I2C Interface

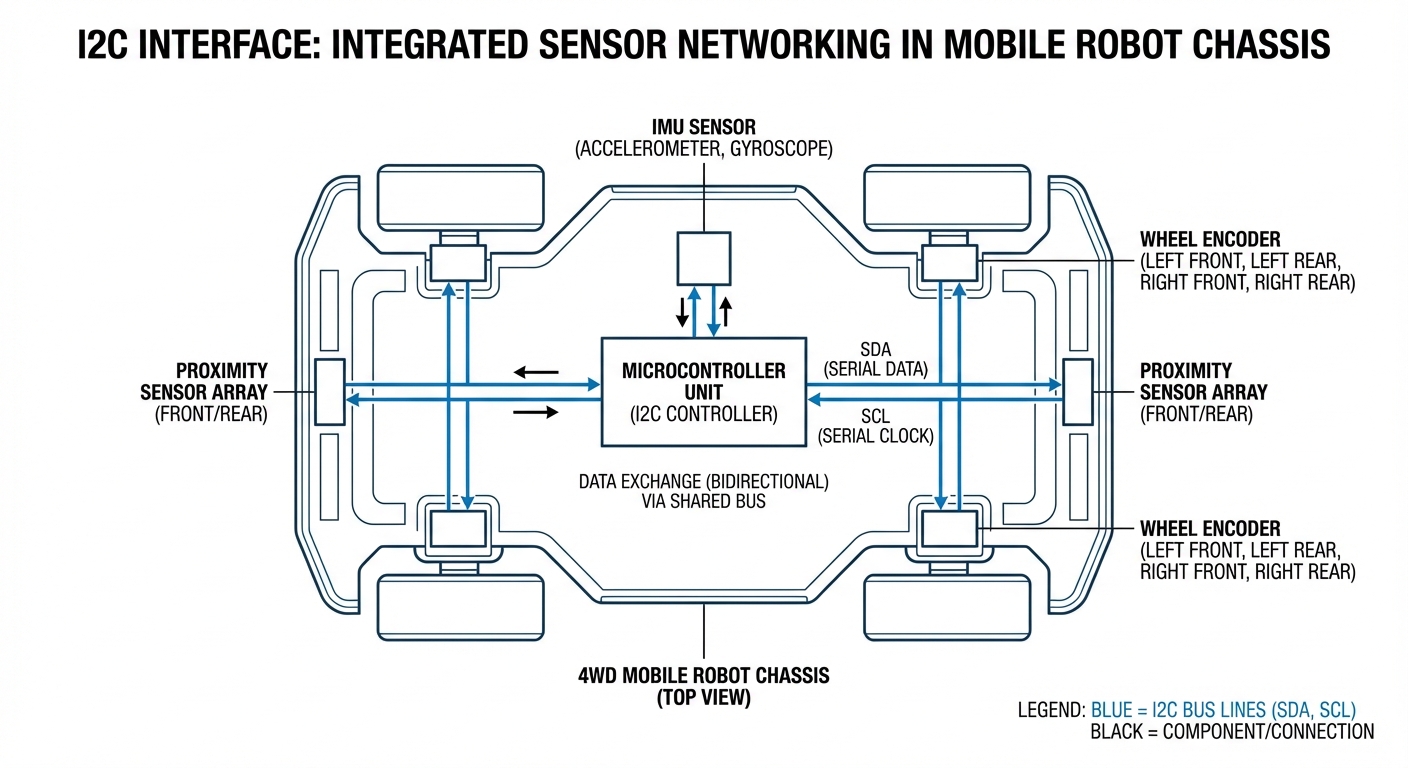

The Inter-Integrated Circuit (I2C) protocol is the backbone of internal communication within modern AGVs. It enables seamless, synchronized data exchange between microcontrollers and a vast array of sensors using just two wires, significantly reducing cabling complexity in mobile robots.

Core Concepts

Master-Slave Architecture

One device (the Master/Controller) initiates all communication, controlling the clock and data flow to various Slave devices (sensors/drivers).

SDA & SCL Lines

Uses only two active wires: Serial Data (SDA) for bidirectional information transfer and Serial Clock (SCL) to synchronize the bit timing.

Unique Addressing

Every device on the bus has a unique 7-bit or 10-bit address, allowing up to 127 devices to coexist on the same pair of wires without signal collision.

Synchronous Protocol

Unlike UART, I2C is synchronous. The output of bits is tied directly to the clock signal generated by the master, ensuring data integrity.

Open-Drain Design

The lines are "open-drain," meaning devices pull the line low to signal 0 and let it float high for 1. This prevents short circuits if two devices speak at once.

Multi-Master Support

Advanced implementations allow multiple masters on a single bus, enabling complex robotic architectures where different CPUs share access to sensors.

