Robotic Power Budgeting

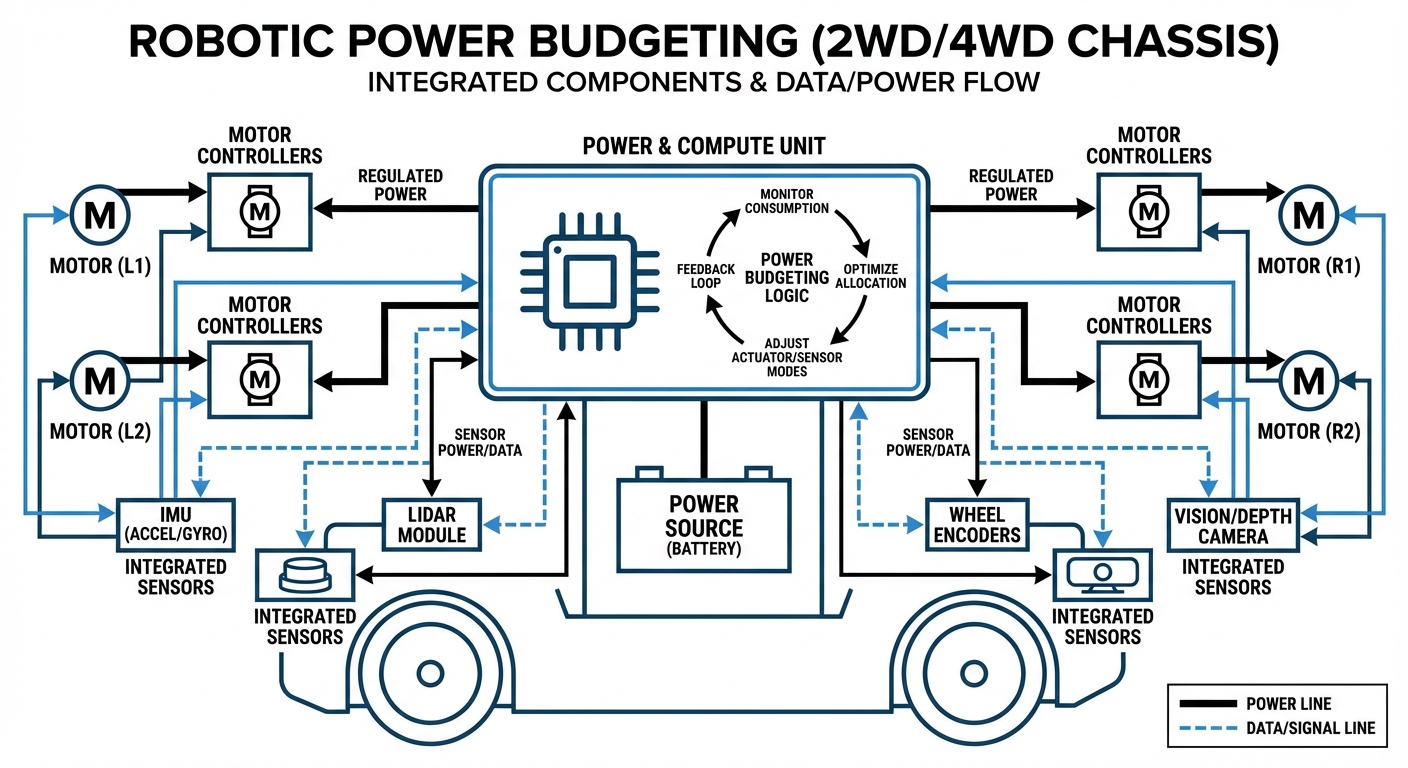

Master the critical engineering process of balancing energy capacity against operational loads. Power budgeting ensures your AGVs and mobile robots achieve their target runtime, handle peak currents safely, and maximize fleet efficiency without unexpected shutdowns.

Core Concepts

Total Power Draw (TPD)

The summation of all components' power consumption, including motors, sensors (LiDAR, Cameras), compute units (GPU/CPU), and communication modules.

Peak vs. Nominal Load

Understanding the difference between average "cruising" power usage and the transient spikes caused by motor acceleration or heavy computation bursts.

Duty Cycle Analysis

Calculations based on the ratio of active time to idle time. A robot that moves 20% of the time has a vastly different budget than a continuous runner.

Safety Margins

Adding a buffer (typically 20-30%) to the power budget to account for component aging, extreme temperatures, and unforeseen mechanical friction.

Conversion Efficiency

Accounting for energy lost as heat during voltage conversion. DC/DC converters are rarely 100% efficient, often introducing 5-15% loss in the system.

