Power Distribution Boards

The central nervous system of autonomous mobile robots. PDBs efficiently route energy from high-capacity batteries to motors, sensors, and compute units, ensuring stable voltage and critical overload protection for reliable fleet operations.

Core Concepts

Voltage Regulation

AGVs often run on 24V or 48V main packs, but sensors require 5V or 12V. PDBs integrate high-efficiency BECs (Battery Elimination Circuits) to step down voltage without generating excessive heat.

Current Handling

Designed with thick copper traces and reinforced PCBs to handle the massive inrush currents required by drive motors while maintaining stable power for sensitive electronics.

Short Circuit Protection

Integrated fuses, PTCs (resettable fuses), and electronic breakers isolate faults instantly, preventing a single component failure from damaging the main battery or the entire robot.

Power Monitoring

Smart PDBs include shunt resistors and current sensors that communicate with the main controller via I2C or CAN bus, providing real-time data on power consumption.

EMI Filtering

Clean power is crucial for LiDAR and IMUs. PDBs utilize capacitors and ferrite beads to filter out electromagnetic interference generated by brushed or brushless motors.

Thermal Management

High current generates heat. Advanced PDBs incorporate aluminum substrates or heavy-duty heatsinks to dissipate thermal energy, ensuring components stay within safe operating ranges.

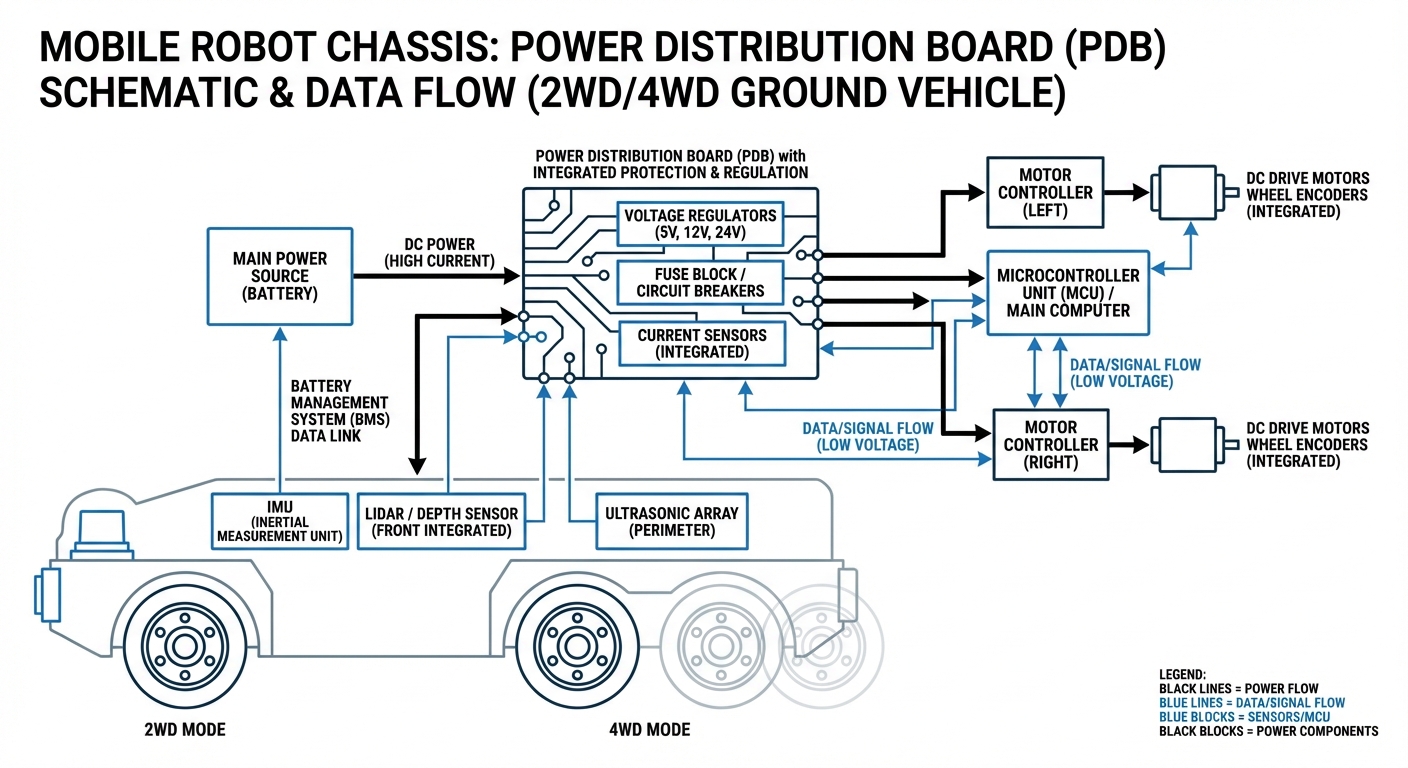

How It Works: The Power Architecture

At the heart of the system, the PDB acts as a smart manifold for electrical energy. It receives the raw, unregulated high-voltage input from the lithium-ion battery pack via high-amperage connectors (such as XT90 or Anderson Powerpoles).

