H-Bridge Motor Drivers

The fundamental electronic circuit that grants AGVs precise bidirectional control. Bridging the gap between low-voltage logic and high-power motion, H-Bridges are essential for the navigation, speed modulation, and braking of modern mobile robots.

Core Concepts

Bidirectional Control

The primary function of an H-Bridge is reversing polarity across the motor, allowing AGVs to drive forward and backward instantly without mechanical relays.

PWM Modulation

By pulsing the transistors on and off rapidly (Pulse Width Modulation), the driver controls the effective voltage, enabling smooth acceleration and precise speed limits.

MOSFET Efficiency

Modern drivers use MOSFETs with low internal resistance (Rds-on). This minimizes voltage drop and heat generation, which is critical for extending battery life in mobile robots.

Dynamic Braking

By shorting the motor terminals (turning on both bottom switches), the H-Bridge utilizes Back-EMF to create rapid, controlled stopping power essential for safety.

Shoot-Through Protection

Advanced drivers include "dead time" logic to prevent the top and bottom switches on the same side from opening simultaneously, preventing catastrophic short circuits.

Logic Interface

These drivers isolate high motor voltages (24V/48V) from sensitive microcontroller logic (3.3V/5V), protecting the robot's "brain" from electrical noise and spikes.

How It Works

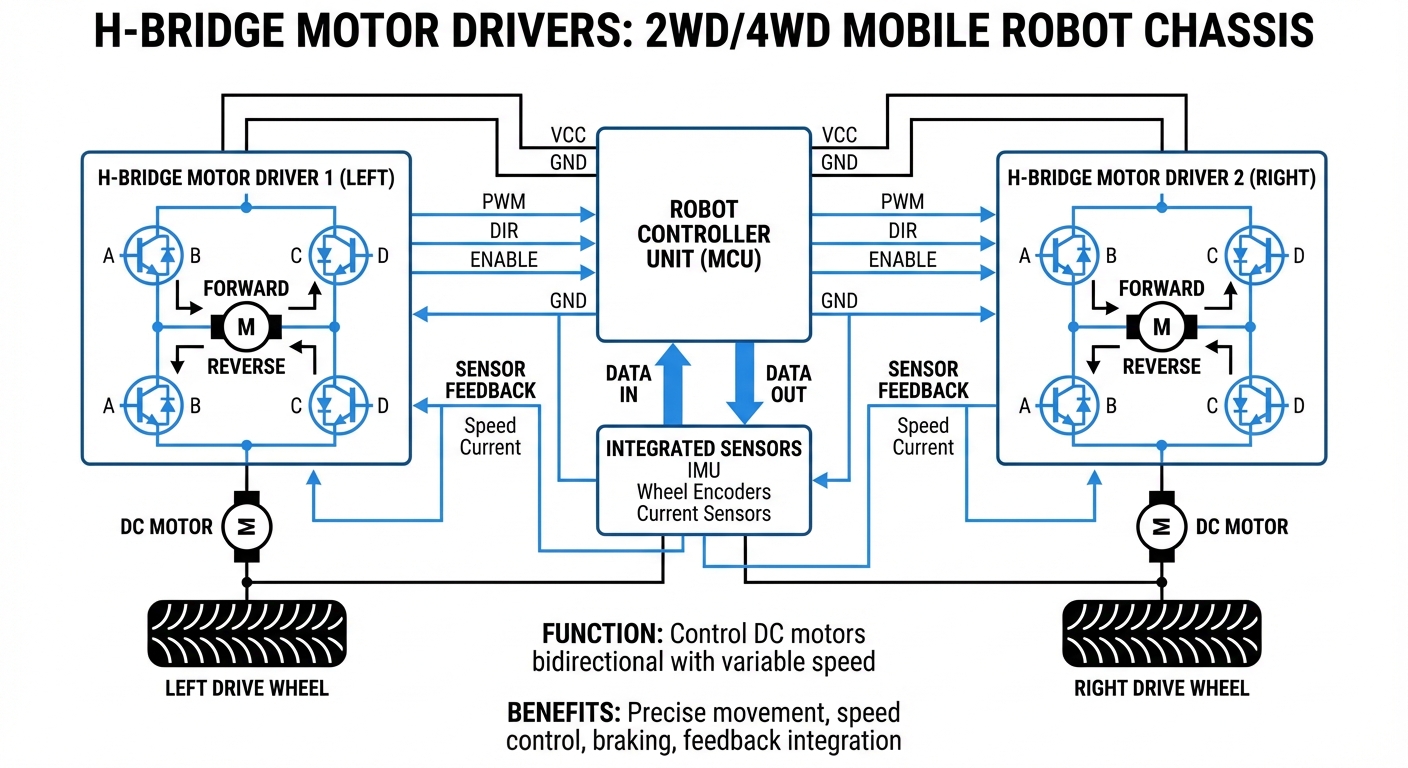

The name "H-Bridge" is derived from the graphical representation of the circuit, which resembles the letter 'H'. It typically consists of four switching elements—usually MOSFETs in modern robotics—arranged with the motor in the center.

Forward Motion: Switches Q1 (Top Left) and Q4 (Bottom Right) close. Current flows from the positive supply, through the motor, to ground.

Reverse Motion: Switches Q3 (Top Right) and Q2 (Bottom Left) close. Current enters the motor from the opposite side, reversing the magnetic field and the rotation direction.

This simple yet effective topology allows complex path planning algorithms to translate digital signals into physical movement.

Real-World Applications

Automated Warehouses

High-current H-Bridges drive the heavy-duty DC motors in forklifts and pallet jacks, allowing for millimeter-precise docking and heavy load lifting.

Differential Drive Robots

By using two separate H-Bridge channels (one for the left wheel, one for the right), robots can turn in place (zero-radius turn) by spinning wheels in opposite directions.

Medical Transport Carts

Hospital robots require silent operation. High-frequency PWM H-Bridges (above 20kHz) eliminate audible motor whine while navigating corridors.

Mecanum Wheel Platforms

Omnidirectional robots use four independent H-Bridges to drive four wheels separately, allowing lateral movement without rotating the chassis.

Frequently Asked Questions

