Rocker-Bogie Suspension

The definitive suspension system for high-stability autonomous mobile robots. Designed to maintain constant ground contact and traverse aggressive terrain without compromising payload stability or sensor calibration.

Core Concepts

Differential Mechanism

Uses a differential pivot to connect the left and right sides. When one side lifts, the other is pushed down, ensuring equal wheel pressure.

Spring-Less Design

Unlike automotive suspension, this system relies on rigid links and geometry rather than springs, reducing bounce and improving sensor stability.

Obstacle Climbing

Capable of climbing obstacles up to twice the wheel diameter while keeping all six wheels in contact with the ground surface.

Body Stability

The chassis pitch angle is averaged between the two sides, meaning the body tilts significantly less than the terrain angle.

Independent Drive

Typically utilizes individual motors for each of the six wheels, providing superior traction control and redundancy in case of motor failure.

Static Stability

Designed for low-speed, high-torque applications where keeping the center of gravity stable is more critical than high-speed cornering.

How It Works

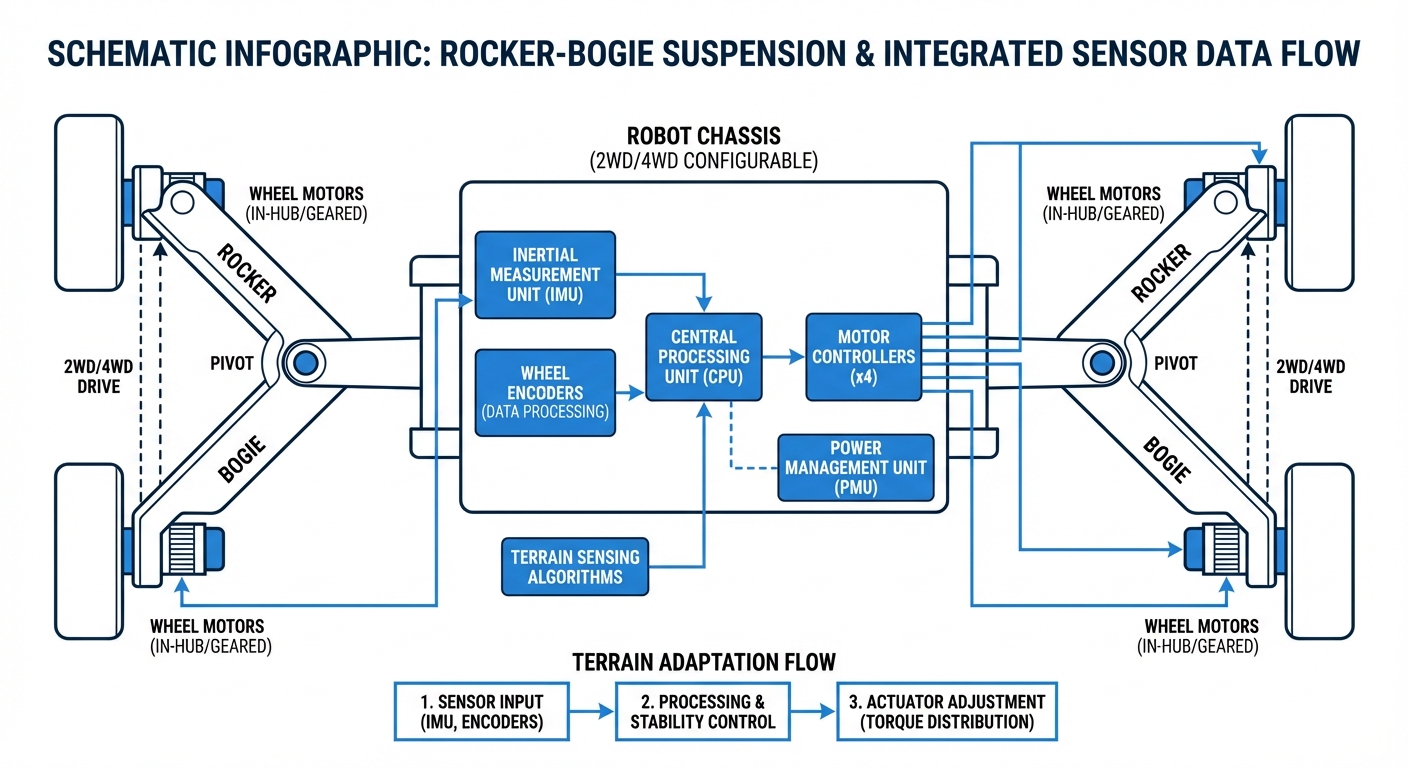

The term "Rocker-Bogie" refers to the two main linkages that make up the suspension on either side of the chassis. The "Rocker" is the larger link connected directly to the robot body via a pivot. The "Bogie" is a smaller link connected to the front of the Rocker.

