Stepper Motors

Precision meets reliability. Stepper motors are the foundational drive technology for modern AGVs, converting digital pulses into exact mechanical motion to ensure accurate navigation without complex feedback loops.

Core Concepts

Step Angle

The minimum degree of rotation associated with a single digital pulse. Common angles like 1.8° allow for 200 distinct steps per revolution, enabling high-resolution positioning.

Holding Torque

Ideally suited for robotics, stepper motors generate maximum torque at standstill. This acts as a dynamic brake, holding the AGV in place on inclines without mechanical brakes.

Open-Loop Control

Unlike servos, steppers do not require encoders for operation. The controller assumes the motor moves to the commanded position, simplifying circuit design and reducing cost.

Microstepping

By varying the current ratio between coils, drivers can divide steps into smaller "microsteps" (up to 256x). This eliminates vibration and results in silky-smooth AGV movement.

Detent Torque

The magnetic resistance felt when turning the motor shaft by hand when unpowered. High detent torque can be useful for safety in vertical lift applications during power loss.

Speed vs. Torque

Steppers trade speed for torque. They possess massive low-speed torque but lose power at high RPMs, making them perfect for heavy-load, slow-moving warehouse robots.

How It Works

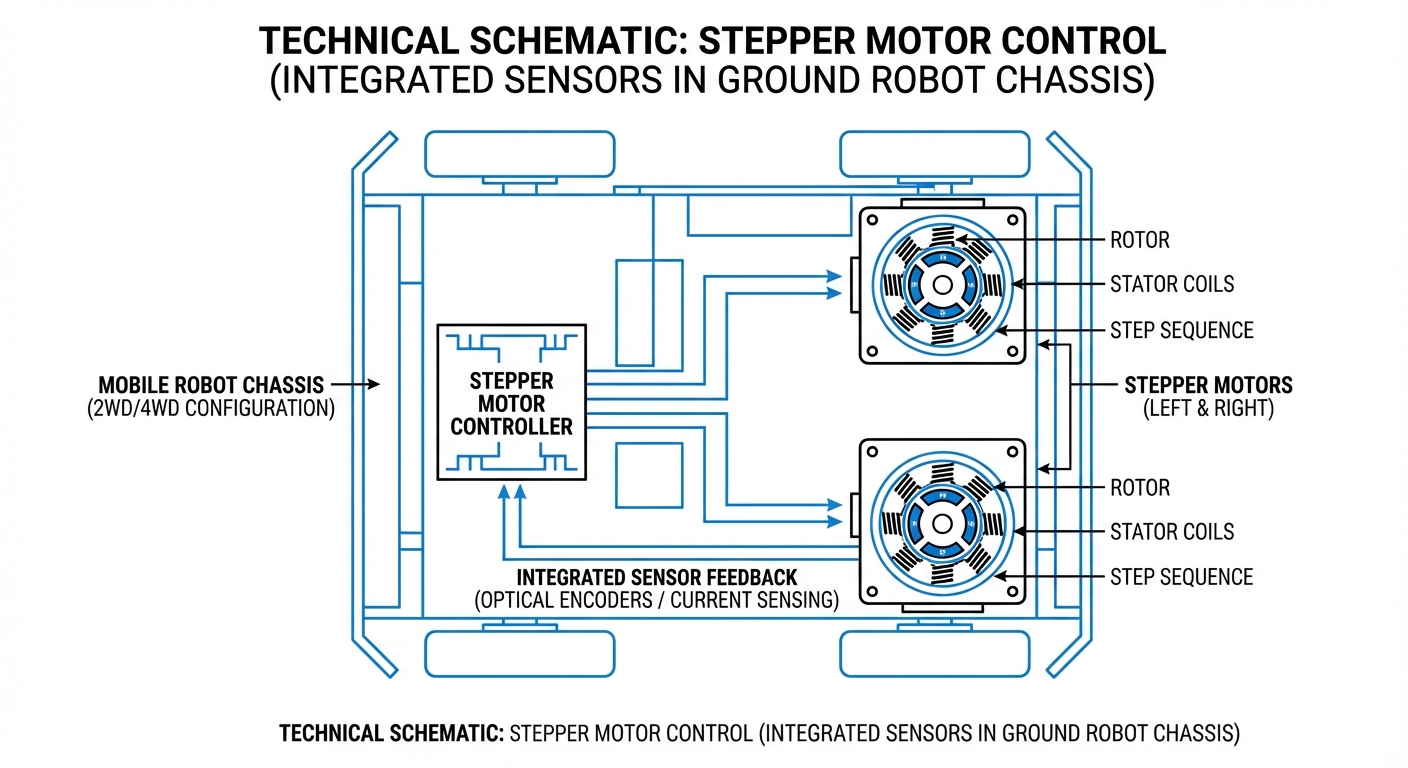

At the heart of a stepper motor is a rotor typically made of permanent magnets, surrounded by a stator housing multiple electromagnetic coils. The magic lies in the sequence of energization.

