Optical Encoders

The silent architects of precision, optical encoders translate physical motion into digital data. They provide the critical feedback loop required for Autonomous Guided Vehicles (AGVs) to achieve millimeter-level navigation accuracy and smooth motor control.

Core Concepts

Incremental Encoding

Measures relative change in position. Ideal for speed monitoring and velocity control in AGV drive wheels where absolute position isn't critical upon startup.

Absolute Encoding

Assigns a unique digital code to every shaft angle. Essential for robotic arms or steering mechanisms that must know their exact position immediately after a power cycle.

Resolution (CPR)

Counts Per Revolution defines precision. High-resolution optical discs allow for extremely smooth motion profiles and precise stopping at charging stations.

Quadrature Output

Utilizes two channels (A and B) offset by 90 degrees. This allows the robot controller to determine not just speed, but also the direction of rotation.

The Code Disc

The heart of the sensor, usually made of glass or metal with etched microscopic lines. It interrupts the light beam to create the pulse signal.

Interference Immunity

Unlike magnetic encoders, optical variants are immune to magnetic interference, making them safe to use near high-power electric motors used in heavy-payload AGVs.

How It Works

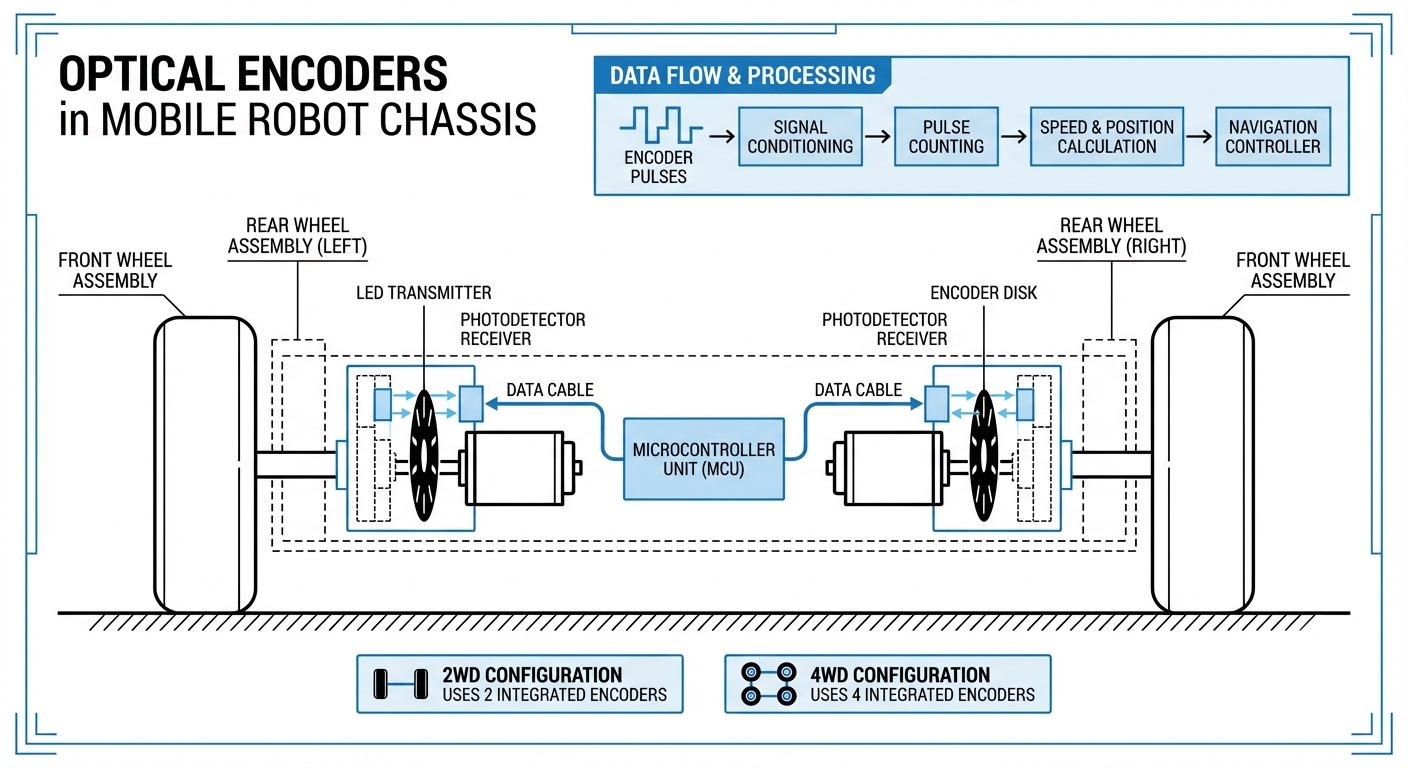

Optical encoders operate on a simple yet highly effective principle of light interruption. Inside the housing, an LED light source beams light towards a photodetector. Between them spins a code disc attached to the motor shaft.

