Magnetic Encoders

The robust heartbeat of modern mobile robotics. Magnetic encoders deliver precise positioning and velocity feedback for AGVs, thriving in harsh environments where optical sensors fail.

Core Concepts

Hall Effect Principle

Utilizes Hall Effect sensors to detect changes in magnetic fields generated by a rotating magnet. This non-contact method converts magnetic flux into voltage signals for position data.

High Durability

Unlike optical encoders, magnetic variants are impervious to dust, oil, moisture, and vibration. This makes them ideal for AGVs operating in warehouses or outdoor terrain.

Absolute vs. Incremental

Magnetic encoders come in incremental (relative change) or absolute (exact position) types. Absolute encoders retain position data even after power loss, critical for safety-rated robots.

Compact Form Factor

The sensor chip and magnet assembly take up significantly less space than optical disks. This allows for tighter integration into micro-motors and slim AGV chassis designs.

Resolution Flexibility

Modern magnetic encoders offer programmable resolution. You can adjust the Pulses Per Revolution (PPR) via software to balance processing speed with positional accuracy.

Cost-Efficiency

Generally more affordable than high-end optical solutions while providing sufficient accuracy for wheel odometry and lift mechanisms in most logistics applications.

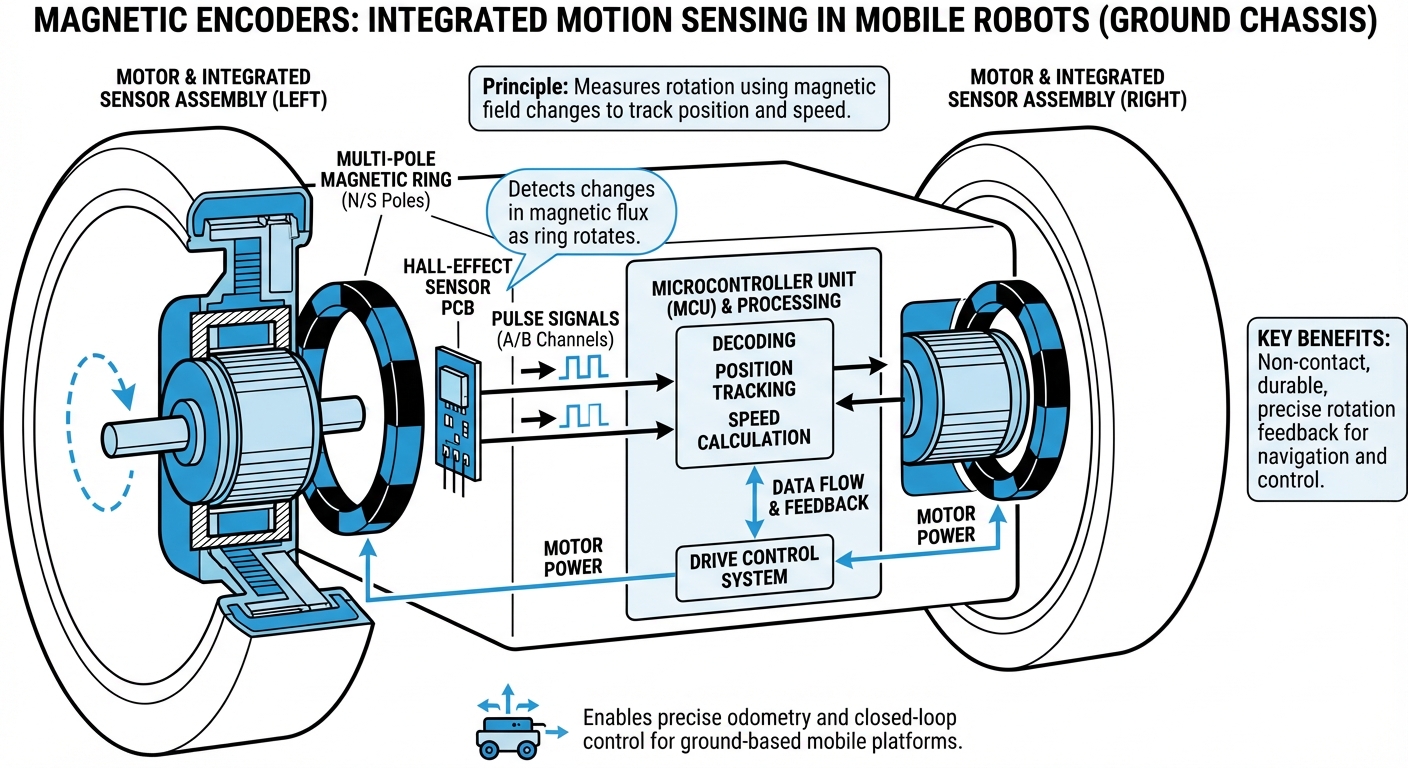

How It Works

The architecture of a magnetic encoder is deceptively simple yet highly effective. It consists of two primary components: a magnetized rotor (attached to the rotating shaft) and a sensor IC (fixed to the housing).