How It Works

At the hardware level, I2C requires two pull-up resistors to keep the lines high when idle. Communication begins when the Master pulls the SDA line low while SCL remains high—this is the unique "Start Condition" that alerts all devices on the bus to listen.

The Master then sends the 7-bit address of the target sensor followed by a Read/Write bit. Every byte sent is followed by an Acknowledge (ACK) bit from the receiver. If an AGV's main computer wants to read from a gyroscope, it addresses the gyroscope, sends the register address, and the gyroscope replies with the data.

This transaction concludes with a "Stop Condition" (SDA rising while SCL is high). Because of this strict framing, I2C is incredibly reliable for on-board diagnostics and configuring peripheral modules within the robot's chassis.

Real-World Applications

IMU & Navigation

I2C is the standard interface for Inertial Measurement Units (Accelerometers/Gyroscopes). AGVs rely on high-speed I2C (400kHz+) to poll orientation data for dead-reckoning navigation.

Battery Management Systems (BMS)

Smart battery packs use I2C (often the SMBus variant) to report state-of-charge, voltage, and temperature health data back to the main robot controller.

Environmental Sensing

Internal temperature sensors, humidity monitors, and ultrasonic proximity sensors typically utilize I2C, allowing a single microcontroller to monitor the robot's physical health.

OLED & LCD Displays

Small diagnostic screens mounted on the AGV exterior for human operators often run over I2C, reducing the number of wires running through the chassis hinge.

Frequently Asked Questions

What is the maximum distance for an I2C bus on an AGV?

I2C is designed for short-distance, inter-board communication, typically less than 1 meter. In robotics, if you need to run signals across a large chassis (over 1-2 meters), bus capacitance becomes an issue, degrading the signal. For longer distances, use active I2C buffers or switch to differential signaling (CAN bus or RS485).

How does I2C compare to SPI for robot sensors?

I2C uses only 2 wires regardless of the device count, making it simpler to wire, but it is generally slower (Standard 100kHz, Fast 400kHz). SPI is much faster (MHz range) and better for high-bandwidth data like cameras, but it requires 4 wires plus a dedicated "Chip Select" line for every single device, which complicates wiring harnesses.

What happens if two devices have the same I2C address?

This creates a bus conflict where both devices try to answer simultaneously, resulting in corrupted data. To solve this, you can use an I2C Multiplexer (like the TCA9548A) to create separate channels, or change the address of one device using its hardware address pins (if available).

Why do I need pull-up resistors?

I2C devices are "open-drain," meaning they can pull a line to Ground but cannot drive it High to VCC. External resistors (typically 4.7kΩ or 10kΩ) are required to pull the lines back up to the voltage logic level (3.3V or 5V) when no device is transmitting a zero.

Can I mix 3.3V and 5V devices on the same I2C bus?

Not directly without risk. Connecting a 5V device to a 3.3V microcontroller can damage the controller. You should use a Bi-Directional Logic Level Converter (LLC) to safely bridge the two voltage domains while maintaining the bidirectional nature of the I2C protocol.

Is I2C susceptible to motor noise in AGVs?

Yes, because it is a single-ended signal, I2C can be affected by electromagnetic interference (EMI) from high-power motors. To mitigate this, keep I2C wires short, twist the SDA/SCL lines with ground wires, use shielded cables, and keep them physically distant from motor power lines.

What is "Clock Stretching"?

Clock stretching allows a slower slave device to hold the SCL line low, forcing the master to wait before sending more data. This is useful for sensors that need time to process a reading, though not all master controllers support this feature properly.

How many devices can I actually connect?

Theoretically 127 (using 7-bit addressing). Practically, you are limited by the total bus capacitance (400pF max). As you add more devices, the capacitance increases, making the signal edges "soft," which causes communication errors. In most AGVs, 5-10 devices per bus is a practical safe limit.

How do I troubleshoot a locked-up I2C bus?

A common issue is a slave device getting stuck holding SDA low. You can attempt to clear this by toggling the SCL line manually 9 times to flush the bits, or by power cycling the sensors. Using an oscilloscope or logic analyzer is the best way to visualize if a line is stuck low.

Is I2C hot-swappable?

Standard I2C is not hot-swappable. Plugging a sensor in while the system is running can cause glitches on the bus lines that confuse other devices or the master. Special I2C buffers with hot-swap capabilities exist if this feature is required for modular tool-changing robots.

What is the "Repeated Start" condition?

A Repeated Start is used when the Master wants to switch from writing to reading (or vice versa) without releasing the bus to other masters. This is critical in multi-master environments to ensure an atomic operation, like reading a sensor register immediately after selecting it.

What tools can I use to debug I2C on a Linux-based AGV?

On Linux (like a Raspberry Pi or Nvidia Jetson), the `i2c-tools` package is essential. Commands like `i2cdetect` allow you to scan the bus for active addresses, while `i2cget` and `i2cset` let you manually read and write registers for testing connectivity.