Piezoelectric Actuators

Unlock nanometer-precision motion control and rapid response times for next-generation Automated Guided Vehicles (AGVs). Piezoelectric technology bridges the gap between digital signals and physical displacement with solid-state reliability.

Core Concepts

Inverse Piezo Effect

The actuator expands when an electric field is applied. This solid-state conversion allows for movement without gears, reducing wear and maintenance in AGV fleets.

Microsecond Response

Piezo actuators react in microseconds, significantly faster than electromagnetic motors. This is critical for active vibration damping and high-speed sorting mechanisms.

Nanometer Precision

With resolution limited only by the drive electronics, these actuators provide infinite resolution within their stroke, perfect for optical alignment in navigating robots.

High Blocking Force

Despite their compact size, stacked piezo actuators can generate thousands of Newtons of force, allowing them to handle heavy loads or clamp components securely.

Zero Backlash

Because the motion is based on atomic lattice expansion rather than rotating gears, there is zero "play" or backlash, ensuring absolute positional repeatability.

Energy Efficiency

Piezo actuators consume virtually zero power when holding a static position. This is a massive advantage for battery life in mobile robots during idle holding states.

How It Works

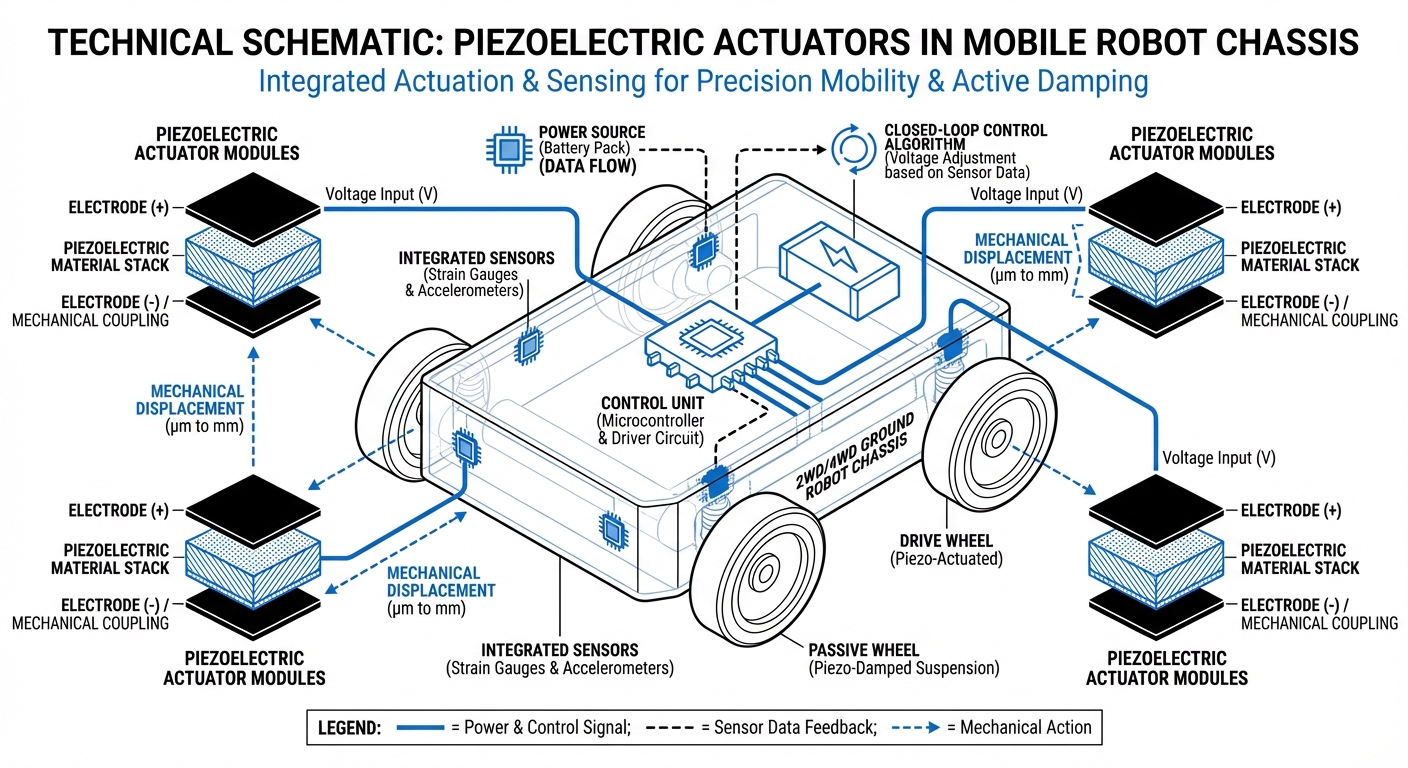

Piezoelectric actuators utilize sophisticated ferroelectric ceramic materials, most commonly Lead Zirconate Titanate (PZT). When an electrical potential is applied across the material, the crystal lattice deforms, resulting in macroscopic expansion.