As the AGV motor spins, the rotor creates a rotating magnetic field. The Hall Effect or Magnetoresistive sensor detects the vector direction of this field. An internal processor instantly converts this sine/cosine analog signal into a digital output—typically quadrature pulses (A/B) or a digital protocol like SSI or BiSS.

Because there is no physical contact between the sensor and the magnet, and no reliance on light transmission, the system remains accurate even if the gap is filled with hydraulic fluid, grease, or dust.

Real-World Applications

Warehouse AMRs

Used in wheel odometry to calculate distance traveled and rotation angle. Magnetic encoders resist the cardboard dust and debris common in fulfillment centers.

Heavy-Duty Forklifts

Essential for steering angle feedback and lift-height positioning. Their vibration resistance ensures reliability on uneven concrete floors.

Outdoor Agriculture Robots

Sealed magnetic encoders (IP67+) are standard for ag-bots exposed to rain, mud, and fertilizers where optical seals would eventually fail.

Medical Transport Carts

Their silent operation and compact size allow for integration into hospital delivery robots navigating narrow corridors and patient rooms.

Frequently Asked Questions

What is the main advantage of magnetic encoders over optical encoders?

The primary advantage is environmental robustness. Magnetic encoders are immune to contaminants like oil, grease, water, and dust that can obscure the code disc in optical encoders. They are also generally more resistant to shock and vibration.

Can external magnetic fields interfere with the encoder's accuracy?

Yes, strong external magnetic fields (like those from large electric motor brakes) can interfere. However, modern magnetic encoders often feature differential sensing and shielding to mitigate this. Proper placement and magnetic shielding are recommended in high-EMI environments.

What is the typical resolution limit of a magnetic encoder?

While historically lower than optical, modern magnetic encoders can achieve resolutions up to 16-18 bits (over 200,000 counts per revolution). This is more than sufficient for the vast majority of AGV wheel odometry and joint control applications.

Do I need an absolute or incremental encoder for my AGV?

For wheel velocity, incremental is usually sufficient. However, for steering angle or robotic arms, absolute encoders are preferred because they know their exact position immediately upon startup without needing a homing sequence.

How critical is the alignment between the magnet and the sensor?

Magnetic encoders are generally more forgiving of axial and radial misalignment than optical ones. However, adhering to the manufacturer's specified air gap (distance between magnet and chip) is critical for maintaining signal linearity and resolution.

Are magnetic encoders suitable for high-speed motors?

Yes, many magnetic encoders support very high RPMs (often exceeding 10,000 RPM) because there are no contacting parts or glass discs to shatter. Latency is the main factor to check; ensure the sensor's bandwidth matches your control loop speed.

How does temperature affect magnetic encoder performance?

Magnetic field strength changes with temperature. However, high-quality encoders have internal temperature compensation logic. They typically operate reliably across a wide range (-40°C to +125°C), making them great for cold storage AGVs.

What are the maintenance requirements?

They are virtually maintenance-free. Since there is no physical contact (no bearings inside the encoder itself for kit encoders) and no LED to burn out, they often outlast the motors they are attached to.

Can I retrofit an optical encoder with a magnetic one?

Often yes, provided the mounting footprint and shaft diameter match. You must also ensure the output signal type (e.g., TTL Quadrature, RS422) and voltage are compatible with your existing motor controller.

What is "On-Axis" vs. "Off-Axis" mounting?

On-Axis places the magnet on the end of the shaft, directly facing the sensor. Off-Axis (or hollow shaft) uses a ring magnet, allowing the shaft to pass through. Off-axis is useful when the shaft end is not available or for large diameter joints.

How does the cost compare to optical encoders?

For standard resolutions, magnetic encoders are usually cheaper to manufacture and assemble. High-precision optical encoders are significantly more expensive but are only necessary for applications requiring nanometer-level precision.

What communication interfaces are common for AGVs?

For basic motor control, ABZ quadrature is standard. For advanced AGVs requiring absolute positioning and diagnostics, digital protocols like SSI, BiSS-C, or CANopen are widely used.