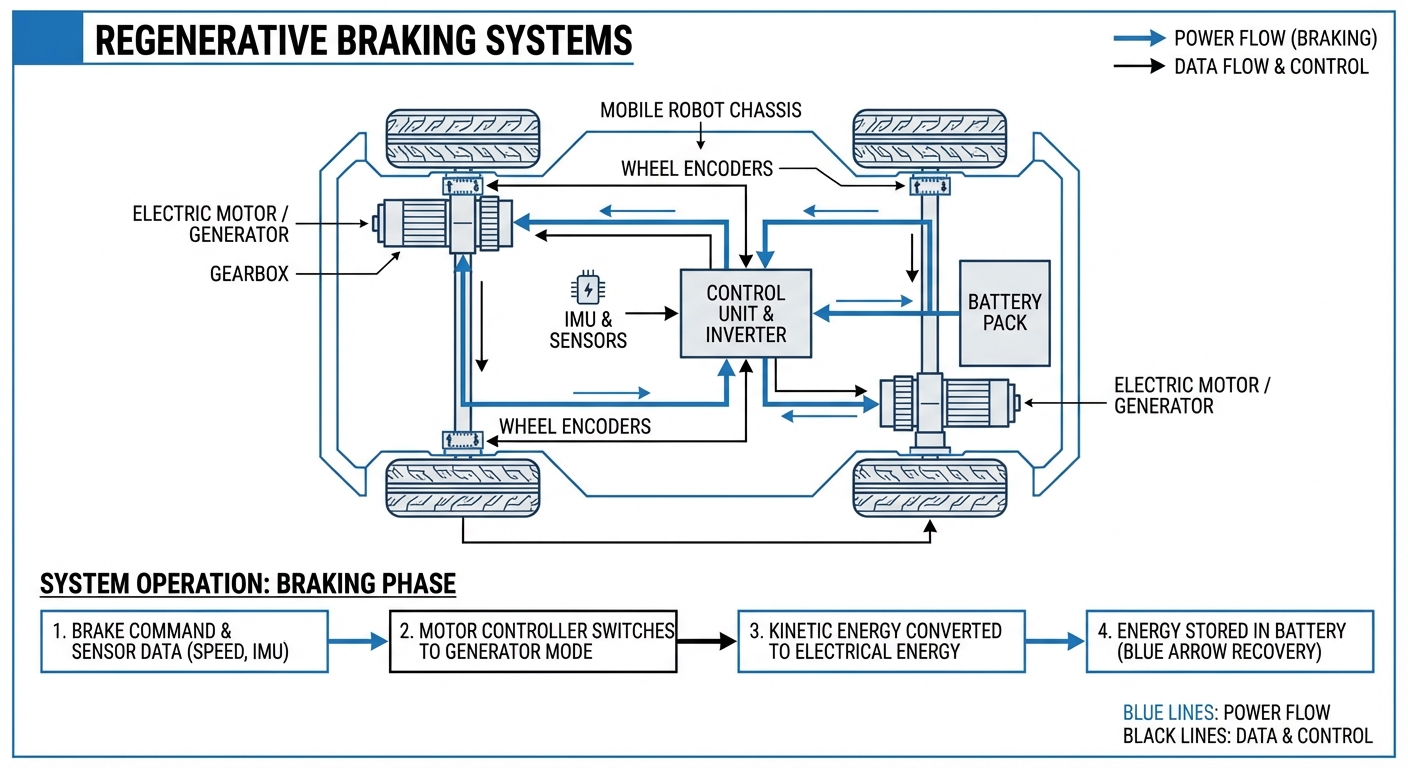

Regenerative Braking Systems

Transform kinetic energy into reusable power, extending the operational lifecycle of Autonomous Guided Vehicles (AGVs). This critical technology captures energy during deceleration, reducing battery strain and optimizing fleet efficiency in high-demand environments.

Core Concepts

Energy Recovery

The fundamental principle where the electric motor acts as a generator during deceleration, converting kinetic energy back into electrical energy to recharge the onboard battery.

Four-Quadrant Control

Sophisticated motor controllers operate in four quadrants, seamlessly switching between driving (motoring) and braking (generating) modes in both forward and reverse directions.

Battery Absorption

The battery management system (BMS) must accept high current spikes during braking. Lithium-ion chemistries are particularly effective at absorbing this rapid influx of energy compared to lead-acid.

Overvoltage Protection

Safety circuits prevent damage when the battery is fully charged. If the battery cannot accept more current, the system diverts energy to a braking resistor (rheostatic braking).

Duty Cycle Optimization

In scenarios with frequent starts and stops, regenerative braking significantly reduces heat buildup in mechanical brakes, extending maintenance intervals and component life.

