Pneumatic Artificial Muscles

Mimicking biological muscle contraction through air pressure, Pneumatic Artificial Muscles (PAMs) offer high power-to-weight ratios and inherent compliance. These soft actuators are revolutionizing safety and efficiency in AGV lifting mechanisms, collaborative robotics, and shock absorption systems.

Core Concepts

The McKibben Effect

The fundamental principle where an internal bladder expands radially against a braided mesh sleeve, causing axial contraction and generating significant pulling force.

Inherent Compliance

Unlike rigid motors, compressed air provides natural springiness. This acts as a shock absorber, protecting AGV chassis components from sudden impacts or uneven terrain.

High Power Density

PAMs are exceptionally lightweight compared to the force they exert. A muscle weighing a few hundred grams can lift hundreds of kilograms, maximizing AGV payload capacity.

Non-Linear Control

The relationship between pressure and contraction length is non-linear and exhibits hysteresis, requiring sophisticated control algorithms for precise positioning tasks.

Antagonistic Setup

Since PAMs only generate force when contracting (pulling), they are often arranged in antagonistic pairs—like a bicep and tricep—to achieve bidirectional motion.

Clean Operation

Operating on compressed air eliminates the risk of hydraulic fluid leaks, making PAMs ideal for cleanroom AGVs and food processing environments.

How It Works

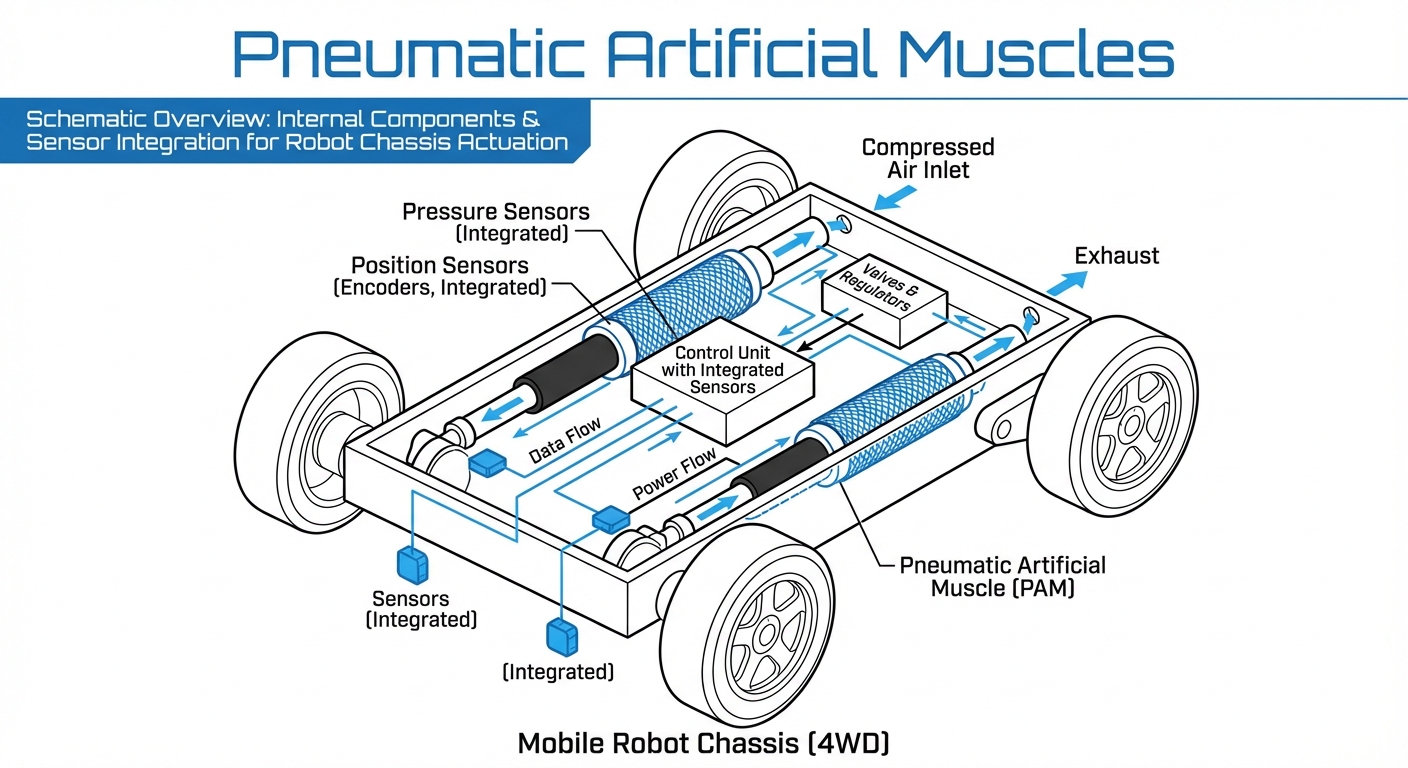

A Pneumatic Artificial Muscle consists of an elastic inner tube surrounded by a braided mesh sleeve, typically made of high-strength nylon or metal fibers. The ends are sealed with fittings that allow compressed air to enter the inner tube.

