Harmonic Drives

Unlock unparalleled precision in mobile robotics with strain wave gearing technology. Harmonic drives deliver the high torque density and zero backlash essential for the accurate navigation and manipulation capabilities of modern AGVs.

Core Concepts

Zero Backlash

Unlike planetary gears, harmonic drives operate with zero mechanical play. This ensures that AGV steering and manipulator arms maintain exact positioning without "slop" or jitter.

High Torque Density

These drives transmit massive torque relative to their physical size and weight. This allows compact AGV designs to lift heavy payloads without requiring bulky transmission systems.

High Reduction Ratios

Achieve reduction ratios from 30:1 to 320:1 in a single stage. This eliminates the need for complex, multi-stage gearboxes, reducing failure points and maintenance needs.

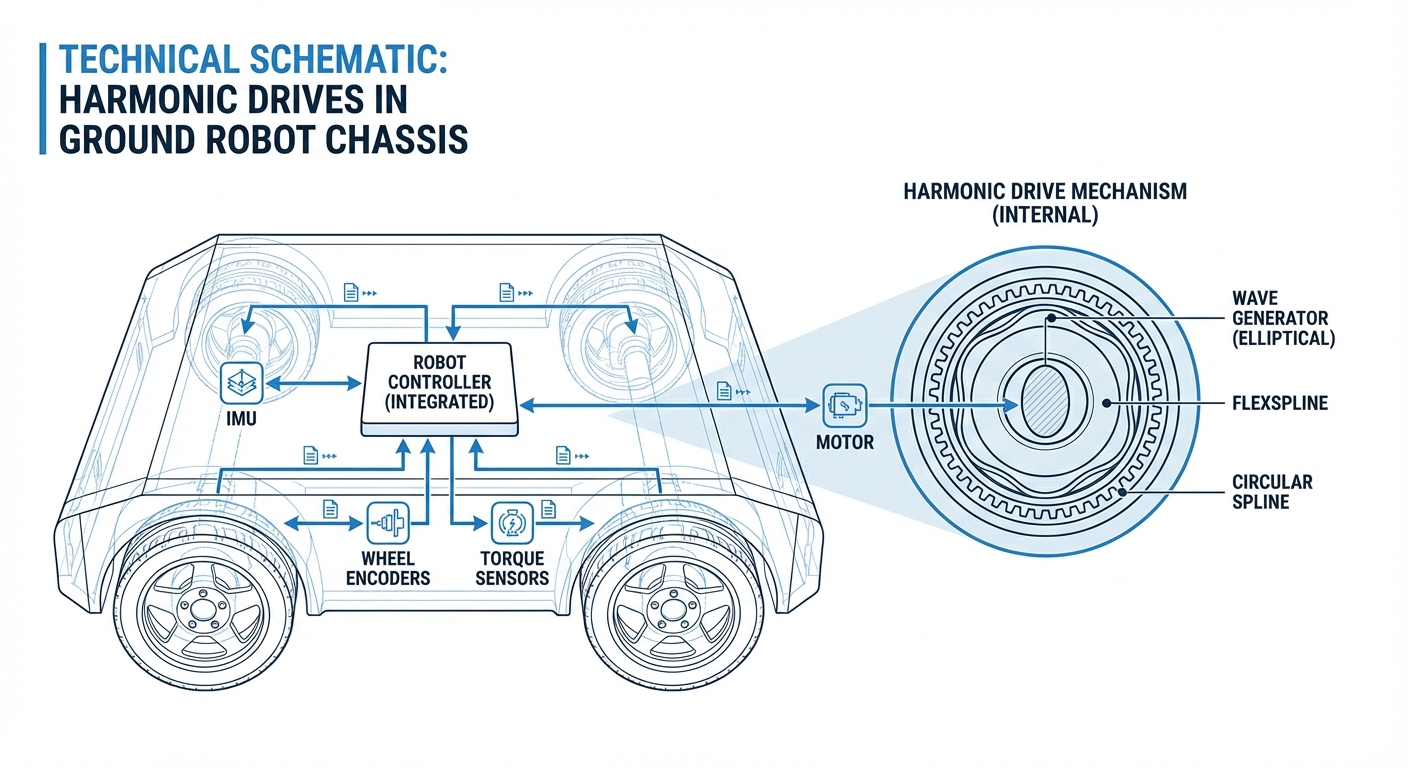

The Three Components

Comprised of just three parts: the Wave Generator (input), the Flexspline (flexible cup), and the Circular Spline (outer ring). Simple architecture leads to high reliability.

Positional Accuracy

Because approximately 30% of the teeth are engaged at all times, errors are averaged out, resulting in exceptional repeatability for precise docking and navigation tasks.

