IP Ratings and Waterproofing

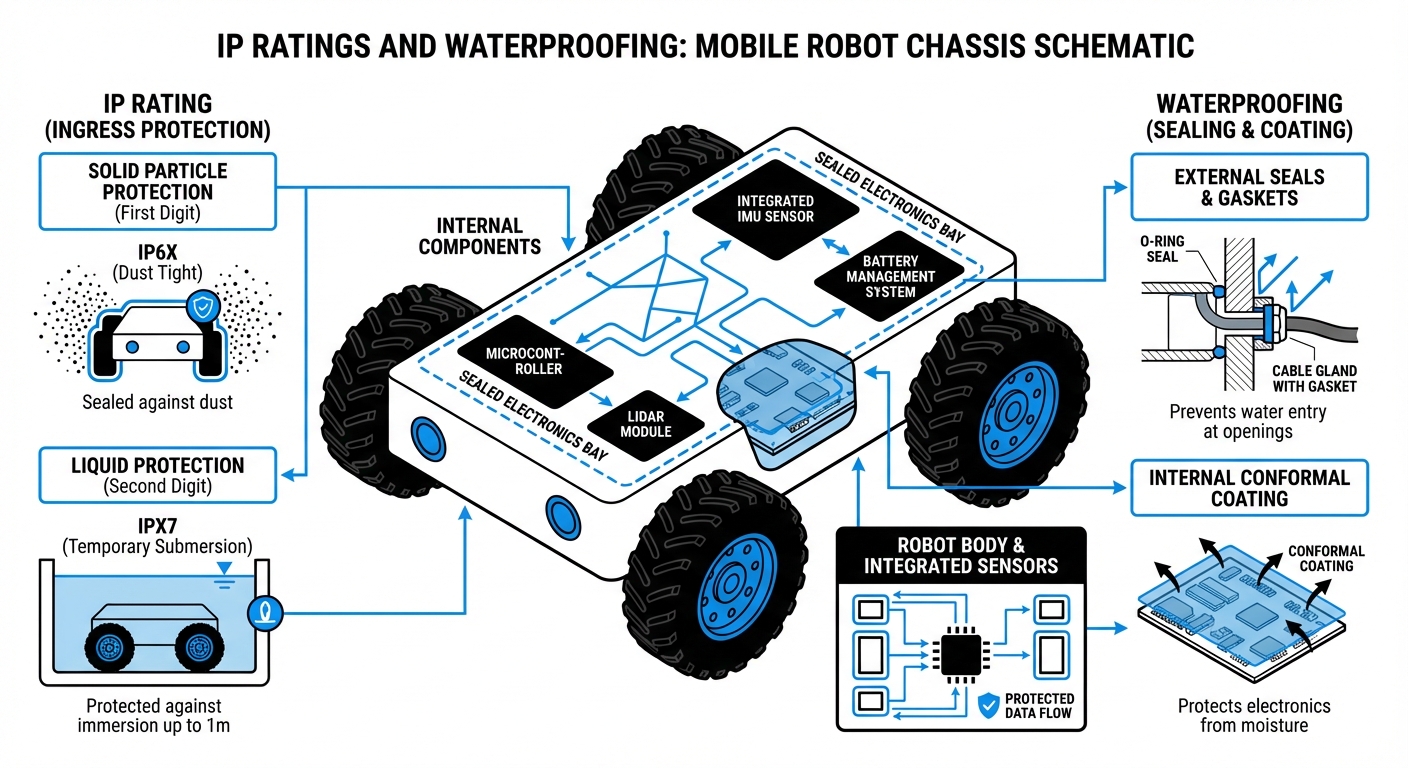

Ingress Protection (IP) ratings define the durability of autonomous mobile robots against dust and moisture intrusion. Understanding these standards is critical for ensuring fleet reliability in harsh industrial environments, from washdown-ready food plants to dusty construction sites.

Core Concepts

The First Digit (Solids)

The first number in an IP code (e.g., the '6' in IP65) indicates protection against solid objects. Scale ranges from 0 (no protection) to 6 (dust-tight), crucial for environments with metal shavings or flour.

The Second Digit (Liquids)

The second number (e.g., the '5' in IP65) measures water resistance. It ranges from 0 to 9K, covering everything from light dripping condensation to high-pressure, high-temperature washdowns.

Sealing Engineering

Waterproofing isn't just about the shell. It involves complex gasketing, O-rings, and potting compounds to protect PCBs and sensors while allowing for heat dissipation.

IP54 vs IP65

The most common distinction in robotics. IP54 handles general warehouse dust and splashes. IP65 is required for environments where robots may be sprayed with water jets or operate outdoors.