When the internal pressure increases, the inner rubber bladder expands. However, the outer geometric mesh constrains this expansion. The mesh geometry dictates that as the diameter of the muscle increases, its length must decrease. This geometric scissor-action generates a powerful contraction force.

Unlike traditional pneumatic cylinders that use a piston, PAMs have no sliding parts. This eliminates "stick-slip" friction, allowing for smooth, jerky-free motion immediately upon activation. This smoothness is critical for AGVs carrying sensitive payloads or operating in close proximity to human workers.

Real-World Applications

Soft Grippers for Warehousing

PAMs power adaptive grippers on mobile manipulators. The natural compliance allows the robot to handle irregular, fragile, or varying objects without complex force sensors, reducing product damage rates in fulfillment centers.

Active Suspension Systems

High-speed AGVs use PAMs as variable stiffness springs. By adjusting air pressure dynamically, the robot can stiffen suspension for stability during turning or soften it to dampen vibrations when traversing uneven floors.

Heavy Payload Lifting

Due to their immense force generation at the beginning of the stroke, PAMs are used in scissor-lift mechanisms on Autonomous Mobile Robots (AMRs) to elevate pallets weighing over 1000kg with minimal actuator weight.

Collaborative Assembly (Cobots)

In factories where robots work alongside humans, rigid actuators pose injury risks. PAM-driven arms are inherently safe; if a collision occurs, the air compressibility absorbs the energy, preventing injury to the operator.

Frequently Asked Questions

What is the main advantage of PAMs over hydraulic cylinders in robotics?

The primary advantages are weight and cleanliness. PAMs are significantly lighter than hydraulic cylinders and pumps, improving the robot's battery efficiency. Additionally, they use air rather than oil, eliminating the risk of hazardous fluid leaks in sensitive environments.

How much can a Pneumatic Artificial Muscle contract?

Generally, a PAM can contract by approximately 25% to 35% of its resting length. While this stroke is shorter than telescopic cylinders, the force generated during this contraction is exceptionally high, making them ideal for short-stroke, high-power applications.

Does my AGV need a large air compressor to run these?

Not necessarily. While a compressed air source is required, many mobile robots utilize compact onboard micro-compressors and accumulator tanks. Because PAMs are efficient and air is compressible, the system can often operate on stored pressure for short bursts without continuous heavy pumping.

Are PAMs difficult to control precisely?

They present more control challenges than electric stepper motors due to the non-linear elasticity of air and hysteresis in the rubber bladder. However, modern PID controllers and proportional pressure valves allow for accuracy sufficient for most material handling and suspension tasks.

What is the typical lifespan of a pneumatic muscle?

Lifespan depends heavily on the load and operating pressure but typically ranges from hundreds of thousands to several million cycles. The most common failure mode is wear on the internal bladder from friction against the outer mesh, which can be mitigated with proper lubrication and pressure limits.

Can PAMs hold a load in a fixed position without power?

If the air valve is closed to seal the muscle, it can hold a load (unlike a de-energized electric motor). However, over long periods, minor air leakage may cause the position to drift, so mechanical locking mechanisms are recommended for long-duration holding.

Why are they considered "safer" for human interaction?

They possess "passive compliance." If a human arm blocks a PAM-driven robot arm, the air inside the muscle simply compresses further rather than forcing the robot arm through the obstruction with infinite stiffness. This naturally limits impact forces.

Do PAMs require lubrication?

They do not require external lubrication like gears or chains. However, the air supply should be clean, and sometimes a slight mist of oil in the pneumatic line helps reduce internal friction between the bladder and the mesh, extending service life.

Can they operate in wet or dusty environments?

Yes, PAMs are excellent for harsh environments. The internal mechanism is sealed against the air supply, and the outer mesh is robust. Unlike electric motors which need complex sealing (IP ratings), PAMs can often be washed down or operate in dusty warehouses without modification.

How does temperature affect performance?

Extreme cold can make the rubber bladder brittle, while extreme heat can soften it or degrade the mesh. However, standard commercial PAMs operate reliably within typical industrial temperature ranges (-20°C to +80°C).

Are they cost-effective compared to electric actuators?

The actuator itself is often cheaper than a high-torque precision servo motor and gearbox. However, the total system cost must include valves, air regulation, and the compressor source. For high-force, low-precision tasks, they are generally very cost-effective.

How do I size a PAM for my AGV lift?

Sizing involves calculating the required force at the start of the contraction (where force is highest) and the end of the stroke. Manufacturers provide force-contraction curves. You must ensure the muscle diameter and length provide enough force throughout the entire range of motion needed.