Supercapacitors

Revolutionize your AGV fleet's uptime with energy storage solutions designed for rapid "opportunity charging" and extreme durability. Supercapacitors bridge the gap between traditional capacitors and rechargeable batteries, delivering high power density for demanding industrial robotics.

Core Concepts

High Power Density

Unlike batteries which excel at energy density, supercapacitors offer immense power density, allowing them to release energy in massive bursts for high-torque AGV lifting operations.

Flash Charging

Charge an entire robotic unit in seconds rather than hours. This enables "opportunity charging" where robots top up energy during brief stops at loading docks.

Extreme Cycle Life

With the ability to withstand over 1 million charge-discharge cycles, supercapacitors outlast Li-Ion batteries by a factor of 100, virtually eliminating replacement costs.

Enhanced Safety

Supercapacitors rely on electrostatic storage rather than volatile chemical reactions, drastically reducing the risk of thermal runaway and fire in warehouse environments.

Wide Temp Range

Operational efficiency remains stable from -40°C to +65°C, making them the ideal choice for cold-storage logistics and high-heat industrial foundries.

Maintenance Free

Designed as a "fit and forget" component. Without the degradation caused by chemical changes, maintenance requirements for the power unit are effectively zero.

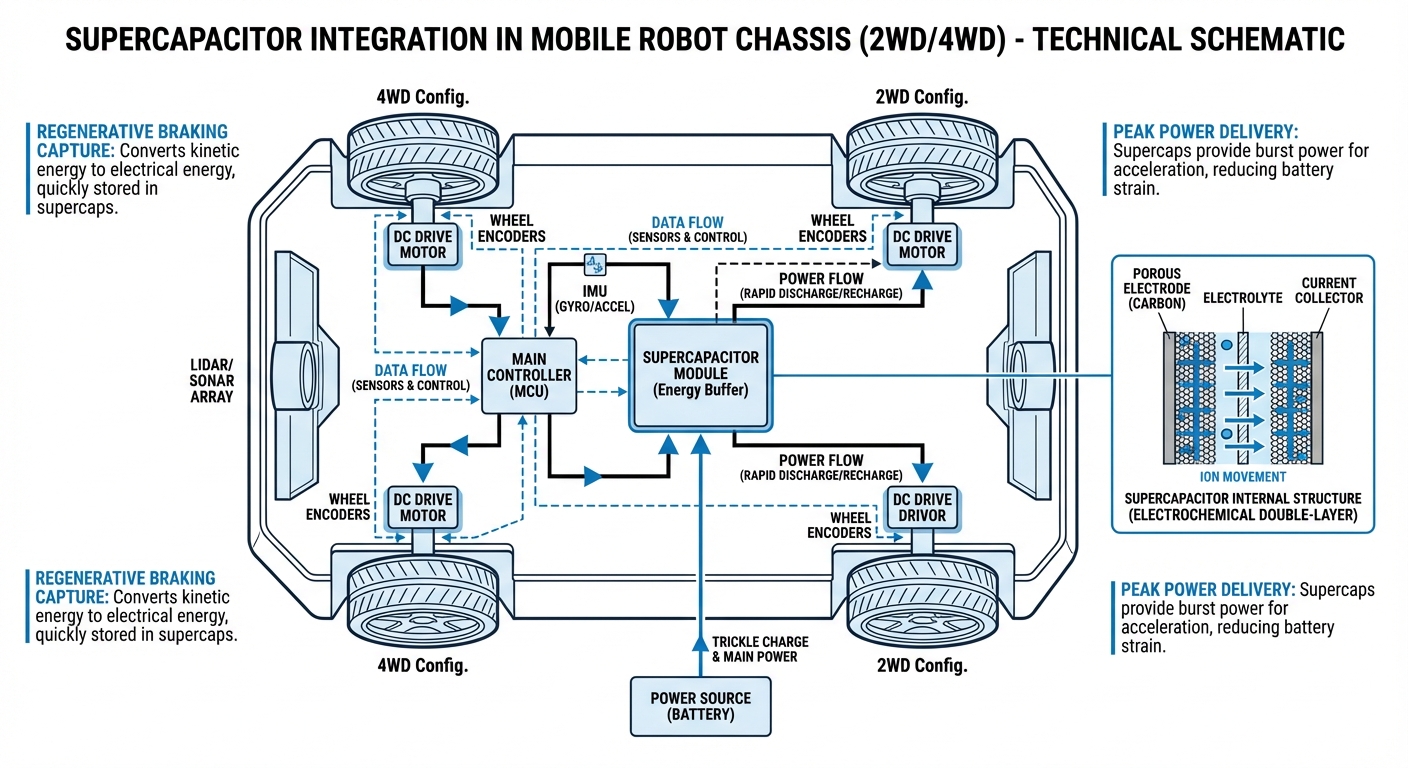

How It Works: Electrostatic Storage

Unlike traditional batteries that rely on slow chemical reactions to store and release energy, supercapacitors (or ultracapacitors) store energy electrostatically via the Double-Layer effect (EDLC). Positive and negative charges accumulate on the surface of porous carbon electrodes, separated by an electrolyte.

