Modbus Protocol

The industrial standard connecting the world of mobile robotics. Modbus serves as the reliable communication backbone for AGV fleets, ensuring seamless data exchange between PLCs, sensors, and central fleet management systems to keep your operations moving.

Core Concepts

Client/Server Model

Formerly Master/Slave, this architecture dictates how data flows. The Fleet Manager (Client) requests status updates, and the AGV (Server) responds with position and battery data.

Modbus TCP/IP

The modern standard for robotics. It encapsulates Modbus frames inside TCP/IP packets, allowing AGVs to communicate over standard Wi-Fi networks with high reliability.

Registers & Coils

The internal data map. Coils represent binary states (stopped/moving), while Holding Registers store complex values like X/Y coordinates, speed, and payload weight.

Latency Management

Crucial for mobile robots. Modbus is lightweight, minimizing overhead to ensure near real-time instruction execution for safety-critical navigation.

Error Checking

Utilizes CRC (Cyclic Redundancy Check) to ensure data integrity. If an AGV receives a corrupted packet due to interference, it discards it to prevent erratic behavior.

Integration Ease

Open-source and universally supported. Modbus allows our robots to interface directly with existing warehouse infrastructure, elevators, and conveyor belts without proprietary gateways.

How It Works

In a typical mobile robotics environment, Modbus acts as the translation layer between the physical hardware and the logical control software. The process begins with the PLC or Fleet Server initiating a request frame addressed to a specific Robot ID.

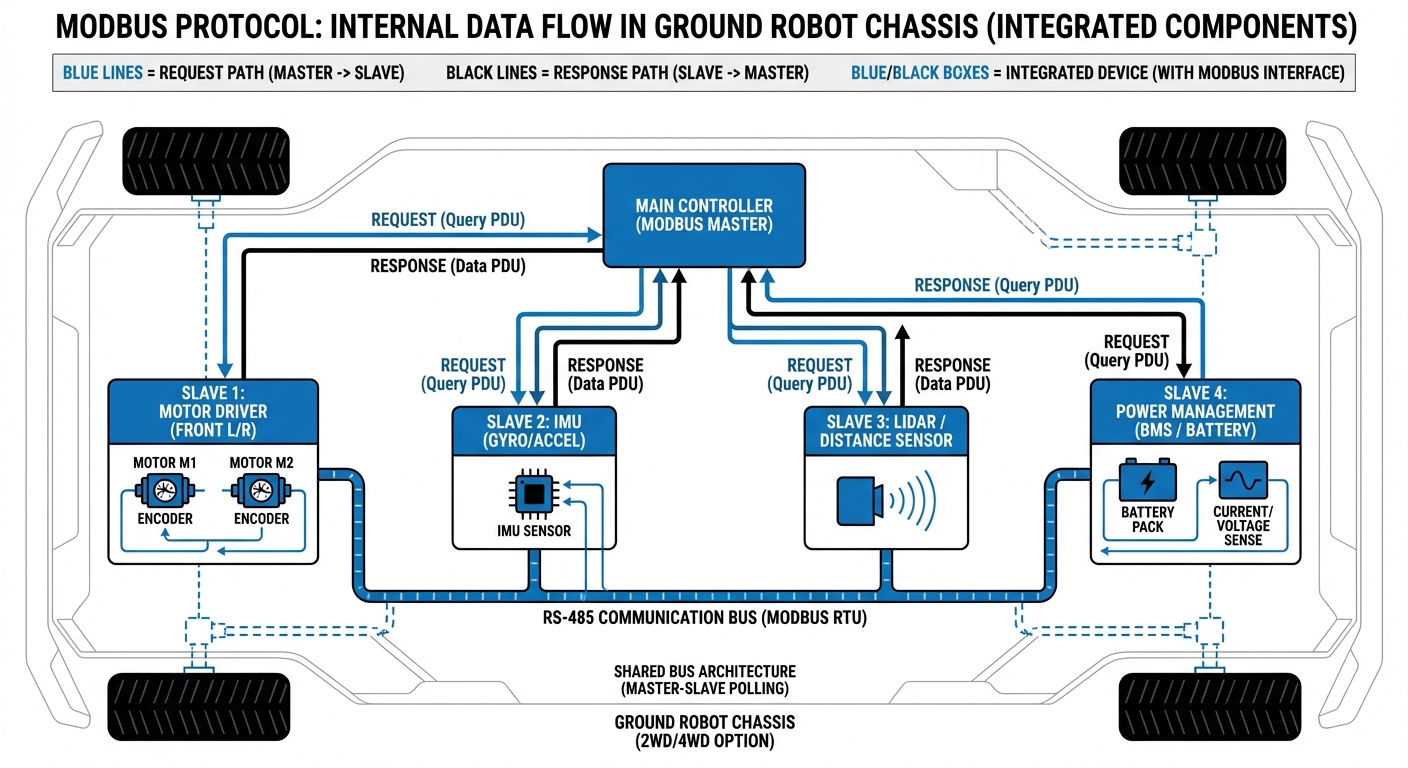

The targeted AGV receives this request via TCP/IP (over Wi-Fi) or RTU (over RS485 for internal components). It parses the function code—such as "Read Holding Registers"—to determine if the controller wants to know the current battery percentage or the error status.

