Soft Robotics Materials

Discover the revolutionary shift from rigid links to compliant, flexible materials that enable AGVs to handle delicate payloads, navigate unpredictable environments safely, and collaborate seamlessly with human operators.

Core Concepts

Elastomers & Silicones

The foundation of soft robotics, these highly stretchable polymers allow grippers and bumpers to deform significantly without permanent damage, ensuring safe contact.

Shape Memory Alloys

Metals that "remember" a specific shape and return to it when heated. Used in compact actuators for AGV mechanisms requiring high force-to-weight ratios.

Electroactive Polymers

Often called "artificial muscles," EAPs change size or shape when stimulated by an electric field, providing silent and energy-efficient actuation for mobile robots.

Variable Stiffness

Materials that can switch between soft and rigid states (e.g., via jamming transition), allowing an AGV to squeeze through gaps yet carry heavy loads.

Pneumatic Networks

Channels embedded within soft materials that inflate to create motion. This fluidic logic enables complex bending and twisting for adaptable robotic limbs.

Self-Healing Materials

Advanced polymers capable of repairing micro-cracks and cuts autonomously, significantly extending the lifespan of AGV bumpers and soft skins.

How Soft Materials Function

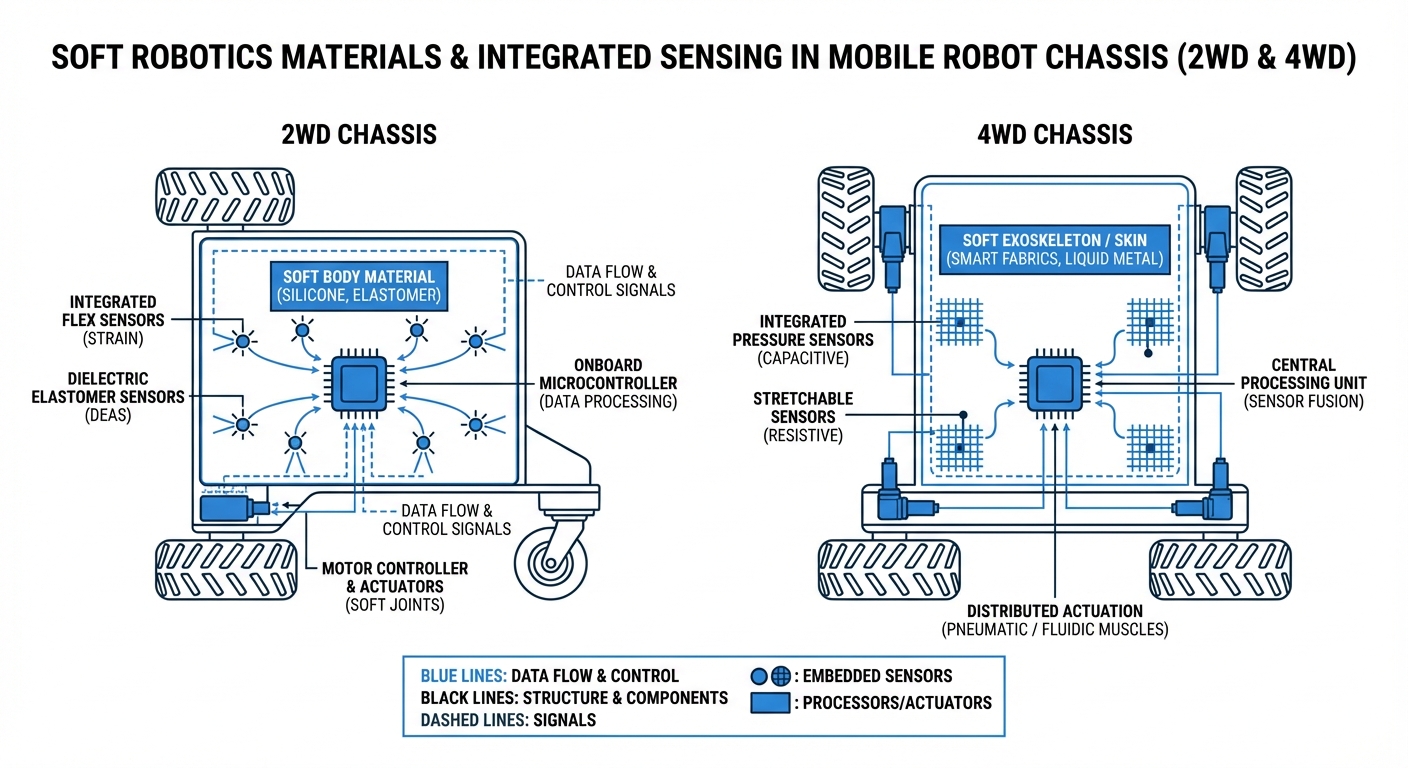

Unlike traditional robotics that rely on rigid kinematics and precise joint angles, soft robotics materials leverage material compliance to function. This means the material itself acts as the joint, the sensor, and sometimes the actuator.