Coaxial Geometry

The input and output shafts are coaxial (aligned). This geometry simplifies chassis design, allowing motors to be mounted directly in line with wheels or joints.

How It Works: Strain Wave Logic

At the heart of a harmonic drive is an elliptical plug called the Wave Generator. When inserted into the Flexspline (a flexible, thin-walled steel cup with external teeth), it forces the Flexspline into an elliptical shape.

The Circular Spline is a rigid outer ring with internal teeth. Crucially, the Flexspline has two fewer teeth than the Circular Spline. As the Wave Generator rotates, it pushes the Flexspline teeth into mesh with the Circular Spline teeth along the major axis of the ellipse.

For every full rotation of the Wave Generator, the Flexspline rotates in the opposite direction by a distance of two teeth. This creates a massive reduction ratio in a incredibly compact space, converting high-speed motor input into low-speed, high-torque output.

- Input: High Speed (Wave Generator)

- Output: High Torque (Flexspline or Circular Spline)

- Efficiency: Contact across ~30% of teeth simultaneously

Real-World Applications

Steering Modules

In omnidirectional AGVs, harmonic drives are used in steering actuators to rotate wheel pods. The zero-backlash property allows the robot to calculate odometry precisely without mechanical drift.

Mobile Manipulators (AMRs)

For AGVs equipped with robotic arms (cobots), harmonic drives provide the joints with the necessary holding torque and smoothness to pick and place delicate items while the base is mobile.

Compact Wheel Hubs

Due to their flat, "pancake" profile, harmonic gears can be integrated directly inside the wheel hub of smaller warehouse robots, saving valuable chassis space for batteries and cargo.

Heavy-Lift Pallet Jacks

The lifting mechanism in autonomous forklifts utilizes the extreme torque multiplication of harmonic drives to raise heavy pallets vertically with a relatively small electric motor.

Frequently Asked Questions

What is the primary advantage of a Harmonic Drive over a Planetary Gearbox?

The primary advantage is "Zero Backlash." While planetary gears usually have a small amount of play (backlash) between teeth, the flexible nature of the Harmonic Drive ensures teeth are always pre-loaded and engaged. This results in superior positioning accuracy and repeatability.

Are Harmonic Drives suitable for high-speed applications?

Generally, no. They are designed for high-torque, low-speed output. While the input speed (Wave Generator) can be high (up to 6000-7000 RPM), the friction generated by the Flexspline deformation creates heat limits. They are ideal for precise positioning rather than continuous high-speed rotation.

How does the efficiency compare to other gear types?

Harmonic drives are generally less efficient than planetary gears, typically ranging between 80% to 90% efficiency depending on the ratio and speed. The efficiency drops significantly at very low temperatures or very low torque loads due to the energy required to flex the metal spline.

What is "Ratcheting" and when does it occur?

Ratcheting is a catastrophic failure mode where the torque load exceeds the holding capability of the drive, causing the Flexspline teeth to jump over the Circular Spline teeth. This usually happens during shock loads (like an AGV crashing) and permanently damages the gear teeth.

What maintenance is required for Harmonic Drives in AGVs?

The primary maintenance is lubrication. Special harmonic grease (often lithium-based with extreme pressure additives) is required. In sealed "component set" units, they may be maintenance-free for life, but open units require periodic re-greasing to prevent fretting wear on the Flexspline.

Why are they more expensive than standard gears?

The manufacturing process is extremely demanding. The Flexspline requires high-grade steel capable of withstanding millions of bending cycles without fatigue, and the tooth profiles require micron-level precision cutting. This material science and precision machining drive up the cost.

What is the typical lifespan of a Harmonic Drive?

Lifespan is usually rated in "L10 life" hours at a specific average speed and torque. A typical unit might last 7,000 to 10,000 hours of operation. The limiting factor is usually the fatigue life of the flexible bearing in the Wave Generator or the Flexspline cup itself.

Can Harmonic Drives handle high radial and axial loads?

Standard component sets are not designed for high external loads on the output shaft. However, "housed" units often include integrated cross-roller bearings on the output, which provide exceptional stiffness and capacity to handle heavy radial, axial, and moment loads typical in robotic arms.

Are there different gear ratios available?

Yes, standard ratios are typically 30, 50, 80, 100, 120, and 160:1. Because the ratio is determined by the number of teeth (which is an integer), the ratios are fixed steps. You cannot easily get a custom ratio like 42.5:1 without redesigning the entire gear set.

How does a Harmonic Drive impact AGV battery life?

While slightly less efficient than planetary gears, the high reduction ratio allows for smaller, more efficient motors to be used. This often results in a net positive for battery life by reducing the total weight of the powertrain, provided the drive is not utilized in a continuous high-friction speed zone.