What is the difference between an L298N and a modern MOSFET driver?

The L298N uses older BJT technology which creates a significant voltage drop (up to 2V) and generates excess heat. Modern drivers use MOSFETs with incredibly low resistance, delivering almost all battery power to the motor and running much cooler, which is vital for efficient AGVs.

Why do I need dead-time insertion?

Dead-time creates a microsecond delay when switching directions. Without it, the "top" and "bottom" switches on one side might be open simultaneously for a fraction of a second, causing a short circuit (shoot-through) that can destroy the driver and battery.

How does PWM frequency affect motor performance?

Low frequency PWM can cause motor vibration and audible noise. High frequency (ultrasonic, >20kHz) is silent but increases switching losses in the driver. For most AGVs, a balance between 10kHz and 20kHz is optimal for efficiency and quiet operation.

What is Regenerative Braking in the context of H-Bridges?

Regenerative braking allows the motor to act as a generator when slowing down, feeding energy back through the H-Bridge into the battery. This extends the runtime of mobile robots, especially in environments with frequent stops and starts.

Can I use a single H-Bridge for two motors?

Technically yes, if you wire them in parallel, but they will always move at the same speed and direction. For steering (differential drive), you strictly need one independent H-Bridge channel per motor wheel.

How do I calculate the current rating I need?

Don't look at the continuous current rating of the motor alone. You must size the driver for the "Stall Current"—the amount of power drawn when the motor is stopped forcibly. A good rule of thumb is to choose a driver that can handle 2x the motor's continuous current.

What protection features are standard in industrial drivers?

Industrial-grade drivers usually include Over-Current Protection (OCP), Thermal Shutdown (TSD), Under-Voltage Lockout (UVLO), and protection against ESD (Electrostatic Discharge). These safeguard the expensive robotics hardware.

Why do I need a heatsink on my H-Bridge?

Even with efficient MOSFETs, high currents (e.g., 20A+) generate heat due to resistance. If the junction temperature exceeds 150°C, the component fails. Heatsinks dissipate this thermal energy to keep the driver within a safe operating range.

What is galvanic isolation and do I need it?

Galvanic isolation physically separates the high-power motor circuit from the low-power logic circuit (often using optocouplers). For expensive industrial AGVs, this is highly recommended to prevent motor noise or failure from destroying the main computer.

Can H-Bridges handle Stepper Motors?

Yes. A bipolar stepper motor requires two H-Bridges (one for each coil). By energizing the H-Bridges in a specific sequence, the motor steps precisely. Many dedicated stepper drivers simply contain two H-Bridges in one chip.