Robotic Manipulator Arms

Transform standard autonomous guided vehicles (AGVs) into versatile mobile manipulators capable of complex pick-and-place operations. By integrating multi-axis articulated arms with mobile bases, facilities achieve dynamic machine tending and item-level handling without fixed infrastructure.

Core Concepts

Degrees of Freedom (DoF)

The number of independent joints defines the arm's flexibility. 6-DoF allows the gripper to reach any point in space at any orientation, critical for shelf picking.

Visual Servoing

Unlike fixed robots, mobile manipulators rely on wrist-mounted cameras to compensate for positioning errors of the AGV base, guiding the hand to the target.

Center of Gravity

Dynamic stability control is essential. The arm controller must communicate with the base to prevent tipping when lifting heavy payloads at full extension.

End-Effectors

The tooling at the end of the arm defines utility. Options range from parallel grippers and vacuum suction cups to electric screwdrivers for assembly tasks.

Collaborative (Cobot)

Modern mobile arms use torque sensors to detect collisions immediately, allowing them to work safely alongside humans without safety cages.

Unified Kinematics

Advanced software treats the AGV wheels and the robot arm as a single kinematic chain, allowing simultaneous movement for smoother operation.

How Integrated Mobile Manipulation Works

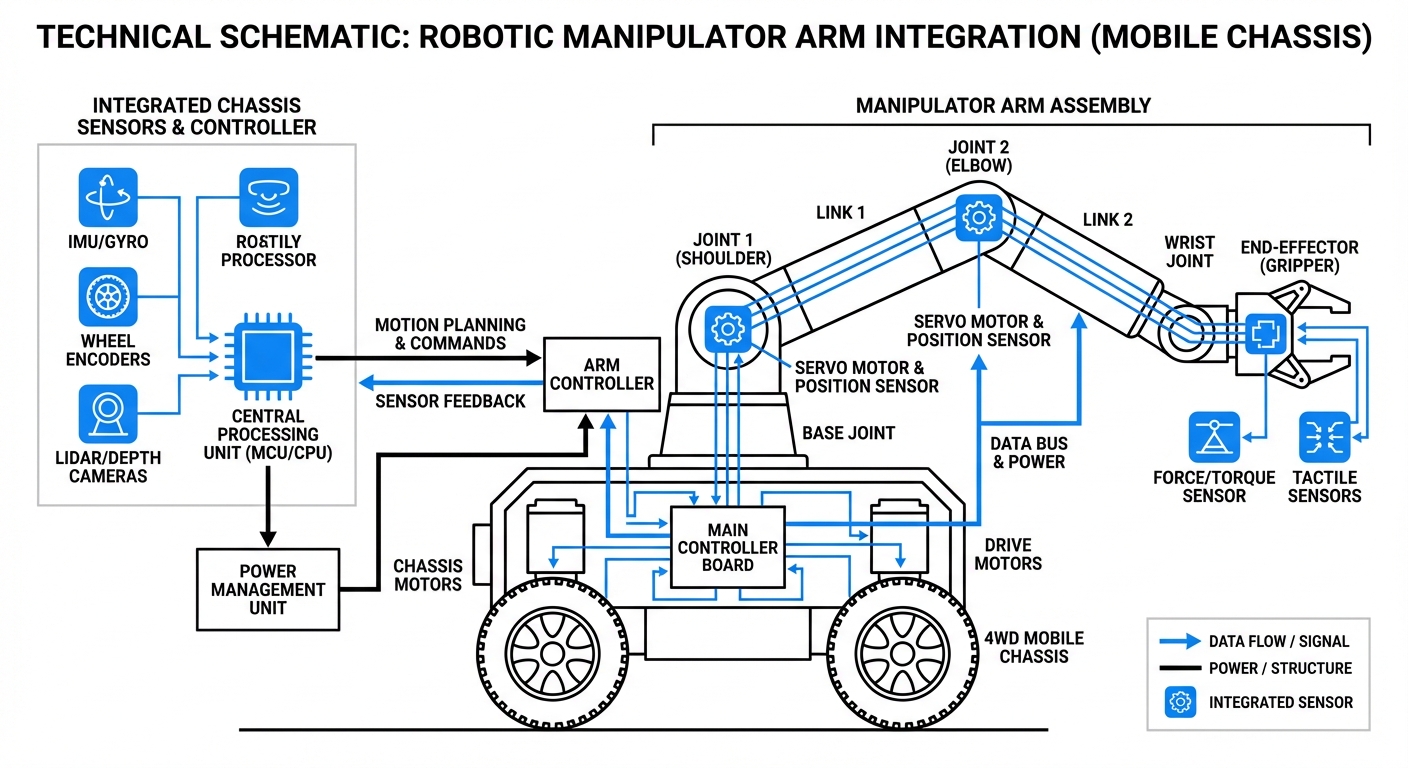

Creating a "Mobile Manipulator" is more complex than simply bolting an industrial arm to a cart. The system requires a unified power and logic architecture. The robot's "brain" must calculate inverse kinematics not just for the arm joints, but relative to the changing position of the mobile base.

