PID Controllers

The mathematical heartbeat of precision navigation, PID control bridges the gap between where your robot is and where it needs to be. Essential for smooth line following, accurate speed regulation, and stability in modern AGV fleets.

Core Concepts

Setpoint (SP)

The desired target value your robot aims to achieve. In line following, this is usually "0" (centered directly over the line).

Process Variable (PV)

The actual value measured by sensors. For an AGV, this is the real-time feedback from magnetic or optical sensors indicating current position.

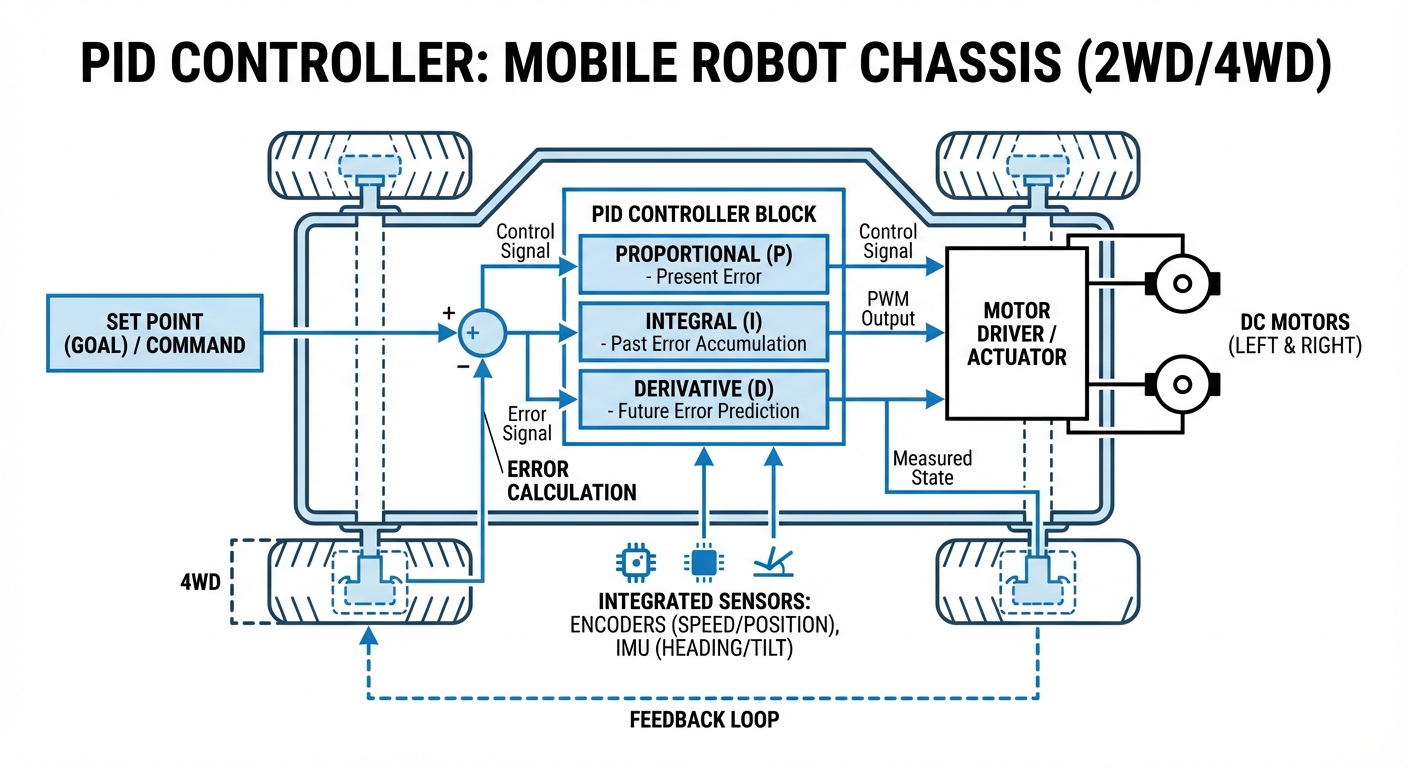

Proportional (P)

Handles the "present" error. The output is directly proportional to the distance from the line. Higher P values mean a stronger reaction to errors.

Integral (I)

Handles the "past" error accumulation. It eliminates steady-state error, ensuring the robot doesn't get stuck slightly off-center.

Derivative (D)

Predicts "future" error based on the rate of change. It acts as a damper, reducing overshoot and oscillation when the robot corrects itself.

