Motion Profiling

Transform raw motor commands into fluid, kinematic precision. Motion profiling generates smooth velocity and acceleration curves to ensure your AGVs navigate dynamic environments with stability, efficiency, and pinpoint accuracy.

Core Concepts

Kinematic Constraints

Defining the physical limits of the robot, such as maximum velocity, acceleration, and deceleration, to prevent mechanical stress or loss of traction.

Trapezoidal Profile

The foundational velocity profile consisting of constant acceleration, constant cruising velocity, and constant deceleration for efficient point-to-point moves.

S-Curve Profiling

Advanced smoothing that limits "Jerk" (the rate of change of acceleration). Crucial for transporting fragile liquids or preventing wheel slip in heavy AGVs.

Feedforward Control

Predicting the required motor output based on the physics model rather than reacting to errors, resulting in near-zero lag during movement.

Time Discretization

Breaking down the desired path into millisecond-level setpoints that the motor controllers can execute in real-time control loops.

Multi-Axis Sync

Ensuring that linear movement and rotational movement (holonomic or differential) start and end precisely together for complex curves.

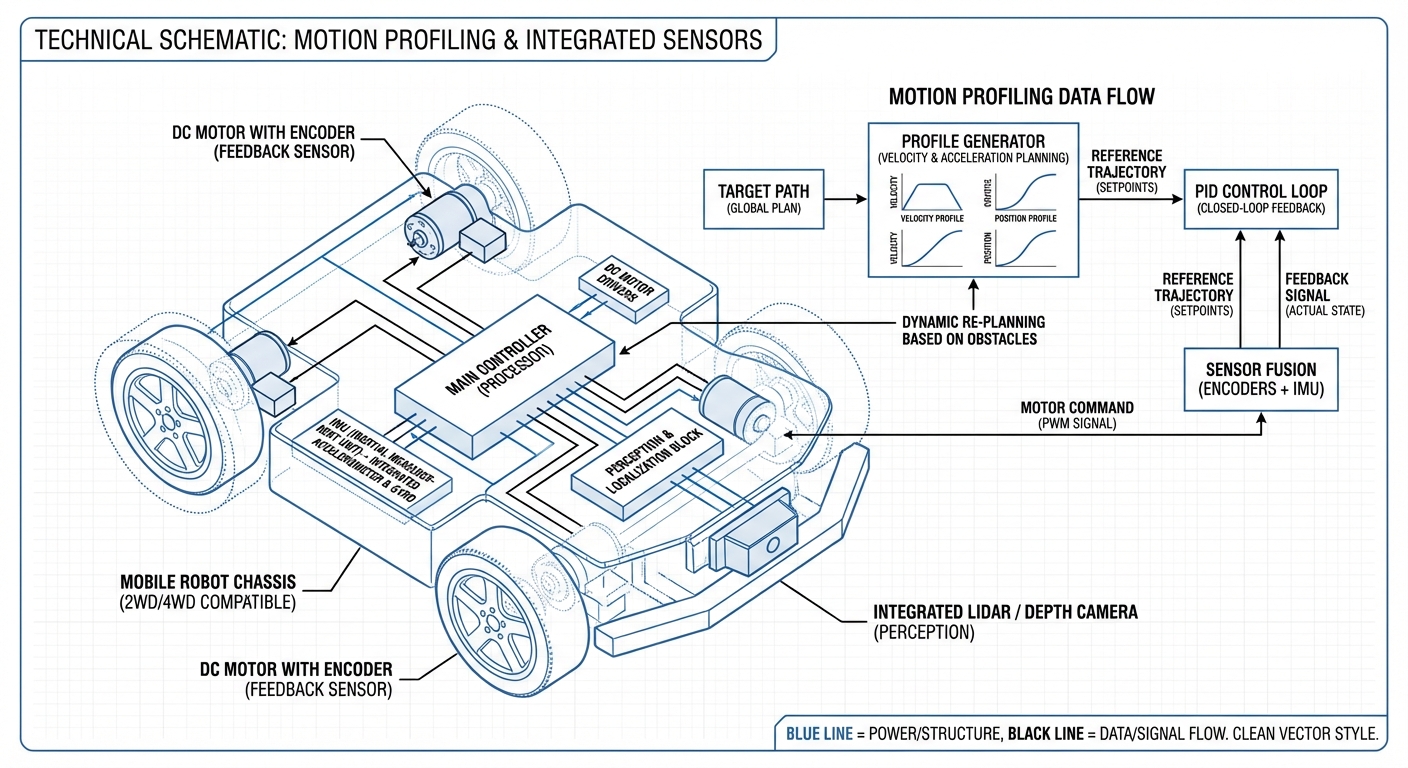

How It Works

At its core, motion profiling is a mathematical negotiation between what you want the robot to do and what physics allows it to do. Instead of simply telling a motor to go to position X, the profiler calculates the entire journey before the wheels even turn.

