Fuel Cells in Robotics

Revolutionize your AGV fleet efficiency with hydrogen fuel cell technology. Eliminate battery charging downtime, maintain constant voltage under heavy loads, and achieve true 24/7 operation for high-throughput logistics environments.

Core Concepts

Rapid Refueling

Unlike batteries that require hours to charge, hydrogen fuel tanks can be refilled in 2-3 minutes, maximizing robot utilization rates.

Constant Voltage

Fuel cells provide consistent power output until the tank is empty, avoiding the "voltage droop" seen in batteries as they deplete.

Zero Emissions

The only byproduct of the electrochemical reaction is pure water vapor, making them safe for indoor warehouses and food-grade facilities.

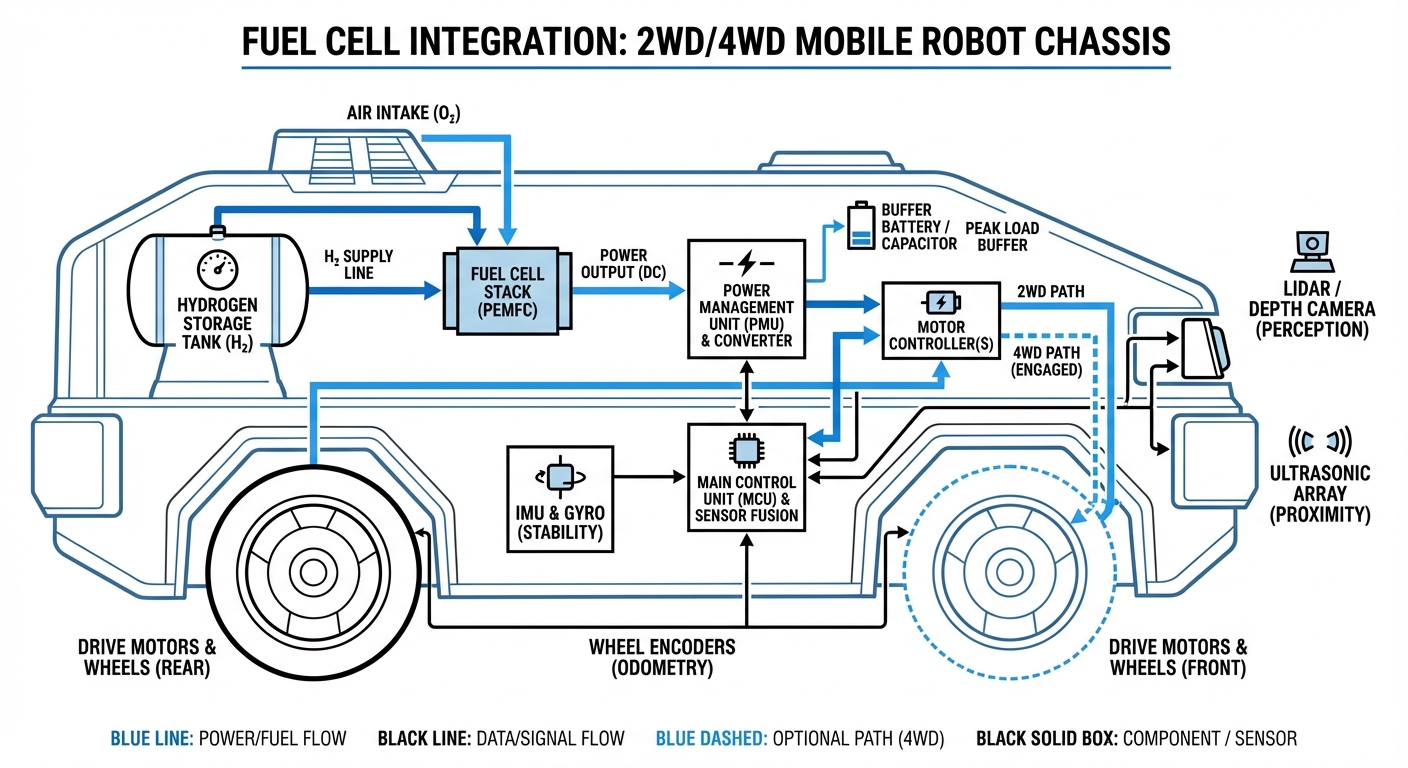

Hybrid Architecture

Most robotic systems use a fuel cell to maintain charge on a small buffer battery (supercapacitor), handling peak power demands efficiently.

Energy Density

Hydrogen offers superior energy-to-weight ratios compared to lead-acid or Li-Ion batteries, ideal for heavy-payload AGVs.

Cold Storage

Fuel cells operate effectively in freezing temperatures (-30°C) where battery chemistry typically degrades or loses capacity rapidly.