This input is immediately split into two distinct paths. The "dirty" path routes high current directly to the ESCs (Electronic Speed Controllers) and motors, often bypassing sensitive regulation to maximize torque delivery. The "clean" path passes through Buck converters (step-down regulators).

These regulators stabilize the voltage to precise levels (typically 5V for microcontrollers like Arduino/ESP32, and 12V/19V for single-board computers like Jetson or Raspberry Pi), ensuring the robot's brain never browns out during heavy acceleration.

Real-World Applications

Warehouse AMRs

Automated Mobile Robots in logistics require PDBs that can handle 24/7 operation with high burst currents for lifting heavy pallets while maintaining Wi-Fi connectivity.

Agricultural Rovers

Outdoor farming robots need PDBs with IP-rated enclosures and robust filtering to handle long cable runs and fluctuating loads from uneven terrain.

Medical Delivery Bots

Hospital environments demand ultra-quiet, efficient power distribution to maximize battery life and ensure zero interference with sensitive medical equipment.

Inspection Drones

Aerial robotics rely on lightweight PDBs where every gram counts, prioritizing high power density and integrated OSD (On-Screen Display) telemetry overlays.

Frequently Asked Questions

What is the difference between a PDB and a BMS?

A Battery Management System (BMS) focuses on the health of the battery itself, balancing cells and preventing over-charge/discharge. A Power Distribution Board (PDB) focuses on routing that power to the rest of the robot, regulating voltages for different components, and splitting the main power line.

How do I choose the right amperage rating for my PDB?

Calculate the maximum continuous current draw of all your motors combined, plus a 20-30% safety margin. If your four motors draw 10A each at peak load, you need a PDB capable of handling at least 50A continuous, with higher burst handling capabilities.

What is a "Smart" PDB?

A Smart PDB includes a microcontroller and communication interface (like CAN Bus, UART, or I2C). It reports telemetry data such as current consumption, voltage levels, and temperature back to the robot's main computer, allowing for predictive maintenance and dynamic power management.

Why do I need separate voltage rails (5V, 12V)?

Different components have different needs. Logic circuits and microcontrollers usually need 3.3V or 5V, while peripherals like LiDARs, cameras, and heavy-duty servos often run on 12V. Using a PDB with built-in regulators eliminates the need for multiple separate batteries.

Can a PDB handle regenerative braking?

Yes, but the design must account for it. When motors brake, they generate reverse current. The PDB and the upstream BMS must be capable of accepting this reverse flow without triggering over-voltage protection, or include a shunt circuit to dissipate the excess energy as heat.

What connector types are standard for Robotics PDBs?

For small to medium robots, XT30, XT60, and XT90 connectors are industry standards due to their reliability and current handling. For larger industrial AGVs, Anderson Powerpole connectors or heavy-duty screw terminals are preferred for their robustness and modularity.

Do PDBs protect against reverse polarity?

Not all PDBs do. While some advanced boards include a diode or MOSFET circuit to block reverse current, basic PDBs may be damaged if the battery is connected backwards. Always check the datasheet or use polarized connectors to physically prevent this error.

How does a PDB help with "Ground Loops"?

A well-designed PDB provides a "Star Ground" topology, where all component grounds return to a single point. This minimizes voltage potential differences between components, reducing signal noise and preventing erratic behavior in sensitive sensors.

What is the lifespan of a PDB?

Solid-state PDBs are very durable and can last the lifetime of the robot (5-10 years). However, electrolytic capacitors used for filtering may degrade over time, especially in high-temperature environments. Regular inspection for bulging capacitors or heat discoloration is recommended.

Can I use a Drone PDB for a Ground Robot?

Often, yes. Drone PDBs are high-performance and lightweight. However, ground robots often require different voltage outputs (like 12V/19V for computers vs 5V for flight controllers) and may need more robust mounting options than the vibration-dampened mounts used on drones.