Series Elastic Actuators

Revolutionize mobile robotics with compliant actuation technology. Series Elastic Actuators (SEAs) introduce a calibrated spring element between the motor and load, delivering superior force control, shock tolerance, and safety for next-generation AGVs.

Core Concepts

Mechanical Compliance

Unlike rigid actuators, SEAs deliberately introduce elasticity. This "give" allows the robot to adapt mechanically to external forces before the control loop even engages.

Force Fidelity

By measuring the deflection of the spring element, torque can be calculated with high precision according to Hooke’s Law, often eliminating the need for expensive torque sensors.

Shock Tolerance

The elastic element acts as a low-pass filter for shock loads, protecting the gearbox and motor from damage during collisions or when traversing uneven terrain.

Energy Storage

SEAs can store and release potential energy cyclically. This passive energy storage improves efficiency in repetitive tasks or oscillatory movements in mobile platforms.

HRI Safety

In Human-Robot Interaction (HRI), the inherent low impedance of the actuator reduces impact forces significantly, making AGVs safer to operate alongside human workers.

Contact Stability

SEAs provide stable force control even when making contact with stiff environments (like docking stations or heavy pallets), preventing the "chattering" seen in stiff position-controlled robots.

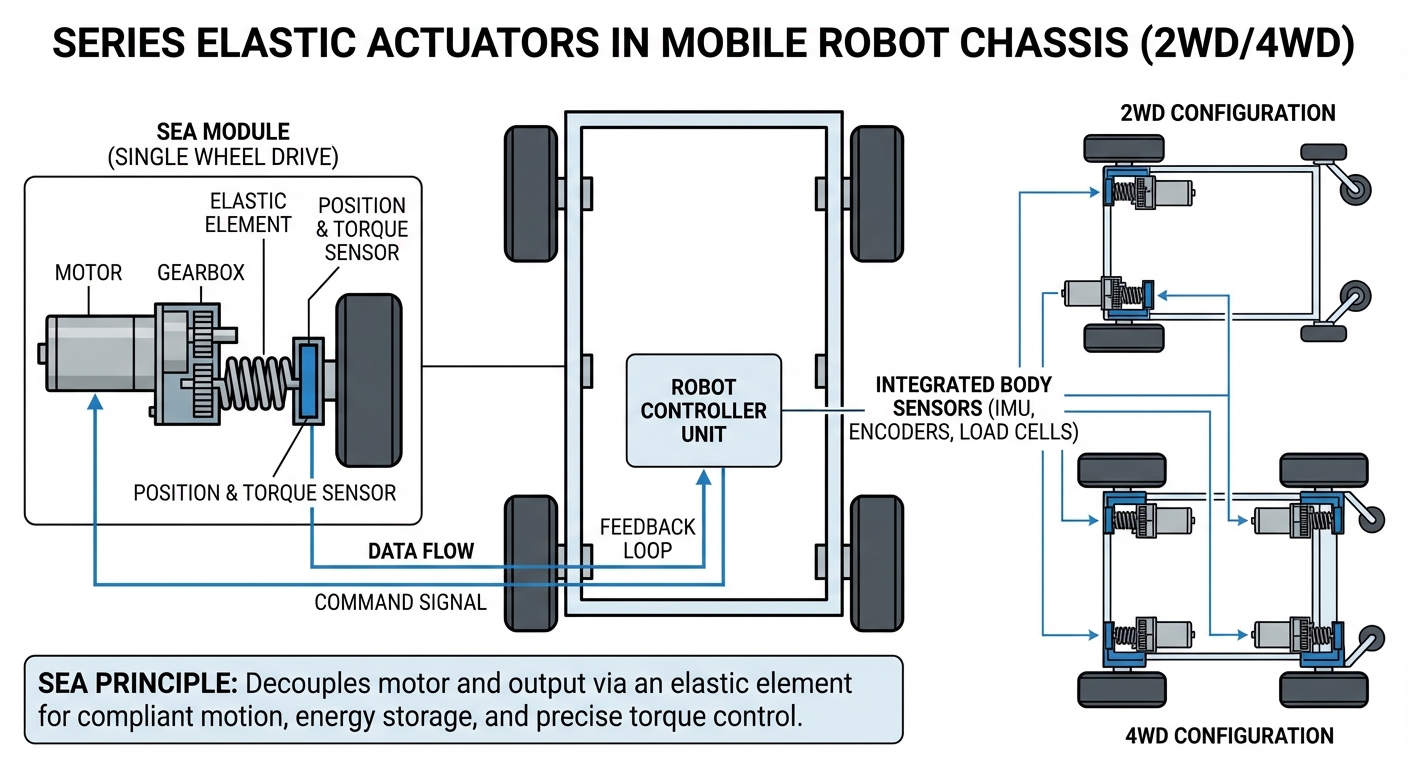

How It Works: The Architecture

In a traditional "stiff" actuator, the motor connects directly to the gearbox and the load. In a Series Elastic Actuator, a compliant element—typically a customized spring or flexure—is placed in series between the gear train and the output load.

