Forward Kinematics

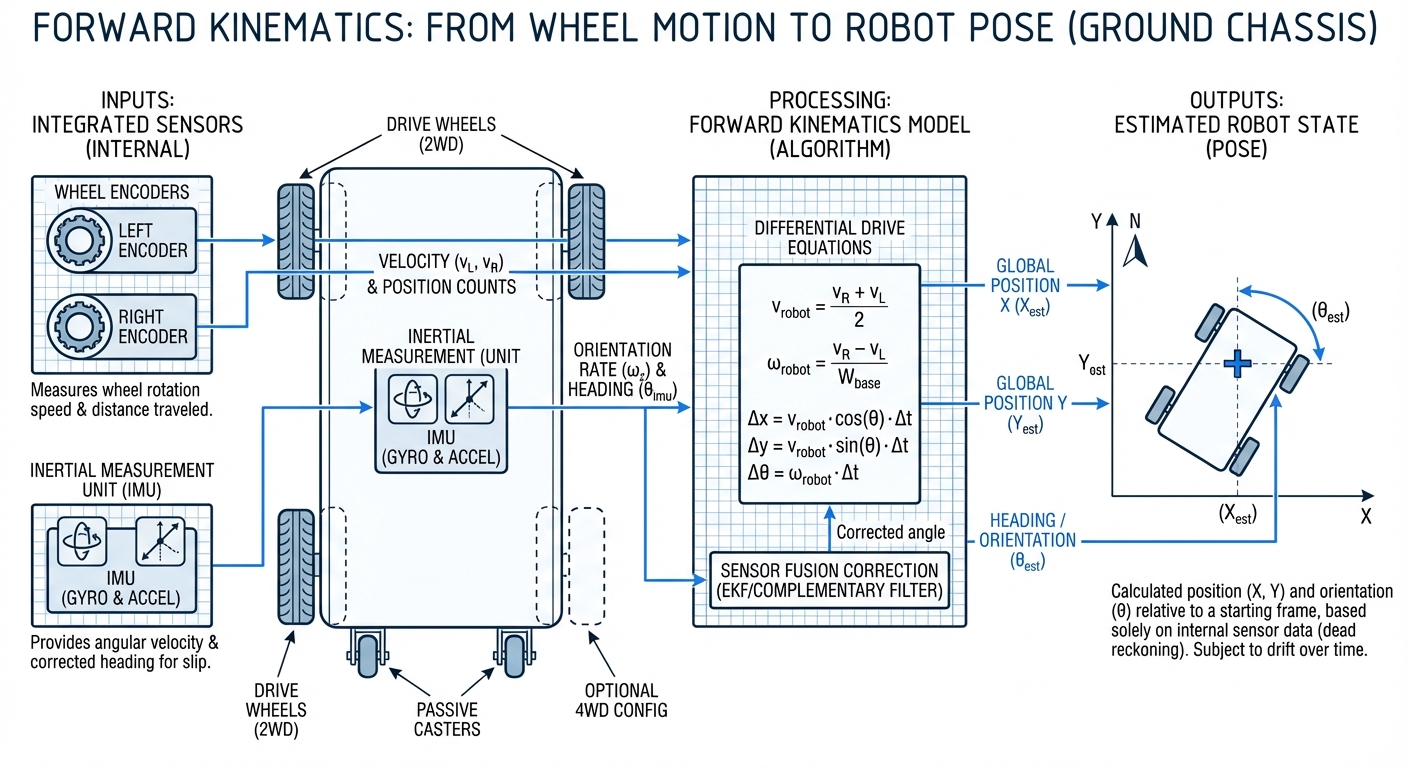

Forward Kinematics is the mathematical engine that translates internal joint parameters—like wheel velocity and steering angles—into precise position and orientation. It is the fundamental algorithm enabling Automated Guided Vehicles (AGVs) to calculate their pose within a global coordinate system solely based on internal sensors.

Core Concepts

The Robot Frame

Understanding the robot's local coordinate system (X, Y, Z). All sensor data originates here before being translated to the world map.

Transformation Matrices

The mathematical matrices used to compute the position and orientation of the end-effector or chassis relative to the base frame.

Wheel Odometry

Using rotary encoders to measure wheel rotation. These raw counts are the primary inputs for kinematic equations in mobile robots.

Pose Estimation

Calculating the specific state of the robot, usually defined as (x, y, θ), representing 2D position and heading orientation.

Differential Drive

The logic for 2-wheel drive robots where steering is achieved by varying the speeds of left and right wheels independently.

