Swerve Drive Modules

Unlock true omnidirectional agility for autonomous mobile robots (AMRs). By decoupling steering and traction, swerve drive modules allow AGVs to translate in any direction and rotate instantaneously, revolutionizing efficiency in complex environments.

Core Concepts

Holonomic Motion

Achieve freedom of movement in X, Y, and Theta axes simultaneously. The robot can strafe sideways or move diagonally without rotating the chassis.

Independent Control

Each module contains its own steering and drive motors. This independence allows for complex maneuvers impossible with differential drive systems.

High Traction

Unlike mecanum wheels which rely on rollers, swerve modules use standard traction tires, providing superior grip on floors and handling higher payloads.

Integrated Encoders

Built-in absolute encoders ensure precise wheel alignment and odometry, allowing for highly accurate path following and docking procedures.

Zero Radius Turn

By orienting all wheels tangentially to a center point, the robot can rotate in place (turn on a dime), ideal for navigating narrow aisles.

Slip Ring Technology

Advanced coaxial swerve modules utilize slip rings to allow infinite continuous rotation of the steering axis without twisting internal wires.

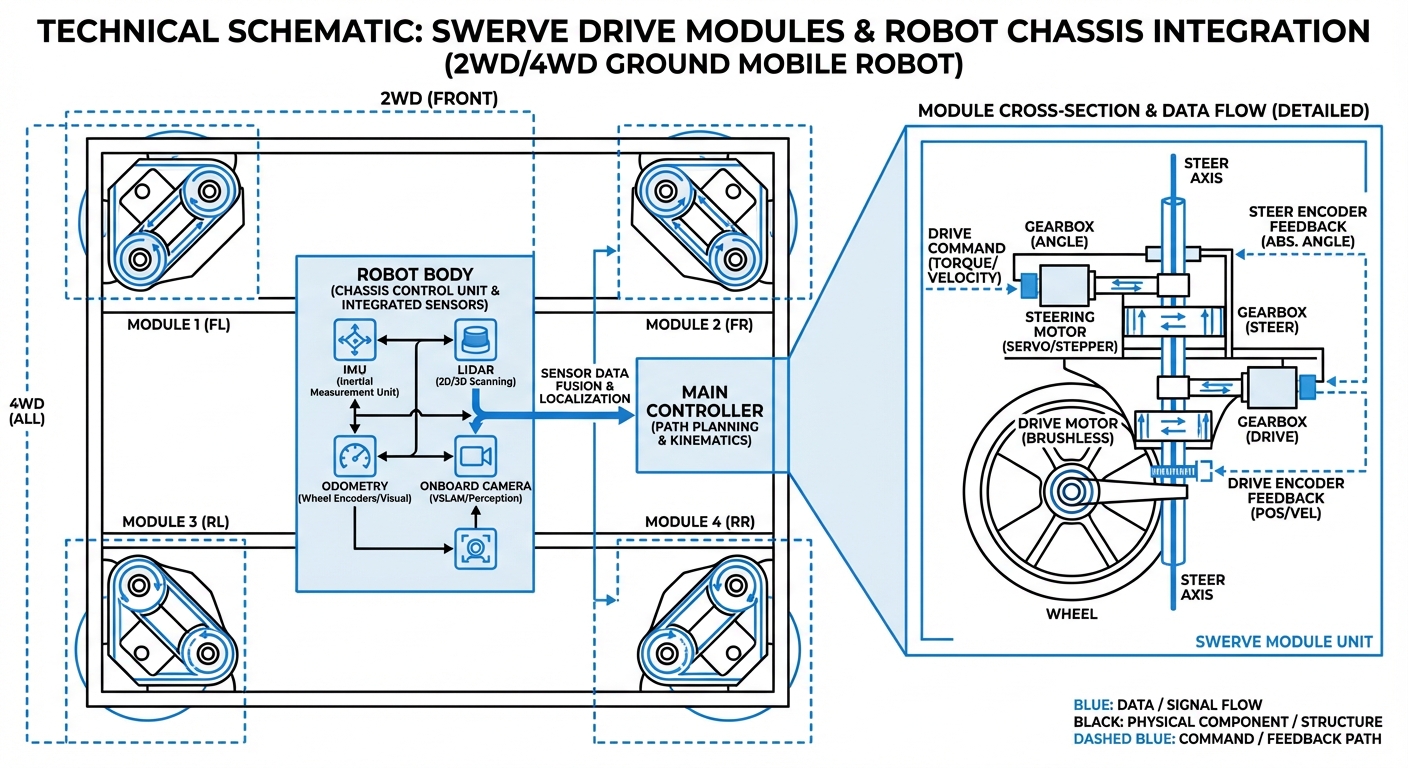

Anatomy of a Swerve Module

A swerve drive module acts as an independent "robot leg." It fundamentally changes how we approach robot chassis design by compacting propulsion and steering into a single unit.

