EtherCAT

The central nervous system of modern autonomous mobile robots. EtherCAT delivers the real-time, sub-millisecond synchronization and deterministic control required for precision navigation and safety in complex industrial environments.

Core Concepts

Processing on the Fly

Unlike standard Ethernet, EtherCAT frames are processed by slave devices as they pass through, eliminating the need to receive, decode, and copy process data at every node.

Distributed Clocks

Achieves precise synchronization (< 1 µs jitter) across all servo drives, essential for omnidirectional AGV movement and multi-axis manipulator arms.

Flexible Topology

Supports Line, Tree, Star, or Daisy-chain topologies without performance loss. Perfect for routing cables through the tight chassis constraints of mobile robots.

Safety over EtherCAT (FSoE)

Transmits safety-critical data on the same cable as standard control data. Enables integrated E-Stops and safety scanners without separate wiring harnesses.

Max Bandwidth Utility

Utilizes the full bandwidth of 100 Mbit/s (or greater) Ethernet in full-duplex mode. Efficient packing of data frames maximizes throughput for sensor-heavy robots.

Hardware Independence

The Master requires only a standard Ethernet port, reducing the cost of the onboard computer. Slaves use specialized but affordable ASIC chips to handle high-speed data.

How It Works

In a standard Ethernet network, data packets are sent to specific devices, decoded, processed, and then a response is generated. This creates latency and jitter that is unacceptable for high-speed robotics.

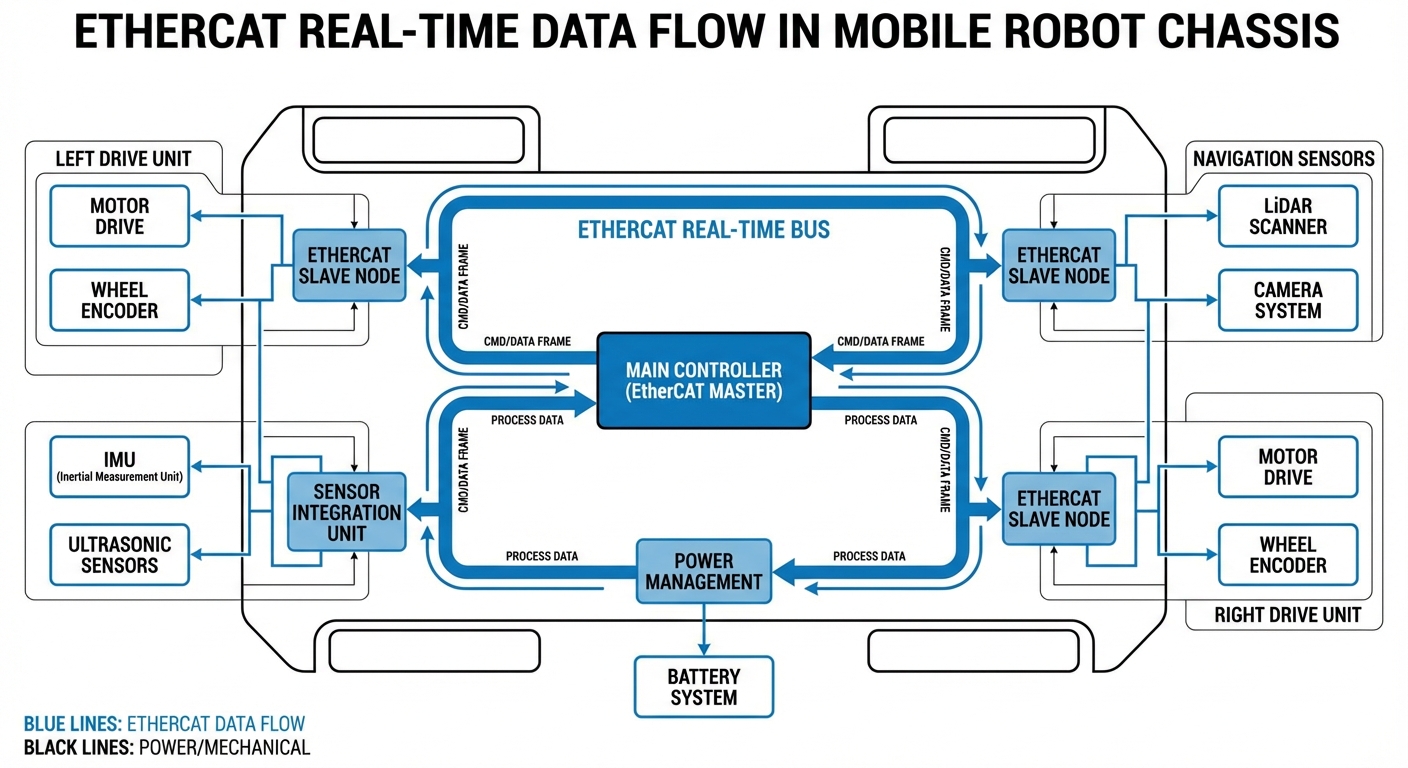

EtherCAT revolutionizes this by using a "telegram" train method. A single Ethernet frame is sent by the Master (the robot's main computer). This frame passes through every node (motor driver, I/O slice, sensor) in the network sequentially.