Dead Reckoning

The process of calculating current position by using a previously determined position and incorporating estimates of speed over time.

How It Works

In the context of mobile robotics, Forward Kinematics acts as the bridge between the hardware and the mapping software. It takes known values—specifically the geometry of the robot (wheel radius, wheelbase) and the rotational velocity of the wheels—to compute the unknown robot velocity in the global frame.

For a standard differential drive AGV, the algorithm integrates the velocity over small time steps. By calculating the linear velocity (v) and angular velocity (ω) from the left and right wheel speeds, the system updates the robot's global X, Y coordinates and Theta (heading) angle.

While powerful, Forward Kinematics relies heavily on the accuracy of wheel-ground interaction. Without external correction from LiDAR or cameras, small errors (slippage) accumulate over time, leading to "drift"—a challenge solved by sensor fusion.

Real-World Applications

Warehouse Logistics

AGVs use forward kinematics for short-range navigation between QR code checkpoints. It allows the robot to maintain a smooth path while transporting pallets between shelving units without constant reliance on GPS, which fails indoors.

Precision Manufacturing

In assembly lines, mobile manipulators rely on kinematic calculations to dock precisely at workstations. The algorithm ensures the chassis is positioned exactly right so the robotic arm can reach the workpiece.

Hospital Delivery Bots

For autonomous delivery of linens and medicine, kinematics allows robots to navigate long corridors and execute precise turns around obstacles, ensuring safety in high-traffic human environments.

Agricultural Robotics

Field robots rely on kinematic models to traverse uneven terrain. Advanced models account for wheel slip on mud to estimate position when GPS signals are blocked by tree canopies or structures.

Frequently Asked Questions

What is the difference between Forward and Inverse Kinematics?

Forward Kinematics calculates the position and orientation of the robot based on joint/wheel inputs. Conversely, Inverse Kinematics starts with a desired target position and calculates the necessary wheel speeds or joint angles required to reach that destination.

Why does Dead Reckoning drift over time?

Dead reckoning relies purely on internal sensors (odometry). Small errors, such as wheel slippage, uneven floors, or tire compression, create minute discrepancies. Since forward kinematics integrates position over time, these errors accumulate, causing the estimated position to drift away from the actual position.

How does wheel configuration affect the kinematic model?

The math changes significantly based on the drivetrain. A differential drive (2 wheels) uses a simple non-holonomic constraint model. However, Mecanum or Omni-wheel robots require complex vector summation to account for movement in X, Y, and Theta simultaneously (holonomic motion).

Can Forward Kinematics work without encoders?

Generally, no. Encoders provide the raw feedback of how much the wheels have turned. Without this data, the robot has no proprioception. However, visual odometry (cameras) or IMUs can act as substitutes in specific advanced implementations, though they measure motion differently.

What is the role of the Jacobian matrix?

The Jacobian matrix relates the joint velocities (wheel speeds) to the robot's linear and angular velocities in the global frame. It is essential for analyzing singularities and mapping the relationship between internal motion and external movement.

How do we correct kinematic errors in real-time?

We use Sensor Fusion, typically utilizing an Extended Kalman Filter (EKF). The EKF takes the forward kinematics estimation and fuses it with absolute position data from LiDAR, Cameras, or GPS to "snap" the robot back to its true location.

Does tire wear affect forward kinematics?

Yes. The kinematic equations rely on a constant wheel radius. As tires wear down, the radius decreases, meaning the robot travels less distance per rotation than calculated. This requires periodic recalibration of the wheel radius parameter in the software.

What is the impact of integration methods (Euler vs. Runge-Kutta)?

Basic Euler integration assumes velocity is constant between time steps, which is computationally cheap but less accurate. Runge-Kutta methods (like RK4) provide higher accuracy by sampling velocity at multiple points within the time step, reducing integration errors in highly dynamic maneuvers.

How is the Instantaneous Center of Rotation (ICR) used?

For any non-holonomic robot turning, there is a point around which the robot is momentarily rotating. Identifying the ICR helps in deriving the kinematic constraints and ensuring that the wheel velocities are consistent with a rigid body motion, preventing wheel drag.

Is 3D Kinematics necessary for warehouse AGVs?

Typically, no. Most warehouse floors are flat, so a 2D (X, Y, Theta) model is sufficient. 3D kinematics (X, Y, Z, Roll, Pitch, Yaw) becomes necessary for outdoor robots or drones where terrain elevation changes significantly.