Finally, the robot responds with the requested data. This cycle happens milliseconds apart, creating a continuous loop of feedback and control that allows for precise fleet coordination and immediate reaction to environmental changes.

Real-World Applications

Facility Integration

AGVs use Modbus to "talk" to automatic doors and elevators. When a robot approaches a door, it writes a '1' to a specific coil address to trigger the door opening mechanism, ensuring seamless transit.

Battery Management Systems (BMS)

Internal communication often relies on Modbus RTU to monitor cell voltages and temperatures. The AGV controller reads these registers to determine when to autonomously return to a charging station.

Production Line Handshakes

In manufacturing, conveyor belts communicate with AGVs via Modbus. The belt signals it is 'Ready to Unload', and the robot confirms 'In Position' before physical transfer occurs.

Hybrid Fleet Orchestration

Modbus provides a common denominator allowing different brands of robots and PLCs to coexist. A central VDA 5050 compliant system often uses Modbus wrappers to command diverse hardware.

Frequently Asked Questions

What is the difference between Modbus RTU and Modbus TCP for AGVs?

Modbus RTU uses serial communication (RS-232 or RS-485) and is typically used for internal robot components like motor drivers or sensors. Modbus TCP encapsulates the data in Ethernet packets, making it ideal for wireless communication between the AGV and the central fleet management server.

Why is Modbus still used in modern robotics instead of newer protocols like MQTT?

While MQTT is great for cloud connectivity, Modbus remains the industry standard for local, real-time control due to its simplicity, lack of overhead, and massive support across legacy industrial hardware like PLCs and door controllers found in warehouses.

How does an AGV handle Modbus communication loss?

Safety is paramount. If the "heartbeat" signal (a constantly changing register value) from the Fleet Manager stops updating via Modbus for a set threshold (e.g., 500ms), the AGV is programmed to trigger an immediate E-Stop or enter a safe, idle state.

What is the maximum number of AGVs manageable via Modbus?

Technically, Modbus allows for up to 247 device addresses per network segment. However, in a TCP/IP environment, the limit is defined by network bandwidth and server processing power, allowing for fleets of hundreds of robots if the network architecture is robust.

Can Modbus transmit video or mapping data?

No. Modbus is designed for control data (bits and integers) not large BLOBs. High-bandwidth data like LIDAR point clouds or camera feeds are typically transmitted via ROS topics or separate HTTP/RTSP streams, while Modbus handles the movement logic.

How secure is Modbus for industrial robots?

Standard Modbus lacks native encryption or authentication. For secure AGV deployments, we recommend tunneling Modbus TCP through a VPN, using VLANs to isolate robot traffic, or implementing Modbus Security (a newer secure variation of the protocol).

What are the typical hardware requirements to implement Modbus on a robot?

Minimal requirements. Any microcontroller (Arduino, ESP32) or industrial computer (Raspberry Pi, IPC) with a serial port or Ethernet interface can implement Modbus. Most industrial PLCs support it out of the box.

How do we map AGV functions to Modbus registers?

This is defined in the robot's Interface Control Document (ICD). Typically, registers 40001-40010 might hold X/Y coordinates, 40011 might be battery level, and Coils 0001-0005 might control simple actions like "Lift Up" or "Reset Alarm."

Is Modbus affected by electrical noise in factories?

Modbus RTU over RS-485 is highly resistant to noise due to differential signaling. However, proper shielding and grounding are essential in environments with high-voltage motors to prevent packet corruption.

Can we control AGV speed dynamically via Modbus?

Yes. A specific Holding Register is usually designated for "Target Speed." Writing an integer value (e.g., 50 for 0.5m/s) to this register allows the central system to slow down robots in high-traffic zones dynamically.

What is the typical polling rate for an AGV fleet?

For navigation and traffic control, a polling rate between 10Hz and 20Hz (every 50-100ms) is standard. This provides a balance between network load and the granularity required for smooth motion control.

How do I troubleshoot a Modbus connection failure?

Start by verifying IP connectivity (ping). Then use a Modbus Scanner software to attempt to read a known register. Check for common issues like mismatched Slave IDs, incorrect baud rates (for RTU), or firewall ports (Port 502) being blocked.