Tuning

The process of adjusting the Kp, Ki, and Kd constants. Proper tuning converts a jittery robot into a smooth, efficient machine.

How It Works

The PID control loop is a feedback mechanism widely used in industrial control systems. In the context of an AGV, the cycle begins with sensors detecting the line position relative to the robot's center.

This sensor data creates an "Error Value" (Difference between where the robot is and where it wants to be). The controller algorithm calculates three separate responses: Proportional (current error), Integral (sum of past errors), and Derivative (rate of change).

These three values are summed to produce a control output, which adjusts the PWM (Pulse Width Modulation) sent to the motor drivers. This allows the robot to steer smoothly back to the center line rather than jerking back and forth in a "bang-bang" fashion.

Result: Fluid motion, higher top speeds, and reduced mechanical wear on the drivetrain.

Real-World Applications

Line Following AGVs

The most common use case. PID ensures the robot adheres strictly to magnetic tape or painted lines in warehouses, even around sharp curves or surface irregularities.

Motor Speed Control

Maintaining constant velocity regardless of load or incline. PID increases power when the robot hits a ramp and decreases it on descents to ensure safety.

Robotic Arm Positioning

For AGVs equipped with manipulators, PID ensures the arm moves to precise coordinates without overshooting or vibrating, crucial for pick-and-place operations.

Self-Balancing Robots

Inverted pendulum robots require extremely fast PID loops (often >100Hz) to make micro-adjustments to the wheels to stay upright against gravity.

Frequently Asked Questions

What distinguishes PID from simple On/Off control?

On/Off (Bang-Bang) control applies full power or zero power, causing the robot to zigzag aggressively across the line. PID provides variable power, allowing for smooth curves and corrections proportional to the error, resulting in faster and more stable movement.

Why does my robot oscillate (wobble) heavily?

Oscillation usually indicates that your Proportional (Kp) gain is too high. The robot is overcorrecting for errors, swinging past the line, and then overcorrecting back. Try reducing Kp or increasing the Derivative (Kd) term to dampen the movement.

What is "Integral Windup" and how do I fix it?

Integral Windup occurs when a large error accumulates over time (e.g., the robot is blocked), causing the "I" term to become massive. When the blockage is removed, the robot overshoots wildly. Fix this by clamping the maximum value the Integral term can reach or resetting it when the error crosses zero.

Do I always need all three (P, I, and D) terms?

Not always. Many simple line followers work well with just a PD controller. The Integral term is only necessary if you have a steady-state error, such as a robot that consistently drives slightly to the left of the line due to mechanical drift.

How fast should my PID loop run?

The loop frequency should be significantly faster than the mechanical response time of your robot. For most AGVs, a sampling rate between 50Hz and 100Hz is sufficient, but high-speed balancing robots may require 1kHz or higher.

What is the Ziegler-Nichols tuning method?

It is a heuristic method for tuning PID. It involves setting I and D to zero, increasing P until the system oscillates consistently, and then using that "ultimate gain" and oscillation period to mathematically calculate optimal Kp, Ki, and Kd values.

How does sensor noise affect the Derivative term?

The Derivative term is very sensitive to noise because it calculates the rate of change. Sudden spikes in sensor data can cause violent motor twitches. It is best practice to use a moving average filter on your sensor data before feeding it into the PID algorithm.

Can I implement PID on an Arduino or ESP32?

Absolutely. Modern microcontrollers like Arduino and ESP32 are more than capable of handling float-point math for PID calculations. There are also robust libraries available (like the Arduino PID Library) to simplify implementation.

What is "Derivative Kick" and how do I avoid it?

Derivative Kick happens when the Setpoint is changed instantly, causing a massive spike in the error derivative. To avoid this, calculate the derivative based on the Process Variable (sensor reading) rather than the Error value.

Is PID suitable for non-linear systems?

PID is a linear controller. While it works great for keeping an AGV on a line (mostly linear), it struggles with highly non-linear or unpredictable systems. For complex dynamics, advanced control strategies like Model Predictive Control (MPC) might be required.

How do I map PID output to motor speed?

The PID output is usually added to the left motor speed and subtracted from the right motor speed (or vice versa). You must constrain the final motor values to your hardware's PWM range (e.g., 0-255) to prevent logic errors.

Does battery voltage affect PID performance?

Yes. As battery voltage drops, motors produce less torque for the same PWM value, effectively changing the system's "gain." High-end drivers use voltage compensation, but otherwise, you may need to re-tune or use slightly more aggressive P-gains as the battery drains.