Battery Chemistry

Selecting the right power source (LiFePO4, NMC, Lead Acid) based on the calculated budget, discharge rates (C-rate), and weight constraints.

The Calculation Workflow

Creating a robust power budget starts with a granular audit of every electrical component on the robot's bus. Engineers must calculate the Watt-hours (Wh) required for a full mission cycle. This involves mapping out the voltage (V) and current (I) requirements for logic circuits, drive trains, and peripherals.

It is crucial to factor in "Worst Case Scenarios"—such as a robot moving a maximum payload up an incline while processing heavy SLAM data. If the power delivery network (PDN) cannot sustain voltage levels during these spikes, the robot's computer may brownout, causing a system reset.

Finally, the budget dictates the sizing of the battery pack. If the total mission energy is 500Wh and the desired runtime is 4 hours, the battery must be sized significantly larger than 2000Wh to prevent deep discharge cycles that shorten battery life.

Real-World Applications

Warehouse Logistics (AMRs)

In 24/7 fulfillment centers, AMRs rely on tight power budgets to optimize "opportunity charging." Accurate budgeting ensures robots return to docks before depletion, maximizing fleet uptime and throughput.

Outdoor Agriculture

Agricultural robots face uneven terrain which causes unpredictable current spikes in drive motors. Power budgeting here focuses heavily on peak load management and thermal efficiency under solar loads.

Medical Delivery Robots

Hospital robots cannot fail mid-delivery. Conservative power budgeting is used here to guarantee extended runtimes and fail-safe operations for delivering critical medications and supplies.

Heavy Payload AGVs

For robots carrying tons of material, the start/stop inertia creates massive inrush currents. Budgeting dictates the use of capacitor banks or high C-rate batteries to buffer these loads without tripping protection circuits.

Frequently Asked Questions

What is the first step in creating a power budget for a new robot?

The first step is a comprehensive component audit. Create a spreadsheet listing every electrical consumer (motors, sensors, compute, lights), their operating voltage, and their maximum and nominal current draw. Don't forget to include efficiency losses from voltage regulators.

How does temperature affect my robotic power budget?

Temperature has a dual impact. Cold temperatures significantly reduce effective battery capacity and discharge rates, while high temperatures increase the resistance in conductors and reduce the efficiency of motors and electronics, requiring active cooling which consumes even more power.

What is a safe margin of error for battery capacity?

Industry standard suggests a 20-30% safety margin. If your calculations show you need 1000Wh for a shift, size the battery for at least 1200Wh-1300Wh. This accounts for battery degradation over time, unexpected payloads, and imperfect charging cycles.

How do I calculate the power consumption of a DC motor?

While Voltage × Current = Power (Watts), motors are dynamic. You must calculate power at different states: acceleration (peak current), constant velocity (nominal current), and holding torque (if applicable). Use the root mean square (RMS) current for thermal sizing, but peak current for battery C-rate sizing.

Why do I need to account for DC/DC converter efficiency?

Voltage conversion is never free. If a 12V regulator is 90% efficient, 10% of the energy is lost as heat. In a complex robot with multiple voltage rails (5V, 12V, 24V), these compounding losses can account for a significant portion of the total energy budget.

Does software optimization impact the power budget?

Yes, significantly. Efficient path planning reduces travel distance. Implementing "sleep modes" for sensors or compute modules when the robot is idle can extend runtime by hours. Software that manages acceleration curves can also reduce peak current spikes.

What is the impact of LiDAR and Depth Cameras on power?

Perception sensors are power hungry. A 3D LiDAR can consume 8-15W, and processing that point cloud data requires heavy GPU usage, often adding another 15-30W. For a small robot, perception can sometimes consume more power than locomotion.

How does regenerative braking factor into the budget?

For robots with high mass and frequent stops, regen braking can recover 5-15% of energy. However, it is safer to treat this as "bonus" energy rather than relying on it in the core budget, as its effectiveness depends heavily on terrain and operational patterns.

What happens if I under-budget for "Inrush Current"?

Inrush current occurs when devices first turn on (capacitors charging). If not budgeted, this spike can trigger the battery's BMS (Battery Management System) over-current protection, causing the robot to shut down immediately upon startup or when activating a heavy payload.

Should I calculate cabling losses?

For high-current robots, yes. Voltage drop across long or thin wires ($\Delta V = I \times R$) dissipates power as heat. Using appropriately gauged wires is essential to ensure the power actually reaches the motors rather than heating up the chassis.

How does battery aging affect the budget over time?

Batteries lose capacity with cycle count. A budget that works for a new battery (100% capacity) might fail after a year when the battery is at 80% health. Always budget against the "End of Life" capacity of the battery, not the fresh capacity.