The system takes the target distance and applies constraints: maximum velocity (V-max), maximum acceleration (A-max), and maximum jerk (J-max). It then generates a stream of setpoints—typically every 10ms or 20ms—that define exactly where the robot should be at that specific moment in time.

These setpoints are fed into the PID controller. Because the trajectory is physically achievable, the error term remains minimal, resulting in exceptionally smooth motion that reduces battery consumption and mechanical wear on the AGV gearboxes.

Real-World Applications

High-Speed Intralogistics

In high-density warehouses, Kiva-style robots use trapezoidal profiling to maximize throughput. They accelerate aggressively to top speed on straightaways and decelerate precisely to pick stations, shaving milliseconds off every task.

Medical Transport

Hospital AGVs transporting blood samples or meals utilize S-Curve profiling. By limiting jerk, they ensure no spills or jarring movements occur, even when navigating around sudden obstacles in hallways.

Heavy Payload Manufacturing

AMRs moving multi-ton chassis in automotive plants rely on motion profiling to manage inertia. The profile calculates the extensive braking distance required, ensuring safety stops are smooth rather than catastrophic.

Precision Assembly

Robotic arms and mobile manipulators use synchronized multi-axis profiling to align parts with sub-millimeter accuracy, allowing for automated mating of components while the base is still settling.

Frequently Asked Questions

What is the difference between Motion Planning and Motion Profiling?

Motion Planning (or Path Planning) determines where to go to avoid obstacles (e.g., A* or RRT algorithms). Motion Profiling determines how to move along that path over time, calculating specific velocities and accelerations to ensure the movement is smooth and physically possible.

Why should I use S-Curve over Trapezoidal profiling?

Trapezoidal profiles have instant changes in acceleration, which causes infinite jerk. This can lead to wheel slip, mechanical vibration, and wear. S-Curve profiling ramps acceleration up and down smoothly, protecting the gearbox and improving traction, though it requires more complex computation.

How does payload weight affect motion profiling parameters?

Ideally, profiling parameters (max accel/decel) should be dynamic. A fully loaded AGV has higher inertia and requires lower acceleration limits and longer braking distances compared to an empty one. Advanced systems adjust these constraints in real-time based on current load estimation.

Does motion profiling replace PID control?

No, they work in tandem. Motion profiling provides the "Feedforward" reference—the ideal state the robot should be in. The PID controller works as "Feedback," correcting small errors caused by friction, gravity, or uneven terrain to keep the robot on the profiled path.

What hardware requirements are necessary for effective profiling?

You need high-resolution encoders for accurate position feedback and a microcontroller capable of floating-point math running a control loop of at least 50Hz-100Hz. Sluggish loops will result in "stair-stepped" motion rather than fluid movement.

How do you handle dynamic obstacles during a profile execution?

If an obstacle is detected, the profile must be interrupted. Usually, a separate "E-stop" or "fast-stop" profile is triggered immediately to decelerate the robot as fast as physically allowed. Once clear, a new profile is calculated from the current stopped position to the goal.

Can motion profiling help with battery life?

Yes, significantly. By avoiding current spikes associated with hard starts and stops, and by utilizing coasting periods effectively, motion profiling reduces thermal loss in motors and optimizes energy usage, extending fleet runtime per charge.

What is the "following error" and why is it important?

Following error is the difference between the profiled target position and the actual encoder position at any given moment. Monitoring this is critical; a large growing error usually indicates a mechanical stall, wheel slip, or that the profile constraints are too aggressive for the hardware.

Does this work with non-holonomic drives (like Ackerman steering)?

Yes, but the math is more complex. For Ackerman (car-like) steering, the profile must respect the minimum turning radius. The profiler generates a path (often splines) and derives the linear velocity and steering angle velocities required to follow that arc.

What is the impact of loop latency on motion profiling?

Latency is the enemy of smooth motion. If the command arrives late, the motor controller is acting on old data, causing oscillation. Deterministic communication protocols (like EtherCAT or CAN bus) are preferred to ensure profile setpoints arrive exactly when needed.