When a specific coil phase is energized, it creates a magnetic field that aligns the rotor's teeth with the stator's teeth. By switching the power to the next coil in the sequence, the rotor is pulled into the next position.

For AGVs, this digital nature allows the navigation computer to calculate exactly how far the robot has traveled by simply counting the pulses sent to the wheels. 1,000 pulses equals a specific distance, eliminating cumulative errors found in DC motor drift.

Real-World Applications

Differential Drive AGVs

The most common use case. Two stepper motors control two main wheels independently. By varying the pulse frequency to each motor, the robot can turn on a dime or move in a perfectly straight line across warehouse floors.

Vertical Lift Modules

Used in autonomous forklifts and inventory retrieval robots. The high holding torque ensures that the lifting platform stays locked in position at the exact shelf height while loading or unloading goods.

On-Board Conveyors

Many mobile robots feature small conveyor belts on top to transfer totes. Stepper motors provide the start-stop precision required to align the on-board belt perfectly with static factory conveyors.

LIDAR Sensor Rotation

For SLAM navigation, LIDAR sensors must spin at a constant rate. Small, precision steppers ensure the sensor head rotates smoothly, providing consistent mapping data without jitter.

Frequently Asked Questions

Stepper Motors vs. Servo Motors: Which is better for AGVs?

It depends on the application. Steppers are cost-effective, offer excellent low-speed torque, and are easier to control for stable loads. Servos are better for high-speed, dynamic loads where efficiency and feedback are critical. For standard warehouse AGVs moving at moderate speeds, steppers are often the superior value choice.

What causes "missed steps" and how do I prevent it?

Missed steps occur when the load torque exceeds the motor's pull-out torque, causing the rotor to lag behind the magnetic field. This is usually caused by accelerating too quickly or hitting an obstacle. To prevent this, implement S-curve acceleration ramps in your code and ensure the motor is sized with a 30-50% torque safety margin.

Why do stepper motors get hot even when the robot is stopped?

Unlike DC motors, steppers draw full current at standstill to maintain holding torque. This constant current generates heat. To mitigate this, use "current reduction" or "standby" features in your driver, which lower the current (e.g., to 50%) when the motor is idle for more than a few milliseconds.

Do I need a gearbox for my stepper motor?

Often, yes. While steppers have high torque, direct-driving wheels can be inefficient for heavier robots. A planetary gearbox increases torque output and resolution while dampening vibration. A 5:1 or 10:1 ratio is common for mobile robots to balance speed and towing capacity.

What is the difference between Bipolar and Unipolar wiring?

Bipolar motors (4 wires) use the full coil winding, offering significantly higher torque (about 30-40% more) than Unipolar motors (5, 6, or 8 wires). Bipolar requires a more complex H-bridge driver, but it is the industry standard for modern robotics due to the torque efficiency.

How does microstepping affect positioning accuracy?

Microstepping is primarily for smoothness and resonance reduction, not necessarily accuracy. While 1/16 microstepping increases the theoretical resolution, the incremental torque between microsteps is small. Friction can prevent the motor from achieving the exact micro-position. Rely on full steps for guaranteed accuracy.

What NEMA size should I use for a warehouse AGV?

For light loads (under 10kg), NEMA 17 is sufficient. For medium warehouse robots (up to 50kg), NEMA 23 is the standard workhorse. For heavy industrial pallet movers, NEMA 34 or NEMA 42 motors are required to generate the necessary torque to overcome inertia and rolling resistance.

Can I run a stepper motor in a closed-loop configuration?

Yes. "Closed-loop steppers" or "hybrid steppers" include an encoder on the back of the motor. The driver compares the commanded steps to the actual position. If the motor stalls or misses steps, the driver compensates immediately. This offers the best of both worlds: stepper torque with servo reliability.

How does voltage affect stepper motor performance?

Higher voltage allows the current to rise faster in the coils, which improves high-speed performance. If your AGV needs to move quickly, running a 3.5V rated motor at 24V or 48V (with a chopper driver) is essential to maintain torque at speed.

Are stepper motors waterproof?

Standard steppers are open and not waterproof (IP40). For AGVs operating in washdown areas or outdoors, you must purchase IP65 or IP67 rated stepper motors which feature sealed housings, waterproof connectors, and specialized shaft seals to prevent corrosion.

What is resonance and why is my robot vibrating?

Every stepper has a natural resonant frequency. Operating at this specific speed causes excessive vibration and noise, potentially leading to stalling. To fix this, avoid the resonant speed range in your software, increase microstepping, or add a mechanical damper to the motor shaft.

How do I calculate the battery life of an AGV using steppers?

Calculate the total current draw of all motors (Amps per phase × 2 phases). Since steppers draw current continuously, multiply this by your operating voltage to get Wattage, then divide your battery capacity (Wh) by the total Wattage. Remember that steppers are less efficient than DC motors, so battery sizing is critical.