How It Works: Proton Exchange Membrane

At the heart of modern robotic fuel cells is the Proton Exchange Membrane (PEM). Hydrogen gas is fed into the anode side of the fuel cell stack, while oxygen from the ambient air enters the cathode side. A catalyst splits the hydrogen atoms into protons and electrons.

The membrane allows only the protons to pass through to the cathode. The electrons are forced to travel through an external circuit, generating the electrical current that powers the AGV's motors and sensors.

At the cathode, the electrons and protons recombine with oxygen to form water. This process generates electricity continuously as long as fuel is supplied, eliminating the need for long recharge cycles associated with battery-only systems.

Real-World Applications

High-Throughput Distribution Centers

In facilities running 24/7/365, fuel cells eliminate the need for battery swapping rooms or idle charging time. Robots spend 99% of their time moving goods, drastically improving ROI per unit.

Cold Chain Logistics

Refrigerated warehouses are notoriously difficult for batteries. Fuel cells maintain performance in sub-zero environments, powering pallet jacks and forklifts without the rapid discharge seen in lead-acid alternatives.

Heavy Manufacturing

For AGVs towing heavy automotive chassis or aerospace components, the high energy density of hydrogen ensures the robot can complete long shifts under heavy load without stopping to recharge.

Large Campus Delivery

Outdoor autonomous delivery robots traversing large university or corporate campuses benefit from the extended range of fuel cells, reducing "range anxiety" and the need for frequent docking stations.

Frequently Asked Questions

How does the cost of fuel cells compare to Li-Ion batteries?

While the initial hardware cost for fuel cells is generally higher than Li-Ion batteries, the Total Cost of Ownership (TCO) is often lower for fleets larger than 20 units. This savings comes from the elimination of battery swapping infrastructure, reclaimed warehouse space (no charging rooms), and significantly higher asset utilization.

Is hydrogen fuel safe for indoor use?

Yes, modern hydrogen systems are designed with rigorous safety standards. Hydrogen is lighter than air and dissipates rapidly upward if a leak occurs, unlike propane which pools. Robotics systems include leak detection sensors and automatic shut-off valves to ensure safety in indoor environments.

How is the hydrogen supplied to the facility?

Hydrogen can be delivered via truck (liquid or compressed gas) to an outdoor storage tank, similar to propane or diesel. Alternatively, some large facilities use on-site electrolyzers to generate hydrogen from water and electricity, creating a self-sufficient energy loop.

What is the typical lifespan of a fuel cell stack?

Modern PEM fuel cell stacks for material handling typically last between 10,000 to 20,000 operating hours before requiring refurbishment or replacement. This creates a predictable maintenance cycle that often aligns with the lifespan of the AGV chassis itself.

Can I retrofit my existing battery-powered AGVs?

Yes, many fuel cell power packs are designed as "drop-in" replacements for standard lead-acid battery compartments. They fit the same physical footprint and voltage requirements, allowing for a phased migration of your existing fleet without buying new robots.

Do fuel cells work with regenerative braking?

Fuel cells themselves do not absorb energy; however, fuel cell power units are hybrid systems containing a small Li-Ion battery or supercapacitor. This buffer captures energy from regenerative braking and provides peak power for lifting or acceleration.

What maintenance is required for the power unit?

Maintenance is minimal compared to lead-acid batteries (no watering required). It typically involves checking and replacing the air filter to protect the stack from dust and debris, and occasionally inspecting the cooling system, usually on a semi-annual basis.

How does refueling work for an AGV?

Refueling is performed by an operator at a dispenser, similar to a gas pump. The nozzle locks onto the robot's receptacle, and the fill takes 1-3 minutes. Fully automated robotic refueling stations are also emerging, allowing completely unmanned operations.

What happens if the hydrogen runs out mid-task?

The onboard Battery Management System (BMS) monitors fuel levels constantly. Most systems are programmed to return to base or alert an operator when fuel drops below a specific threshold (e.g., 10%), preventing the robot from being stranded.

Does altitude affect fuel cell performance?

Fuel cells require oxygen from the air to operate. At very high altitudes, the air is thinner, which can slightly reduce peak power output. However, for most warehouse and industrial applications, the compressors compensate for this automatically.

What are the environmental benefits?

At the point of use, fuel cells produce zero carbon emissions. If the hydrogen is sourced from renewable energy (Green Hydrogen), the entire energy cycle is carbon-neutral, significantly reducing the facility's overall carbon footprint compared to grid-charged batteries.

Are there voltage drops as the tank empties?

No. Unlike batteries, which experience voltage sag as they discharge (slowing down the robot), a fuel cell provides constant, full voltage output until the very last bit of hydrogen is consumed, ensuring consistent robot speed and lift capacity.

Ready to implement Fuel Cells in your fleet?

Transitioning to hydrogen power can increase your fleet productivity by up to 15%. Contact our engineering team for a site assessment.

Explore Our Robots