To achieve useful motion for robotics, these actuators are typically constructed in "stacks." Hundreds of thin ceramic layers are interspersed with electrodes and glued together. This stacking multiplies the displacement, allowing the actuator to achieve strokes suitable for mechanical actuation while keeping voltage requirements manageable.

In an AGV context, a controller sends a precise voltage signal to the actuator. The actuator responds instantly with a proportional expansion. This linear motion can be used directly to push a load, or amplified via flexure hinges to drive a gripper, adjust a sensor lens, or dampen chassis vibration.

Real-World Applications

Active Vibration Damping

In warehouse AGVs carrying delicate electronics or liquids, piezo actuators act as active suspension elements. They counter-act floor irregularities in milliseconds to keep the payload perfectly stable.

Precision Micro-Grippers

For mobile manipulation robots, piezo-driven grippers allow for the handling of extremely small or fragile components with precise force control that pneumatic systems cannot match.

LiDAR & Sensor Scanning

Piezo actuators are used to oscillate mirrors or lenses in navigation sensors (LiDAR/Cameras). This allows for high-speed scanning and focus adjustment without bulky motors.

Micro-Fluidic Dispensing

In specialized medical or industrial mobile robots, piezo elements drive dispensing valves, ejecting precise droplets of lubricants, glues, or reagents with high repeatability.

Frequently Asked Questions

What distinguishes a piezoelectric actuator from a solenoid?

Piezo actuators offer significantly higher force density and faster response times (microseconds vs. milliseconds) compared to solenoids. Additionally, piezos offer proportional control with infinite resolution, whereas solenoids are typically binary (on/off) devices.

How much travel (stroke) can these actuators achieve?

Standard stacked actuators typically travel about 0.1% to 0.15% of their total length, usually ranging from 10 to 200 micrometers. However, amplified piezo actuators use flexure mechanisms to increase this stroke to several millimeters, trading some force for distance.

Are piezo actuators suitable for battery-powered AGVs?

Yes, they are highly efficient. While they behave like capacitors and require energy to charge (move), they consume virtually zero energy to hold a static position. This makes them ideal for applications requiring long hold times without draining the robot's battery.

Do they require high voltage to operate?

Yes, typical multilayer piezo actuators operate between 60V and 150V. However, specialized piezo drivers boost the standard 12V/24V/48V battery voltage of an AGV to the required levels efficiently with very low current requirements.

What is Hysteresis and how does it affect control?

Hysteresis is the difference in displacement between increasing and decreasing voltage for the same voltage value, typically 10-15% in open-loop systems. For high-precision applications, we recommend using actuators with integrated strain gauge sensors and closed-loop controllers to eliminate this effect.

Are piezo actuators fragile?

Piezo ceramics are very strong in compression (pushing) but weak in tension (pulling) and shear. To ensure durability in rough robotics environments, most actuators are pre-loaded (encased in a spring mechanism) to ensure the ceramic is always under compression, protecting it from tensile shocks.

Does temperature affect performance?

Yes, the expansion coefficient changes with temperature. Furthermore, operation must stay well below the "Curie Temperature" (usually >150°C), where the material loses its piezoelectric properties. Industrial AGV designs should account for thermal management in continuous dynamic applications.

What is the "Creep" phenomenon?

Creep is a slow, continued expansion over time after the voltage has stabilized. It is logarithmic and predictable. Like hysteresis, this is easily corrected using closed-loop control systems found in modern robotics controllers.

Can piezo actuators generate heat?

In static operation, they generate no heat. However, in high-frequency dynamic operation (oscillating hundreds of times per second), the internal dielectric loss generates self-heating. This must be calculated during the design phase for scanning or vibration damping applications.

Are they affected by magnetic fields?

No. Piezoelectric actuators are non-magnetic and are unaffected by magnetic fields. This makes them the only choice for robots operating near MRI machines or high-interference industrial welding equipment where electromagnetic motors would fail or cause interference.

How long do they last?

Solid-state piezo actuators have no wearing parts like gears or brushes. Their lifespan is typically measured in billions of cycles. Failures are usually due to humidity ingress or extreme voltage spikes, both of which are preventable with hermetic sealing and proper driver electronics.

What is the cost comparison to standard servo motors?

Piezo solutions generally have a higher upfront cost than standard DC motors due to the materials and precision manufacturing. However, for applications requiring nanometer precision, non-magnetic operation, or compact high-force density, they provide value that standard servos physically cannot deliver.