As the frame passes through, each device reads the data addressed to it and inserts its own output data while the frame is moving. This process is hardware-controlled, resulting in virtually no processing delay, allowing cycle times as fast as 100 µs for ultra-responsive AGV motion control.

Real-World Applications

Synchronized Mecanum Drive

AGVs utilizing Mecanum or Omni-wheels require four distinct motors to operate in perfect unison to achieve vector movement. EtherCAT Distributed Clocks ensure that torque commands reach all four wheels at the exact same microsecond, preventing drift and ensuring smooth diagonal movement.

LiDAR & Sensor Fusion

Modern AMRs process massive amounts of data from safety scanners and LiDARs. EtherCAT's high bandwidth allows for the rapid transmission of raw sensor data to the main controller, enabling real-time obstacle avoidance and dynamic path replanning.

Mobile Manipulation

For AGVs equipped with robotic arms (cobots), the mobile base and the arm must coordinate their movements to pick up objects while moving. EtherCAT unifies the base and arm controllers into a single network, simplifying the complex kinematics required for mobile manipulation.

Integrated Safety Logic

Using Safety over EtherCAT (FSoE), safety zones can be dynamically adjusted based on the robot's speed and load. If a human enters a zone, the safety command is propagated instantly via the Black Channel to the motor drives to trigger Safe Torque Off (STO) functions.

Frequently Asked Questions

What distinguishes EtherCAT from standard TCP/IP Ethernet?

Standard TCP/IP is non-deterministic, meaning packet arrival times can vary due to collisions and routing. EtherCAT uses the physical layer of Ethernet but employs a unique protocol where frames are processed on-the-fly by hardware, ensuring strictly deterministic real-time performance crucial for motion control.

Why is EtherCAT preferred for AGVs over CAN bus (CANopen)?

While CAN bus is robust, it lacks the bandwidth and speed required for modern, sensor-rich AGVs. EtherCAT offers significantly higher bandwidth (100 Mbps vs 1 Mbps), handles more nodes, and provides much tighter synchronization for complex drive systems like holonomic bases.

Do I need special switches or routers to build an EtherCAT network?

No. EtherCAT does not use switches or routers, which eliminates active infrastructure latency and cost. Devices are connected in a daisy-chain fashion (line topology), or branched using EtherCAT junctions, making the cabling architecture simple and cost-effective.

What is the maximum cable length between nodes?

EtherCAT adheres to the standard Ethernet 100BASE-TX physics, allowing for up to 100 meters (328 feet) between two nodes using CAT5e or better cables. For AGVs, this is more than sufficient, even for internal routing within large mobile platforms.

How does Safety over EtherCAT (FSoE) work?

FSoE uses a "Black Channel" approach, where safety data containers are transported within standard EtherCAT frames. The safety logic is handled by the end devices (safety PLC and drives) which verify data integrity, allowing safety-critical communication over non-safety cabling without dedicated wiring.

Does the Master controller need a specialized EtherCAT chip?

No. The Master (typically the AGV's onboard industrial PC) requires only a standard Ethernet port. The real-time capabilities are achieved via the Master software stack (e.g., TwinCAT, EtherLab) and the specialized hardware found in the Slave devices.

Can I connect standard Ethernet devices to an EtherCAT network?

Directly, no, as they don't understand the EtherCAT protocol. However, you can use "Ethernet over EtherCAT" (EoE) tunneling, which allows you to transport standard TCP/IP traffic across the EtherCAT network to a device connected to a specific switch port terminal.

What happens if a cable breaks or a node fails?

EtherCAT supports cable redundancy. By connecting the last node back to a second port on the Master (creating a ring), the system can tolerate a single cable break. The Master detects the break and instantly reroutes traffic, keeping the AGV operational for maintenance.

How does EtherCAT integrate with ROS/ROS2?

There are several open-source drivers (like the SOEM library) and ROS2 packages available that act as EtherCAT Masters. These packages expose the EtherCAT bus data as ROS topics, allowing high-level navigation planners to control low-level hardware transparently.

What is the typical cycle time achievable for an AGV?

For a typical AGV with 4-8 axes and several I/O modules, cycle times of 1ms (1000 Hz) are standard and easily achievable. Highly optimized systems can reach 250µs or even 100µs, though 1ms is usually sufficient for mobile robot kinematics.

Is hot-swapping of modules supported?

Yes, EtherCAT supports Hot Connect groups. This feature allows pre-configured sections of the network (like a specific tool attachment on a robot) to be connected or disconnected during runtime without disrupting the rest of the bus communication.

How does Distributed Clock (DC) synchronization work?

The DC mechanism measures the propagation delay between all nodes. It effectively aligns the internal clocks of every slave device to the reference clock. This allows all drives to apply torque at the exact same moment, regardless of their position in the daisy chain.