The manipulator draws power directly from the AGV's high-capacity traction battery, requiring efficient DC-DC conversion to match voltage requirements. During operation, LIDAR sensors on the base ensure the area is clear, while wrist-mounted RealSense or stereo cameras identify the target object (fiducial markers or AI-based object detection).

Finally, stability algorithms monitor the shifting center of mass. If the arm extends fully with a heavy load, the AGV base may deploy stabilizers or adjust its wheel torque to counter the tipping moment, ensuring safety in dynamic environments.

Real-World Applications

Flexible Machine Tending

Instead of dedicating one robot arm to every CNC machine, a single mobile manipulator can service a bank of 10 machines, loading raw materials and unloading finished parts as needed.

E-Commerce Piece Picking

Moving beyond pallet transport, manipulator-equipped AGVs can reach into shelving units to pick individual items (totes, boxes, or bottles) for direct order fulfillment.

Semiconductor Cleanrooms

Mobile manipulators handle delicate wafer cassettes (FOUPs/SMIFs) between process tools, reducing human contamination and vibration risks in ISO Class 1 environments.

Laboratory Automation

In bioscience facilities, these robots transport microtiter plates between incubators, liquid handlers, and readers, allowing 24/7 unattended high-throughput screening.

Frequently Asked Questions

What is the difference between a standard AGV and a Mobile Manipulator?

A standard AGV is designed solely for transportation (A to B) of goods. A Mobile Manipulator combines this mobility with a robotic arm, allowing the robot to interact with its environment—picking up objects, pressing buttons, or loading machines—rather than just moving them.

How does the robot handle power consumption for both driving and the arm?

Mobile manipulators typically use a shared Li-ion battery bank. The system is designed with a power distribution board that regulates voltage for the sensitive arm controller while managing high-current spikes from the drive motors. Battery sizing is critical to ensure a full shift of operation.

Does the robot arm move while the AGV is driving?

In most industrial safety configurations, the arm is parked in a safe, compact position during transit to lower the center of gravity and prevent collisions. However, advanced "whole-body control" algorithms are emerging that allow simultaneous motion for faster cycle times in controlled zones.

How precise is a mobile manipulator compared to a fixed industrial robot?

Fixed robots rely on rigid mounting for sub-millimeter precision. Mobile bases have suspension compliance and navigation errors (±10mm). To compensate, mobile manipulators use "eye-in-hand" cameras to visually lock onto the target just before grasping, correcting the base's inaccuracy.

What happens if the arm picks up something too heavy?

Modern arms have current monitoring in their joints that detects payload weight. If the weight exceeds the safe limit for the current arm extension (which could cause tipping), the system will trigger an emergency stop or refuse the lift command to protect the hardware.

Do I need to program the AGV and the arm separately?

Ideally, no. We use unified software frameworks (often based on ROS 2) where a single "mission" controls both. For example, a command like "Pick object at Station A" automatically triggers navigation, docking, arm deployment, grasping, and undocking sequences.

What safety standards apply to mobile manipulators?

This is a complex area overlapping several standards. The primary ones are ISO 3691-4 (for driverless trucks) and ISO 10218-1/2 (for robots). The combined system usually requires a specific risk assessment (ISO 12100) to address hazards like arm extension while moving.

Can these robots work on uneven floors?

Mobile manipulators prefer flat, smooth industrial concrete. Uneven floors introduce pitch and roll into the base, which moves the end-effector significantly. While suspension helps, severe floor gradients make precision docking and picking difficult and may require deployable stabilizer legs.

What is the typical payload capacity?

Collaborative mobile arms usually handle payloads between 3kg and 16kg. While the arm might be strong enough to lift more, the limiting factor is often the stability of the mobile base (counterweight) rather than the motor strength of the arm itself.

How do they interface with legacy machines?

This is a key advantage. Unlike automated conveyors that require ripping up the floor, mobile manipulators can press physical buttons or open doors on legacy equipment, allowing you to automate older machines without expensive electrical retrofitting or PLC integration.

What maintenance is required?

Routine maintenance involves checking wheel wear (for navigation accuracy), lubricating arm joints, and inspecting internal cable routing which can fatigue faster due to the vibrations of mobility. Sensors and cameras must be kept clean of dust to maintain visual accuracy.

Is WiFi latency an issue for control?

The robot's safety loops and immediate motion planning are handled onboard to avoid latency issues. WiFi is used for high-level fleet management (task dispatching). Therefore, temporary network dropouts usually do not stop the robot from completing its current pick-and-place task.