The control system measures the deflection of this spring ($x$) using high-resolution encoders. Because the stiffness of the spring ($k$) is known constant, the force ($F$) exerted on the load can be calculated instantly using Hooke's Law: $F = k \cdot x$.

This architecture turns force control into a position control problem for the motor. By controlling the compression of the spring, the AGV can precisely regulate the torque applied to its wheels or lifting mechanism, effectively decoupling the motor's inertia from the load's inertia.

Real-World Applications

Collaborative Warehousing

AGVs equipped with SEAs can operate safely in high-traffic aisles. If a collision occurs, the actuator absorbs the energy, preventing injury to personnel and damage to inventory, allowing for fence-free automation.

Rough Terrain Logistics

Outdoor logistics robots use SEAs in their suspension and drive trains to absorb shock from uneven pavement or gravel. This protects the sensitive internal electronics and ensures the payload remains stable.

Heavy Payload Handling

For forklifts and tuggers, SEAs mitigate the massive impulse forces generated during sudden stops or starts. This extends the lifespan of the transmission and gears, reducing maintenance downtime.

Dynamic Docking

When AGVs dock for charging or material transfer, SEAs allow for "soft" contact. The robot can physically press against the dock to ensure a secure connection without over-torquing motors or damaging connectors.

Frequently Asked Questions

What is the primary difference between an SEA and a traditional actuator?

The primary difference is the introduction of a spring element in series with the mechanical transmission. Traditional actuators are "stiff" and connect the motor directly to the load, whereas SEAs have "give," allowing for better force control and shock absorption at the cost of some bandwidth.

Do Series Elastic Actuators reduce the positional accuracy of an AGV?

They can, but it is manageable. Because the output is compliant, high-precision positioning requires sophisticated control algorithms to compensate for the spring deflection. However, for most mobile robotics applications, the accuracy achieved is more than sufficient.

Are SEAs suitable for high-speed applications?

Generally, SEAs have lower bandwidth than rigid actuators, making them less ideal for extremely high-frequency movements. However, for the typical speeds of warehouse AGVs (1-3 m/s), they perform excellently and actually improve stability over bumps.

How does an SEA improve the lifespan of an AGV?

The elastic element acts as a low-pass filter for shock loads. When an AGV hits a bump or crash stop, the spring absorbs the peak impulse energy, protecting the expensive gearbox teeth and motor bearings from brittle fracture or deformation.

Is the control logic for SEAs more complex to implement?

Yes, the control architecture is more complex. You are controlling a system with resonance. It requires cascaded control loops (torque loop inside a position/velocity loop) and careful tuning to prevent oscillation, but modern motor drivers often have built-in support for this.

Can SEAs be retrofitted onto existing AGV fleets?

Retrofitting is difficult because SEAs require additional physical space for the spring mechanism and usually a second encoder to measure the spring deflection. It is usually a design decision made at the chassis development stage.

Does the spring element wear out over time?

Like all mechanical parts, fatigue is a factor, but industrial SEAs use high-grade steel or composite flexures designed for infinite life within their rated deflection range. Routine maintenance usually focuses on the bearings rather than the spring itself.

How do SEAs compare to current-based torque control?

Current-based control is cheaper but suffers from friction and stiction in the gearbox, making low-force control inaccurate. SEAs measure torque at the output (after the gearbox), bypassing friction issues and providing much higher "force fidelity."

What happens if the spring breaks?

This is a critical failure mode. Most SEA designs include mechanical hard stops that limit deflection. If the spring breaks, the system hits these stops and acts like a (loose) rigid actuator, allowing the robot to limp home or brake safely.

Do SEAs consume more power?

It depends on the task. For holding static loads, they are similar to rigid actuators. However, in cyclic tasks (like lifting or walking gaits), the spring can store and release energy, actually reducing overall power consumption compared to rigid systems.

How do I select the right stiffness (k) for my application?

Stiffness selection is a trade-off. Lower stiffness offers better force resolution and safety but lowers bandwidth. Higher stiffness improves positioning speed but reduces shock tolerance. Selection depends on the payload mass and required interaction frequency.

Are SEAs cost-prohibitive for small fleets?

Initially, they are more expensive due to added mechanical complexity and sensors. However, the Total Cost of Ownership (TCO) is often lower due to reduced damage to gearboxes, fewer sensor replacements, and safer operations in shared spaces.