethers to achieve extreme acceleration rates that would deplete batteries in minutes.

Frequently Asked Questions

What is the primary advantage of a tethered system over batteries?

The primary advantage is indefinite runtime. Unlike battery-powered robots that require hours of charging or swapping, tethered robots can operate continuously at peak performance. Additionally, they are significantly lighter, allowing for higher payloads or better agility.

How do you prevent the cable from getting tangled?

Tangling is mitigated through active Tether Management Systems (TMS). These use motorized reels with sensors to detect slack and tension, automatically retracting or paying out cable. Path planning algorithms also take the tether history into account to avoid "crossing the line."

What is the maximum effective range of a tethered robot?

Range is determined by cable weight and voltage drop. For small ground robots, 30-50 meters is common. For larger industrial applications using high-voltage transmission (to reduce current and cable thickness), ranges can extend to several hundred meters, though cable management becomes more complex.

Does the tether affect the robot's movement dynamics?

Yes, the tether introduces drag forces. The robot's control system must account for this variable force, which changes based on how much cable is deployed. Advanced controllers use force-feedback from the tether connection point to compensate for this drag in real-time.

Can data and power run through the same cable?

Absolutely. Modern umbilicals are composite cables containing shielded twisted pairs (for Ethernet) or fiber optics alongside power conductors. This enables gigabit-speed communication that is immune to RF interference, ideal for high-security or noisy industrial environments.

Are high-voltage tethers safe?

Safety is paramount. Tethers use thick, abrasion-resistant insulation (often PUR or Teflon). Systems typically include Ground Fault Circuit Interrupters (GFCI) and insulation monitoring devices that cut power in milliseconds if a breach or leakage current is detected.

What happens if the robot loses power (e.g., cable cut)?

Most tethered robots include a small backup battery or capacitor bank. This "buffer" provides just enough power to safely park the robot, save data, and shut down gracefully, preventing damage to actuators or loss of position data during a power failure.

Is a slip ring necessary?

If the cable reel rotates, a slip ring is required to maintain electrical continuity between the rotating spool and the stationary base. High-quality mercury or gold-contact slip rings are used to prevent signal noise in data lines during rotation.

Can tethered systems operate outdoors?

Yes, but the cable must be rated for the environment. Outdoor tethers require UV-resistant jackets and waterproofing. In muddy or rugged terrain, the drag increases significantly, so the tether management system must be more robust than in a clean warehouse floor.

How does the cost compare to battery systems?

Initial implementation costs can be higher due to the reel mechanism and infrastructure. However, operational costs (OPEX) are often lower because you eliminate expensive battery replacements (which degrade over time) and the logistics of charging management.

Can multiple tethered robots work in the same space?

This is challenging. Crossing tethers creates a high risk of entanglement. While possible with extremely strict path planning and layered cable heights (e.g., ceiling drops), tethered systems are generally best suited for single-robot zones or linear tracks.

What is a "Flying Tether"?

A flying tether usually refers to a drone (UAV) connected to a ground power station. This allows the drone to hover indefinitely for surveillance or lighting applications without the 20-30 minute battery flight time limit standard in commercial drones.

Ready to implement Tethered Power Systems in your fleet?

Discover how continuous power can revolutionize your automation workflow.

Explore Our Robots