IP69K (Hygienic)

The gold standard for food and pharmaceutical robotics. This rating certifies that the robot can withstand close-range, high-pressure, high-temperature spray-downs necessary for sanitation.

Condensation Control

A sealed robot moving from cold storage to a warm dock creates internal condensation. Advanced IP designs include Gore-Tex® style vents to equalize pressure without letting water in.

How It Works: The Anatomy of Protection

Achieving a high IP rating in robotics is a balancing act between protection and performance. Unlike static machinery, AGVs have moving wheels, LiDAR sensors, and charging contacts that must be exposed to the world while protecting the delicate internal electronics.

Engineers utilize a "defense in depth" strategy. The outer chassis provides the first layer of defense against large debris. Inside, sensitive components like the CPU and battery management system are often housed in secondary sealed enclosures (IP67) or coated with conformal sprays to prevent short circuits from humidity.

Thermal management becomes the primary challenge. Because fans introduce dust and moisture, high-IP robots typically rely on passive cooling through the chassis (heatsinks) or liquid cooling loops, ensuring the robot remains sealed while dissipating heat generated by the drive motors.

Real-World Applications

Food & Beverage Processing

Robots in meat or dairy processing must withstand nightly chemical washdowns. These environments require IP69K ratings and stainless steel construction to prevent rust and bacterial growth.

Outdoor Logistics Yards

AMRs operating between buildings encounter rain, puddles, and snow. IP65 or IP67 ratings are essential to prevent water ingress into the wheel motors and battery compartments during transit.

Heavy Manufacturing

CNC machine tending involves exposure to cutting fluids and fine metal dust. High protection against solids (First digit 6) prevents conductive dust from shorting out the robot's logic boards.

Commercial Cleaning

Cleaning robots literally carry water tanks. They require robust internal sealing to ensure that leaks from their own payload do not damage their navigation systems or drive trains.

Frequently Asked Questions

What is the minimum IP rating recommended for a standard warehouse AGV?

For clean, indoor warehousing environments, IP54 is generally the industry standard. This protects against dust accumulation that could cause overheating and incidental splashes of water. If the warehouse floors are frequently scrubbed with wet industrial cleaners, IP54 is the minimum safe baseline.

Does IP67 mean my robot can work underwater?

Technically, IP67 means the device can withstand submersion in 1 meter of water for 30 minutes. However, AGVs are rarely designed for operation while submerged. This rating is intended to protect the robot if it accidentally drives through a deep puddle or falls into a drainage ditch, allowing for recovery without total electronic failure.

How does a high IP rating affect the cost of a robot?

High IP ratings (IP65+) significantly increase manufacturing costs due to the need for precision machined seals, waterproof connectors, and fan-less thermal designs. Expect a 15-30% premium for washdown-ready robots compared to their standard IP20 or IP54 counterparts.

Can I upgrade the IP rating of an existing robot?

Generally, no. IP ratings are determined by the fundamental chassis design and thermal architecture. Adding external seals to a robot designed for airflow cooling will likely cause it to overheat. Waterproofing must be engineered from the ground up.

How do LiDAR and camera sensors handle water droplets?

Even if the sensor housing is waterproof, water droplets on the lens can diffract light, blinding LiDAR or confusing cameras. Outdoor robots often require specific software filters to ignore rain or physical wipers/air jets to keep sensor lenses clear during operation.

What is the difference between NEMA ratings and IP ratings?

IP ratings (IEC standard) strictly cover dust and water ingress. NEMA ratings (US standard) cover those plus other hazards like corrosion (rust), icing, and oil coolants. For example, NEMA 4X is roughly equivalent to IP66 but also requires corrosion resistance.

Do IP ratings degrade over time?

Yes. Rubber gaskets dry out, O-rings crack, and seals loosen due to vibration from movement. Regular maintenance schedules for AGVs should always include inspecting seals and potentially re-testing waterproofing if the robot operates in critical wet environments.

Why are charging contacts a weak point for waterproofing?

Automatic charging requires exposed conductive metal plates. In wet environments, these can corrode or short. High-IP robots often use Wireless Inductive Charging to eliminate exposed contacts entirely, maintaining a fully sealed chassis.

What is the risk of condensation in cold chain robotics?

When a robot leaves a -20°C freezer into a humid loading dock, air inside the robot contracts and sucks in moisture, which condenses on electronics. Robots for cold chain require vacuum-sealed compartments, nitrogen purging, or active internal heating elements.

Is IP20 ever acceptable for an industrial robot?

IP20 offers finger protection but no dust or water protection. It is only acceptable for laboratory settings or strictly controlled clean manufacturing zones where temperature and humidity are constant and dust is non-existent. It is risky for general industry.