Linear Actuators

The muscle behind modern automation, linear actuators convert electrical energy into precise straight-line motion. Essential for AGV lifting mechanisms, automatic hitching, and material handling, they provide the push-and-pull force that drives logistics forward.

Core Concepts

Stroke Length

The distance the rod travels from fully retracted to fully extended. In AGVs, this determines lifting height or latching reach.

Load Capacity

Defined as Static (holding) and Dynamic (moving) load. Crucial for ensuring the actuator can lift the payload without stalling.

Speed vs. Force

There is an inverse relationship between speed and force. Higher gear ratios provide more lifting power but slower movement speeds.

Duty Cycle

The percentage of time an actuator can run without overheating. Essential calculation for high-frequency warehouse operations.

IP Rating

Ingress Protection levels indicate resistance to dust and liquids. IP66+ is standard for wash-down food automation or dirty floors.

Feedback Sensors

Hall effect sensors or potentiometers provide positional data to the controller, allowing for synchronized movement and precision stops.

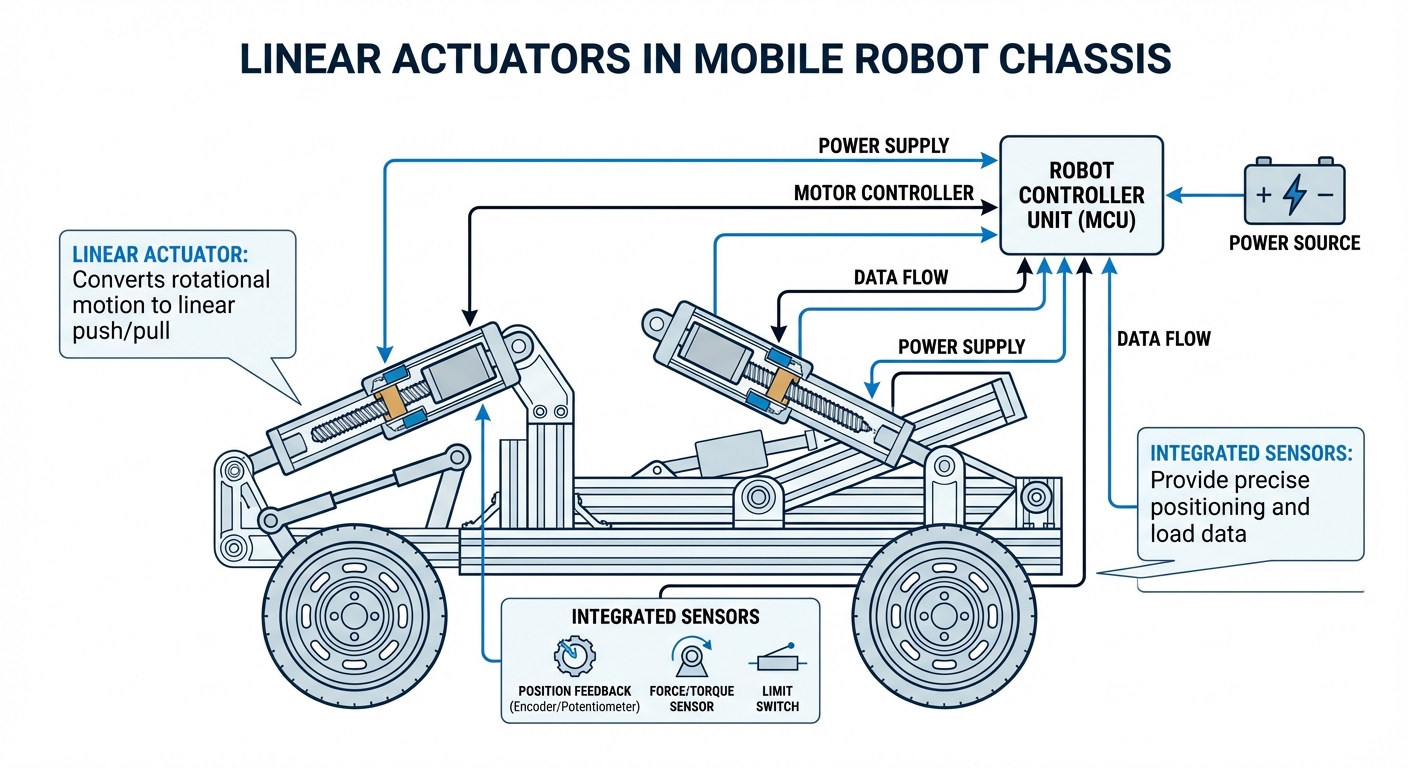

How It Works

At the heart of an electric linear actuator is a DC motor (brushed or brushless) connected to a gearbox. This gearbox reduces speed while increasing torque, rotating a lead screw or ball screw mechanism.