Torque Control

Precise modulation of the regenerative torque allows for smooth, controlled deceleration profiles, which is crucial for AGVs carrying fragile loads or liquid contents.

How It Works

In a standard electric drive system, the battery supplies current to the motor to generate torque. When a "Regen" command is issued, the flow of electricity reverses. The AGV's momentum drives the motor, effectively turning it into a generator.

The motor controller adjusts the firing angle of its internal transistors (MOSFETs or IGBTs) to boost the voltage generated by the motor until it exceeds the battery's terminal voltage. Physics dictates that current flows from high potential to low potential, causing energy to flow back into the battery pack.

This process relies heavily on the Back Electromotive Force (Back-EMF). As long as the rotational speed creates sufficient Back-EMF, the controller can harvest energy. This is most effective at higher speeds and diminishes as the robot comes to a complete halt, where mechanical holding brakes usually take over.

Real-World Applications

High-Throughput Warehousing

AMRs in fulfillment centers operate in stop-and-go traffic patterns. Regenerative braking captures energy from hundreds of stops per hour, potentially extending runtime by 15-20% per shift.

Heavy Payload Transport

For AGVs moving pallets over 1 ton, the kinetic energy generated during movement is massive. Capturing this energy prevents brake fade and significantly reduces thermal stress on components.

Ramp & Slope Navigation

When an AGV descends a ramp, gravity accelerates the mass. Regenerative braking acts as a speed governor, converting gravitational potential energy into electrical charge while maintaining safe descent speeds.

Cleanroom & Hospital Logistics

Mechanical brakes generate dust and particulate matter due to friction. Regenerative braking is contactless, making it ideal for sterile environments where reducing airborne particulates is mandatory.

Frequently Asked Questions

What is the difference between Regenerative Braking and Dynamic Braking?

Regenerative braking routes the energy back into the battery for reuse. Dynamic (or Rheostatic) braking dissipates that energy as heat through a resistor grid. While regenerative is more efficient, dynamic braking is often used as a backup when the battery is fully charged.

How much energy can actually be recovered?

Typically, AGVs can recover between 10% to 20% of energy usage depending on the duty cycle. Applications with heavy loads and frequent start-stop cycles (like shuttles) see the highest return, whereas continuous long-distance travel sees less benefit.

Does regenerative braking work when the battery is 100% charged?

No. If the battery is full, pumping current into it can cause dangerous overvoltage. Modern BMS units will disconnect the regeneration path, and the motor controller must switch to a resistive dummy load or mechanical brakes to stop the vehicle safely.

Can regenerative braking bring an AGV to a complete stop?

Not entirely. As speed decreases, the back-EMF drops, reducing the braking force. While it can bring a robot to a near-halt, a mechanical parking brake or electromagnetic brake is always required to hold the vehicle completely stationary.

Does this technology require special motors?

Most modern AC induction and Brushless DC (BLDC) motors support regeneration naturally. The critical component is the motor controller (drive), which must support four-quadrant operation to manage the reverse flow of current.

How does battery chemistry affect regeneration efficiency?

Lithium Iron Phosphate (LiFePO4) and Li-NMC batteries usually have lower internal resistance than Lead-Acid, allowing them to accept the high-current pulses of braking more efficiently. Lead-acid batteries may heat up or fail to absorb the energy quickly enough.

Is there a maintenance benefit to using this system?

Yes. Because the electric motor provides the primary braking force, the physical brake pads or shoes experience minimal wear. This drastically reduces the downtime and cost associated with replacing worn mechanical brake components.

What happens if the emergency stop (E-Stop) is pressed?

In an E-Stop event, safety regulations usually dictate the engagement of mechanical brakes immediately. While some controllers attempt to regen briefly to slow down, the priority is immediate stopping power, often bypassing the regen circuit for fail-safe mechanical locking.

Does regenerative braking generate heat?

Yes, the motor controller and battery will generate heat during the conversion process. However, this is generally less than the heat generated by friction brakes. Proper thermal management of the electronics enclosure is still required.

Is it cost-effective for small AGV fleets?

For small fleets with light payloads, the ROI might be slower. However, since most modern industrial motor controllers include this feature by default, the implementation cost is low. The primary cost is ensuring the battery system is robust enough to handle the regen current.

Can we retrofit existing robots with regenerative braking?

It depends on the existing motor controller. If the current controller is a simple 1-quadrant or 2-quadrant drive, it must be replaced with a 4-quadrant controller. Wiring and battery protection circuits would also need assessment.

How does it impact navigation accuracy?

It can actually improve it. Electronic braking allows for extremely precise control of deceleration curves compared to the variable friction of mechanical brakes, leading to more consistent stopping distances and positioning.