This disc contains transparent and opaque sections (slots). As the motor turns, the disc chops the light beam into pulses. The photodetector receives these pulses and converts them into a square wave electrical signal.

The AGV's central computer (PLC or Microcontroller) counts these edges. By calculating the frequency of pulses, it determines speed. By counting the total number of pulses, it calculates distance traveled—a process known as Dead Reckoning.

Real-World Applications

Wheel Odometry

The primary source of truth for AGV localization. Encoders on drive wheels track distance traveled to calculate X/Y coordinates in a warehouse map.

Precision Steering

In tricycle or Ackermann steering configurations, absolute optical encoders ensure the drive wheel is oriented exactly at the commanded angle.

Lift Height Control

Used in automated forklifts and VNA (Very Narrow Aisle) trucks to position forks at exact racking heights for pallet retrieval.

LiDAR Rotation

Many spinning LiDAR sensors, essential for SLAM navigation, use internal optical encoders to synchronize the laser angle with the point cloud data.

Frequently Asked Questions

What is the main advantage of optical encoders over magnetic encoders?

Optical encoders generally offer significantly higher resolution and accuracy compared to magnetic versions. They are also completely immune to magnetic interference, which is crucial when mounting sensors directly onto high-power electric motors found in industrial AGVs.

Why do AGVs drift over time if they use encoders?

This is caused by accumulated error. Encoders measure wheel rotation, not actual ground movement. Factors like wheel slippage on smooth concrete, uneven floor surfaces, or tire wear cause the physical distance traveled to differ from the encoder count, requiring periodic recalibration via LiDAR or QR codes.

What is the difference between Single-turn and Multi-turn absolute encoders?

Single-turn encoders provide the absolute position within one 360-degree rotation, resetting after a full turn. Multi-turn encoders track the position within a rotation AND count the total number of full revolutions, retaining this data even after power loss, which is ideal for lift mechanisms.

How does dust affect optical encoders in a warehouse environment?

Because they rely on light transmission, optical encoders are susceptible to dust, oil, and moisture blocking the code disc. For harsh warehouse environments, it is critical to use encoders with a high IP rating (e.g., IP65 or IP67) that are sealed against contaminants.

What is the Index Channel (Z-channel)?

The Index or Z-channel produces a single pulse once per revolution. It is used in incremental encoders to establish a known "home" reference point. The robot can rotate the wheel until the index pulse is triggered to verify its mechanical zero position.

How do I choose the right resolution (CPR) for my robot?

Select a resolution that creates at least 4 to 10 pulses for the smallest movement increment you need to control. However, extremely high CPR requires higher frequency processing from your microcontroller; ensure your hardware bandwidth matches the encoder's output at max RPM.

Can optical encoders measure speed as well as position?

Yes. Position is measured by counting the accumulated pulses. Speed is measured by calculating the frequency of those pulses (pulses per second) or measuring the time duration between pulses. This dual capability makes them standard for PID motor control loops.

What are common output interfaces for optical encoders?

The most common for incremental encoders are TTL (Transistor-Transistor Logic) and HTL (High Threshold Logic/Push-Pull). For absolute encoders, serial protocols like SSI, BiSS-C, or fieldbuses like CANopen and EtherCAT are standard in industrial robotics.

Do optical encoders require maintenance?

The optical components themselves do not wear out, but the mechanical bearings supporting the shaft do. Maintenance typically involves checking the cable connections for fatigue and ensuring the shaft seals remain intact to prevent dust ingress.

How does vibration affect optical encoders?

Glass code discs can shatter under extreme shock, and excessive vibration can cause reading errors or bearing failure. For rugged AGVs operating on uneven floors, encoders with metal or unbreakable mylar discs and heavy-duty bearing assemblies are recommended.

What is Quadrature encoding?

Quadrature encoding uses two output channels (A and B) that are out of phase by 90 electrical degrees. By detecting which channel leads the other, the controller determines direction. By counting both the rising and falling edges of both channels, the effective resolution is quadrupled (x4 decoding).

Are optical encoders expensive compared to other sensors?

They are generally more expensive than potentiometers or basic magnetic sensors due to their complexity and precision manufacturing. However, the cost is justified in robotics where navigation accuracy directly impacts safety and efficiency.