As the screw turns, a drive nut—which is mechanically prevented from rotating—is forced to move linearly along the threads. This pushes the extension tube out or pulls it back in.

For AGVs, this mechanism is superior to hydraulics because it requires no fluids, pumps, or hoses, offering a "clean" actuation method that is easily integrated into the robot's existing electrical system (typically 24V or 48V).

Real-World Applications

Underride AGV Lifting

The most common use case. An AGV slides under a cart, and linear actuators raise a lifting plate to engage the cart's frame, lifting the wheels off the ground for transport.

Automatic Hitching

Used in tugger AGVs to automatically couple and decouple trailers. A linear actuator drives a locking pin up or down into the trailer's tow bar loop.

Variable Height Conveyors

Mobile robots with top modules that need to align with various factory stations. Actuators adjust the conveyor deck height to match the input/output ports of CNC machines.

Battery Exchange Mechanisms

In automated battery swapping stations, heavy-duty actuators push depleted batteries out of the AGV chassis and pull fresh batteries into place.

Frequently Asked Questions

What is the difference between a Lead Screw and a Ball Screw actuator?

Lead screws use sliding friction and are quieter, self-locking, and cheaper, but less efficient. Ball screws use rolling ball bearings, offering high efficiency, higher speeds, and longer life, but they generally require a brake to hold position when power is off.

Does an AGV linear actuator need a brake?

It depends on the screw type and pitch. Many lead screw actuators are "self-locking," meaning the load cannot back-drive the motor when power is cut. However, for safety in vertical lifting applications or when using high-efficiency ball screws, an electromechanical brake is mandatory to prevent dropping the load.

How do I synchronize two actuators to lift a platform evenly?

You need actuators equipped with feedback sensors (Hall effect or Potentiometer). A dedicated controller reads the position pulses from both units simultaneously and adjusts the voltage (speed) of the faster unit to match the slower one, ensuring the platform remains level.

What voltage should I choose for my mobile robot?

Most industrial AGVs run on 24V DC or 48V DC bus architectures. It is best to match the actuator voltage to your battery system to avoid the inefficiency and cost of DC-DC converters. 12V is common in automotive but less common in heavy-duty industrial robotics.

What is the typical duty cycle for an electric actuator?

Standard industrial actuators usually have a duty cycle around 10% to 25% at full load. This means if it runs for 1 minute, it needs 4 to 9 minutes of rest to cool down. For high-throughput logistics, you must oversize the actuator or select specialized high-duty cycle models.

How does temperature affect actuator performance?

Extreme cold can thicken the grease, increasing resistance and amp draw, potentially triggering over-current protection. Extreme heat reduces the allowable duty cycle. For cold storage warehouses, specify low-temperature lubricants during procurement.

Can linear actuators be used outdoors?

Yes, but IP rating is critical. Look for IP66 (powerful water jets) or IP69K (high-pressure/steam cleaning). Additionally, the housing material should be corrosion-resistant (e.g., stainless steel or powder-coated aluminum) if exposed to rain or saline environments.

What happens if the actuator hits an obstruction?

Without protection, the motor will stall, current will spike, and it may burn out or strip gears. Modern implementations use a controller with "Over Current Protection" (OCP) that cuts power immediately if the current exceeds a set threshold, acting as an electronic clutch.

How accurate is the positioning?

With a Hall effect sensor, accuracy is typically tied to the gear and screw pitch, often within 0.5mm to 1mm. For ultra-high precision applications (e.g., optical alignment), stepper motor actuators or linear servos are required.

Why are electric actuators preferred over hydraulic for AGVs?

Hydraulics are messy (leaks), require maintenance (fluid changes), and are energy inefficient because the pump runs constantly. Electric actuators draw power only when moving, offer cleaner operation, and provide easier digital feedback for automation systems.