In an AGV context, this is typically achieved through Continuum Deformation. Instead of rotating a gear, we inflate a silicone chamber or apply voltage to a polymer sheet. This creates a distributed force, allowing a gripper to wrap around a weirdly shaped package, or a wheel to deform over an obstacle rather than bouncing off it.

The control systems for these materials rely on modeling non-linear elasticity. By calculating how the material stretches, the robot can predict its position without rigid encoders, often using embedded conductive sensors that stretch with the "skin" of the robot.

Real-World Applications

Fragile Inventory Handling

Soft grippers on AMRs allow for the automated picking of groceries, electronics, and glassware. The compliance of the material prevents crushing, enabling high-speed handling of items with varying geometries.

Collaborative Safety Skins

AGVs wrapped in soft, sensor-embedded skins can detect collisions instantly. Unlike hard bumpers, the soft material absorbs the impact energy, allowing robots to work closer to humans without safety fences.

Adaptive Locomotion

Soft, deformable wheels or tracks allow outdoor delivery robots to navigate curbs, gravel, and uneven terrain by molding their shape to the ground, maximizing traction and reducing vibration.

Food & Hygiene Processing

Monolithic soft silicone grippers are easy to sanitize and lack the crevices of mechanical claws. This makes them ideal for AGVs operating in clean rooms or food processing lines handling raw ingredients.

Frequently Asked Questions

What is the primary advantage of soft materials over rigid metal components?

The primary advantage is "compliance," or the ability to yield to external forces. This makes soft robots inherently safer for human interaction, more adaptable to unstructured environments, and capable of handling delicate or irregularly shaped objects without complex sensing algorithms.

Are soft robotics materials durable enough for industrial AGV use?

Yes, modern industrial elastomers and composites are designed for millions of cycles. While they may not have the impact resistance of steel, materials like self-healing polymers and reinforced silicones offer excellent fatigue resistance and can withstand abrasive warehouse environments.

How do soft grippers handle heavy payloads?

Soft grippers typically rely on friction and "form closure" (wrapping around the object) rather than crushing force. For heavier loads, variable stiffness techniques (like jamming) are used to make the soft gripper rigid once it has grasped the object, locking it in place.

Do soft materials require different control systems?

Yes, controlling soft materials involves dealing with non-linear dynamics (infinite degrees of freedom). Standard rigid-body physics engines often struggle, so engineers use finite element analysis (FEA) or machine learning models to predict how the material will deform under pressure.

What is the power source for soft actuators?

The most common power source is compressed air (pneumatics) due to its speed and force density. However, electrically actuated materials like Dielectric Elastomer Actuators (DEAs) are gaining popularity because they eliminate the need for bulky pumps and compressors on mobile robots.

Can soft materials be used for AGV wheels?

Absolutely. Deformable wheels made of soft lattice structures or air-filled cavities provide built-in suspension. This allows AGVs to traverse small obstacles, cables, and floor imperfections without transmitting vibration to sensitive payloads.

How does temperature affect soft robotics materials?

Standard silicones perform well across a wide temperature range, but Shape Memory Alloys (SMAs) are specifically triggered by heat. Extreme cold can make some elastomers brittle, so material selection must match the operating environment (e.g., cold storage warehouses).

Are soft robotics safer for human collaboration?

Yes, this is one of their biggest selling points. The low inertia and inherent softness of the materials mean that an accidental impact transmits very little energy, significantly reducing the risk of injury compared to rigid metal arms.

Is it expensive to implement soft materials?

The materials themselves (silicones, plastics) are often cheaper than precision-machined metals. However, the R&D for custom molds and the integration of specialized pneumatic control systems can increase initial implementation costs.

Can we retrofit existing AGVs with soft components?

Yes, the most common retrofit is swapping out a standard rigid gripper for a soft gripper end-effector. Adding soft bumpers or skins is also a feasible upgrade to improve the safety rating of existing mobile robot fleets.

What happens if a soft robot gets punctured?

For pneumatic systems, a puncture results in loss of function. However, "self-healing" polymers are being developed that can seal cuts chemically. Additionally, many soft designs use redundant chambers, so the robot can continue working even if one section is damaged.

What is the future of soft materials in logistics?

The future lies in "hybrid" robots that combine the strength of rigid skeletons with the adaptability of soft muscles, as well as fully biodegradable soft robots. We also expect to see "smart skins" where sensors are printed directly onto the soft material for full-body perception.