Tactile Sensors

Give your autonomous mobile robots the ultimate safety fail-safe. Tactile sensors provide critical physical feedback, ensuring immediate stops upon contact and bridging the gap between perception and physical interaction in dynamic environments.

Core Concepts

Mechanical Bumpers

The most common AGV tactile sensor. These are physical switches usually placed on the chassis perimeter that trigger an emergency stop (E-stop) immediately upon compression.

Resistive Sensing

Utilizes conductive foam or ink layers. When pressure is applied, the electrical resistance drops, allowing the controller to detect the exact location and intensity of the impact.

Capacitive Skin

A "robotic skin" that detects proximity and light touch by measuring changes in capacitance. This allows for collision avoidance before hard contact actually occurs.

Safety Ratings (PL d)

Tactile sensors for industrial AGVs must typically meet Performance Level d (PL d) safety standards, ensuring reliability even if a component fails.

Force/Torque Sensors

Often used in mobile manipulators (robotic arms on AGVs), these measure the vector force applied to the end-effector to enable compliant handling of objects.

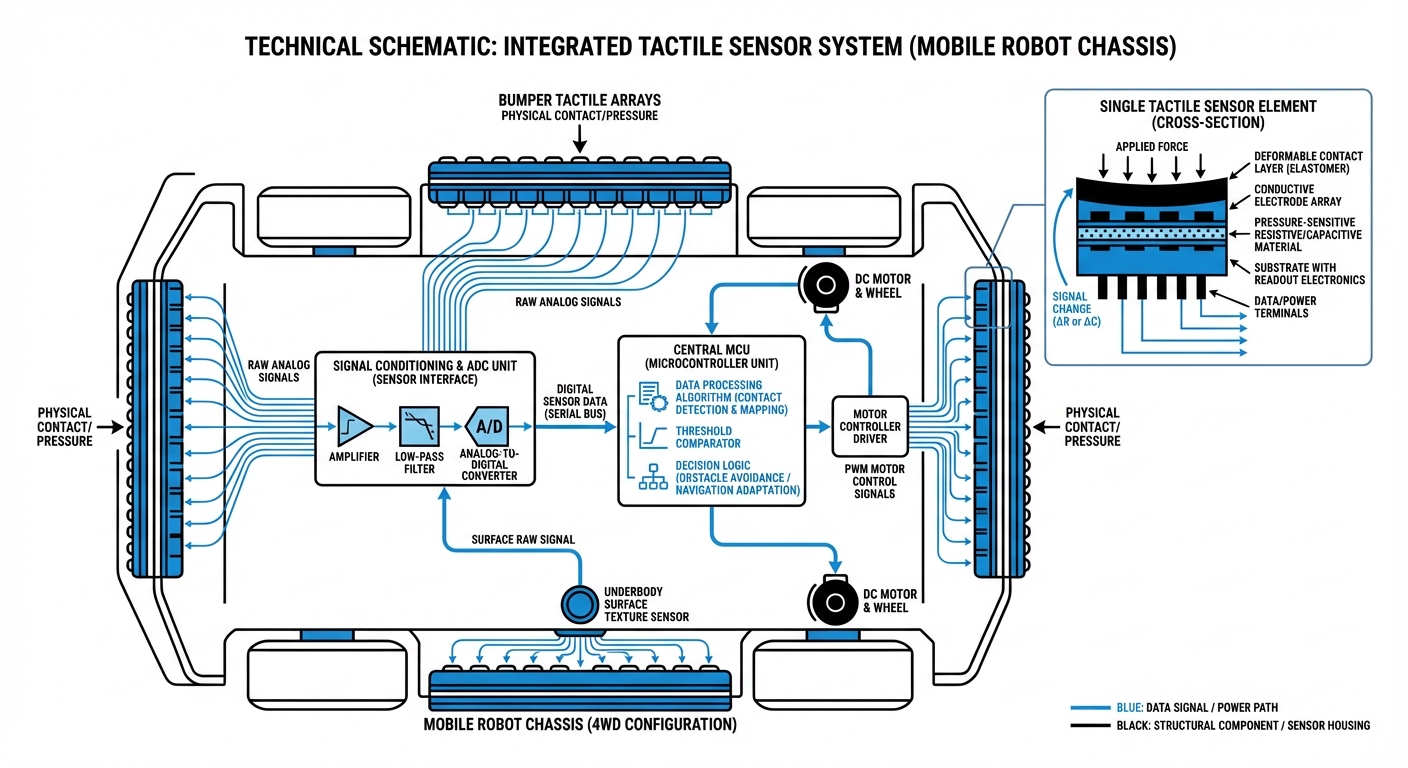

Signal Transduction

The process of converting physical deformation into an electrical signal. Speed is critical here to minimize stopping distance after a collision is detected.