The key to its efficacy is the lack of rigid axles between the left and right wheels. Instead, a differential bar or gear connects the port and starboard rocker pivots. This allows the bogies to articulate independently while the differential averages the angle.

In practical AGV applications, this means if one wheel climbs a 10cm curb, the main body of the robot only lifts approx 5cm, maintaining the horizon for LiDAR and visual SLAM cameras.

Real-World Applications

Last-Mile Delivery

Delivery robots that must traverse sidewalks, navigate curb cuts, and handle cracked pavement or snow without toppling groceries or packages.

Industrial Inspection

Robots deployed in oil & gas facilities or construction sites where the ground is littered with debris, cables, and uneven metal grating.

Search and Rescue

Small-scale AGVs designed to crawl over rubble and collapsed structures to locate survivors, where suspension failure is not an option.

Agriculture

Monitoring robots moving between crop rows where soil density changes and irrigation furrows present constant mobility challenges.

Frequently Asked Questions

What is the primary advantage of Rocker-Bogie over independent suspension?

The primary advantage is load equalization without springs. Independent suspensions can cause body bounce that confuses navigation sensors. Rocker-Bogie ensures all wheels maintain contact with the ground with roughly equal pressure, providing consistent traction on irregular terrain.

Does this suspension support high-speed movement?

Generally, no. Rocker-Bogie systems are optimized for low-speed stability (typically under 10-15 mph) and high torque. At high speeds, the lack of shock absorption (springs) creates significant vibration and impact stress on the chassis.

Why are six wheels standard for this configuration?

Six wheels offer the optimal balance between complexity and stability. It ensures that even when climbing a step (lifting one wheel pair), four wheels remain grounded to provide traction and stability. Four-wheel variants exist but offer less climbing capability.

How tall of an obstacle can a Rocker-Bogie robot climb?

A properly designed system can climb obstacles up to 1.5 to 2 times the diameter of its wheels. This is significantly higher than standard car suspensions, which usually struggle with obstacles larger than half the wheel diameter.

Does it require special motors or actuators?

It typically requires a motor for every wheel (6 motors total) to maximize traction. While no special actuators are needed for the suspension itself (it is passive), the wheel motors require high torque gearing to utilize the climbing capability effectively.

How does the differential mechanism work?

The differential prevents the robot body from rotating freely around the drive axles. It connects the left and right rockers such that if the left side goes up, the right side is forced down, keeping the main chassis pitch at the average angle of the two sides.

Is Rocker-Bogie suitable for indoor warehouse AGVs?

It is often overkill for perfectly flat concrete floors. However, for older warehouses with cracked floors, cable protectors, or thresholds between facility sections, it provides superior protection for delicate payloads compared to rigid casters.

How is steering handled in this system?

Most implementations use "Skid Steering" (tank turning), varying the speed of left vs. right wheels to turn. More advanced versions (like NASA rovers) use explicit steering servos on corner wheels to reduce tire wear and soil disturbance.

What are the maintenance requirements?

Maintenance is generally lower than spring-shock systems because there are fewer moving parts that wear out under compression. The main focus is on the pivot bearings and the differential linkage, which must be kept clean of debris.

Does the payload weight affect the suspension performance?

Yes, significantly. Because there are no springs to compress, the structural links must be designed to handle the full static load rigidly. Overloading can bend the rocker arms or damage the pivot points, unlike a spring suspension which would simply bottom out.

Is it expensive to implement?

It is more expensive than a simple 4-wheel skid steer due to the mechanical complexity of the linkages, bearings, and the requirement for 6 motors and motor controllers. However, the cost is offset by the reduction in sensor stabilization software needed.