This physical mechanism allows for near-instantaneous charging and discharging. In an AGV context, this means the robot does not need to be removed from the workflow for hours to charge. Instead, it interacts with a charging plate for 10-30 seconds, absorbing enough energy for its next task loop.

For maximum efficiency, modern robotics often employ a Hybrid System: utilizing supercapacitors for peak power demands (lifting, acceleration) and batteries for sustained energy cruising, optimizing the lifespan of both components.

Real-World Applications

24/7 Warehouse Logistics

In high-throughput fulfillment centers, AGVs cannot afford downtime. Supercapacitors allow robots to charge while loading a pallet, ensuring continuous operation without spare vehicles or battery swapping rooms.

Cold Chain Automation

Lithium-ion batteries suffer significant capacity loss in freezing temperatures. Supercapacitor-powered AGVs thrive in sub-zero freezers, maintaining full power capability in food storage and pharmaceutical cold chains.

Heavy Payload Lifting

Robots requiring massive bursts of current to lift heavy chassis or manufacturing components use supercapacitors to provide the peak amperage that would otherwise damage standard battery cells.

Automated Guided Trams

For fixed-path industrial shuttles, supercapacitors allow the vehicle to run without overhead lines, charging rapidly at each station stop (flash charging) before moving to the next assembly point.

Frequently Asked Questions

What is the main difference between a supercapacitor and a Li-Ion battery?

The primary difference is Power Density vs. Energy Density. Batteries store more total energy (run time) but charge/discharge slowly. Supercapacitors store less total energy but can charge and release it almost instantly, making them ideal for high-power bursts and rapid cycling.

Can a supercapacitor replace the battery in my AGV entirely?

Yes, for specific applications. If your AGV operates on a fixed loop with frequent stops (every few minutes) where charging contacts are installed, a supercapacitor is superior due to fast charging. For free-roaming AMRs requiring hours of autonomy, a hybrid or battery-only system is preferred.

How long does it take to charge a supercapacitor-based robot?

Charging times are typically measured in seconds. A typical industrial AGV can recharge enough energy for its next cycle in 10 to 60 seconds, allowing for "in-process" charging while the robot is loading or unloading material.

What is the expected lifespan of a supercapacitor?

Supercapacitors are incredibly durable, often rated for 1,000,000+ charge-discharge cycles. In a 24/7 industrial environment, this translates to 10-15 years of operation without replacement, compared to 2-3 years for lead-acid or Li-Ion batteries.

Do supercapacitors have a self-discharge issue?

Yes, supercapacitors have a higher self-discharge rate than batteries. If a robot is left turned off for several days, the capacitor may drain completely. However, because they can recharge in seconds upon startup, this is rarely an operational issue in active fleets.

Are special electronics required to use supercapacitors?

Yes. Unlike batteries which maintain a relatively flat voltage curve, a supercapacitor's voltage drops linearly as it discharges. A DC-DC converter is required to stabilize the output voltage for the robot's motors and sensors.

How does temperature affect performance?

Supercapacitors are far more thermally stable than batteries. They operate efficiently between -40°C and +65°C. This makes them the only viable option for unheated warehouses in winter or cold storage applications where batteries would become sluggish or fail.

Is it expensive to implement supercapacitor technology?

The upfront cost per kWh is higher than batteries. However, when calculating Total Cost of Ownership (TCO), supercapacitors are often cheaper because they do not require replacement, maintenance, or expensive battery swapping infrastructure over the robot's lifetime.

What is a "Hybrid Configuration"?

A hybrid configuration connects a battery and a supercapacitor in parallel. The supercapacitor handles high-current peaks (acceleration, lifting), protecting the battery from stress, while the battery provides long-term energy density. This extends the battery life significantly.

Are supercapacitors safe for indoor use?

Extremely safe. They do not contain heavy metals or volatile organic solvents typical of batteries. They can be shipped fully discharged (0V) with no risk, and they do not suffer from thermal runaway, significantly lowering fire risks in factories.

How do I size a supercapacitor for my robot?

Sizing is based on the peak power required and the duration of that peak, rather than total run time. You calculate the energy (Joules) needed for the specific movement (e.g., lifting a 1-ton load) plus a safety margin, rather than Amp-hours needed for a shift.

Can existing robots be retrofitted with supercapacitors?

Yes, retrofitting is possible, especially for lead-acid battery replacement. However, it requires integrating a power management system (PMS) to handle the voltage variance and ensure the charging infrastructure provides the high current needed for fast charging.