How It Works

From Deformation to Decision

Tactile sensors function as the "nervous system" of the robot's outer shell. Unlike LiDAR or cameras which predict collisions, tactile sensors confirm them. When an external object presses against the sensor bumper or safety edge, internal conductive layers are compressed.

This compression closes an electrical circuit (or changes resistance), sending a high-priority interrupt signal directly to the robot's safety PLC. This bypasses high-level navigation logic to trigger a hardware-level braking sequence.

Modern systems utilize "Safety Edges"—flexible strips containing copper wires separated by non-conductive rubber. This design ensures that even a finger-pinch level of force triggers the stop mechanism, protecting human workers in collaborative spaces.

Real-World Applications

Warehousing & Logistics

High-speed AGVs utilize wrap-around tactile bumpers. If a forklift tine or dropped pallet enters the AGV's blind spot, the tactile sensor ensures the vehicle stops instantly upon contact to prevent chassis damage.

Healthcare & Hospitals

Delivery robots in hospital corridors navigate through dense crowds. Soft tactile skins allow these robots to gently "nudge" through crowds or stop if a patient unexpectedly steps into their path.

Heavy Manufacturing

For AGVs carrying multi-ton payloads, crushing hazards are a major risk. Pressure-sensitive safety mats and skirt sensors detect obstacles under the vehicle, preventing foot injuries.

Mobile Manipulation

AGVs equipped with robotic arms use fingertip tactile sensors to determine if the object they are picking up is rigid or fragile, adjusting grip strength automatically.

Frequently Asked Questions

Why do I need tactile sensors if my AGV already has LiDAR?

LiDAR is excellent for long-range detection, but it has blind spots, particularly very close to the floor or the robot's chassis. Tactile sensors act as a redundant, last-resort safety layer (ISO 13849-1 requirements) to handle "negative obstacles" or glass surfaces that LiDAR might miss.

What is the typical response time for a tactile bumper?

Response times are extremely fast, typically in the range of 5 to 15 milliseconds. This near-instantaneous signal transmission is crucial for minimizing the stopping distance once a collision has physically occurred.

How durable are safety edges in harsh environments?

Industrial safety edges are made from chemically resistant rubber (like EPDM or NBR) designed to withstand oil, coolants, and abrasion. Most are rated IP65 or IP67, making them dust-tight and resistant to water jets.

What happens if the wire to the sensor is cut?

Tactile sensors operate on a "fail-safe" principle. The system constantly monitors the circuit; if a wire is cut or the sensor is disconnected, the circuit opens, and the robot interprets this as a fault or collision, triggering an immediate stop.

Can tactile sensors detect the difference between a person and a wall?

Standard safety bumpers cannot distinguish materials; they are binary switches (on/off). However, advanced force-torque sensors or capacitive skins can analyze compliance (softness) to distinguish between a rigid wall and a human.

Do tactile sensors require regular calibration?

Mechanical bumpers and safety edges generally do not require software calibration. However, they require regular physical inspection to ensure the rubber hasn't hardened or cracked, which could impede the mechanical activation.

How much force is required to trigger a stop?

This is adjustable based on the sensor model but is typically very low for safety reasons. Standard ISO regulations often require activation forces below 150N for the body and significantly lower for fingers or hands.

Can I retrofit tactile sensors onto older AGVs?

Yes, retrofitting is common. Safety edges can be cut to length and mounted to the chassis with aluminum rails. The wiring is then integrated into the existing E-stop circuit of the AGV.

Do they work in freezing temperatures (Cold Storage)?

Standard rubber hardens in freezing temperatures, which can cause sensor failure. For cold storage AGVs, you must specify sensors made with silicone or specialized low-temperature rubber compounds.

What is the "overtravel" distance?

Overtravel is the distance the bumper compresses after the signal is sent but before the robot physically stops. The bumper must be thick enough to absorb the robot's kinetic energy during this braking distance to prevent injury.

Are there wireless tactile sensors for rotating parts?

Yes, wireless signal transmission systems exist for safety edges mounted on rotating turrets or doors where cabling is impossible. These must meet high reliability standards to ensure the signal is not lost due to interference.

How does dust affect tactile sensors?

Unlike optical sensors (LiDAR/Cameras) which are easily blinded by dust, tactile sensors are mechanical and largely immune to airborne particulates. This makes them ideal for sawmills, textile plants, and dusty warehouses.