The Mechanism: Two motors operate in tandem. The Steering Motor rotates the entire wheel assembly around the vertical Z-axis. The Drive Motor powers the wheel rotation for forward or backward movement. In a Coaxial setup, the drive motor is mounted statically above the wheel, transmitting power through a central shaft and bevel gears.

The Result: The control system calculates the necessary vector (speed and angle) for each of the four modules independently. This inverse kinematics calculation allows the robot chassis to translate in one direction while simultaneously rotating to face another.

- ✓ Standard: 4-Wheel independent swerve configuration.

- ✓ Payload: High load capacity due to direct wheel contact.

- ✓ Efficiency: Less energy loss compared to mecanum roller friction.

Real-World Applications

High-Density Warehousing

AGVs equipped with swerve drives can enter narrow aisles and move sideways to pick pallets, reducing the required aisle width by up to 30% compared to Ackerman-steered vehicles.

Automotive Manufacturing

Moving massive sub-assemblies like chassis or fuselage sections requires precise mating. Swerve drives allow for micro-adjustments in position without needing to back up and realign.

Medical Transport

In crowded hospital corridors, transport robots must dodge personnel and equipment. The ability to strafe instantly prevents collisions and improves safety in dynamic environments.

Flexible Assembly Lines

Replacing fixed conveyor belts with swarm AGVs. Swerve modules allow the layout of the factory floor to change dynamically based on production needs without infrastructure overhaul.

Frequently Asked Questions

What is the main advantage of Swerve Drive over Differential Drive?

The primary advantage is holonomic motion. While differential drive robots must rotate to change direction, swerve drive robots can move instantly in any direction (strafe) while independently controlling their heading. This makes them significantly more agile in confined spaces.

How does Swerve Drive compare to Mecanum wheels?

Both offer omnidirectional movement, but Swerve Drive offers superior traction and load capacity. Mecanum wheels lose roughly 30% of their force to vector cancellation and rely on rollers that can slip or wear unevenly. Swerve modules use standard tires, making them better for uneven floors, ramps, and heavy industrial loads.

Are Swerve Drive modules difficult to control?

They require more complex software than basic drives due to the Inverse Kinematics calculations needed to coordinate four independent modules. However, modern motion control libraries and ROS (Robot Operating System) packages have standardized these calculations, making implementation much more accessible.

What is a "Coaxial" Swerve Module?

In a coaxial design, the drive motor is mounted centrally above the steering axis, and power is transmitted to the wheel via a shaft running through the center of the steering gear. This keeps the motors static and protected inside the chassis, reducing the rotating mass and allowing for continuous 360-degree rotation.

Can Swerve Drive AGVs handle ramps or inclines?

Yes, much better than mecanum robots. Because the wheels always align with the direction of travel and use high-friction tire material (like polyurethane or rubber), they maintain full traction on inclines, provided the center of gravity remains stable.

What maintenance is required for these modules?

Routine maintenance includes checking the bevel gears for lubrication, inspecting the tread wear on the wheels, and ensuring the absolute encoders retain their zero-offset calibration. Since they have more moving parts than a simple hub motor, periodic inspection of the steering bearings is recommended.

Why are absolute encoders necessary?

Absolute encoders tell the robot exactly where the wheel is pointing immediately upon startup, without needing to perform a homing sequence. This is critical for safety and instant operation, ensuring the wheels don't align randomly when the robot is powered on.

Does Swerve Drive consume more power?

A 4-module swerve robot uses 8 motors (4 drive, 4 steer), compared to 2 or 4 in other systems. While this increases the peak potential power draw, the efficiency of movement (taking direct paths without backing up) often results in comparable or better net energy usage per task.

What is the typical payload capacity?

This varies by module size. Small robotic modules handle 50-100 lbs per wheel, while heavy-duty industrial swerve units can support several tons per module, enabling AGVs to move aircraft parts or heavy machinery.

How does scrub radius affect performance?

A non-zero scrub radius (offset between the steering axis and the center of the wheel patch) creates friction when steering while stopped. Designers minimize this to reduce steering motor load, although a small amount of scrub can provide better feedback for wheel orientation.

Are slip rings required for all swerve modules?

Not strictly required, but highly recommended for industrial applications. Without slip rings, the module is limited in how many times it can rotate before wires twist and snap. Slip rings enable true infinite rotation, simplifying path planning software.

Is Swerve Drive cost-effective?

Swerve modules have a higher initial hardware cost due to the number of motors and gearboxes. However, for applications requiring complex maneuvering in expensive real estate (like high-density warehouses), the ROI is achieved through increased throughput and space optimization.