End Effectors and Grippers

End effectors act as the "hands" of autonomous mobile robots, transforming simple transport platforms into intelligent mobile manipulators. They define how a robot interacts with its environment, enabling precise picking, placing, and handling of materials across logistics and manufacturing workflows.

Core Concepts

Mechanical Grippers

The most common end-of-arm tooling, utilizing physical jaws or fingers to grasp objects. These can be driven electrically or pneumatically to provide high-force clamping for rigid items.

Vacuum Cups

Ideal for packaging and logistics, using suction to lift boxes, glass, or plastic. They require an integrated pump or venturi system within the mobile robot chassis.

Magnetic Grippers

Utilized specifically for handling ferrous materials. Electromagnets allow for rapid pick-and-place operations of metal sheets or components without complex mechanical fingers.

Soft Robotics

Made from compliant materials like silicone, these grippers adapt to the shape of the object. They are essential for handling fragile items, food products, or irregular geometries safely.

Automatic Tool Changers

Devices that allow an AGV to swap its end effector autonomously. This maximizes fleet utilization by allowing one robot to perform palletizing, bin picking, and assembly tasks.

Force/Torque Sensors

Integrated feedback mechanisms that give the robot a sense of "touch." This is critical for mobile manipulation where precise alignment with the target object cannot always be guaranteed.

How It Works

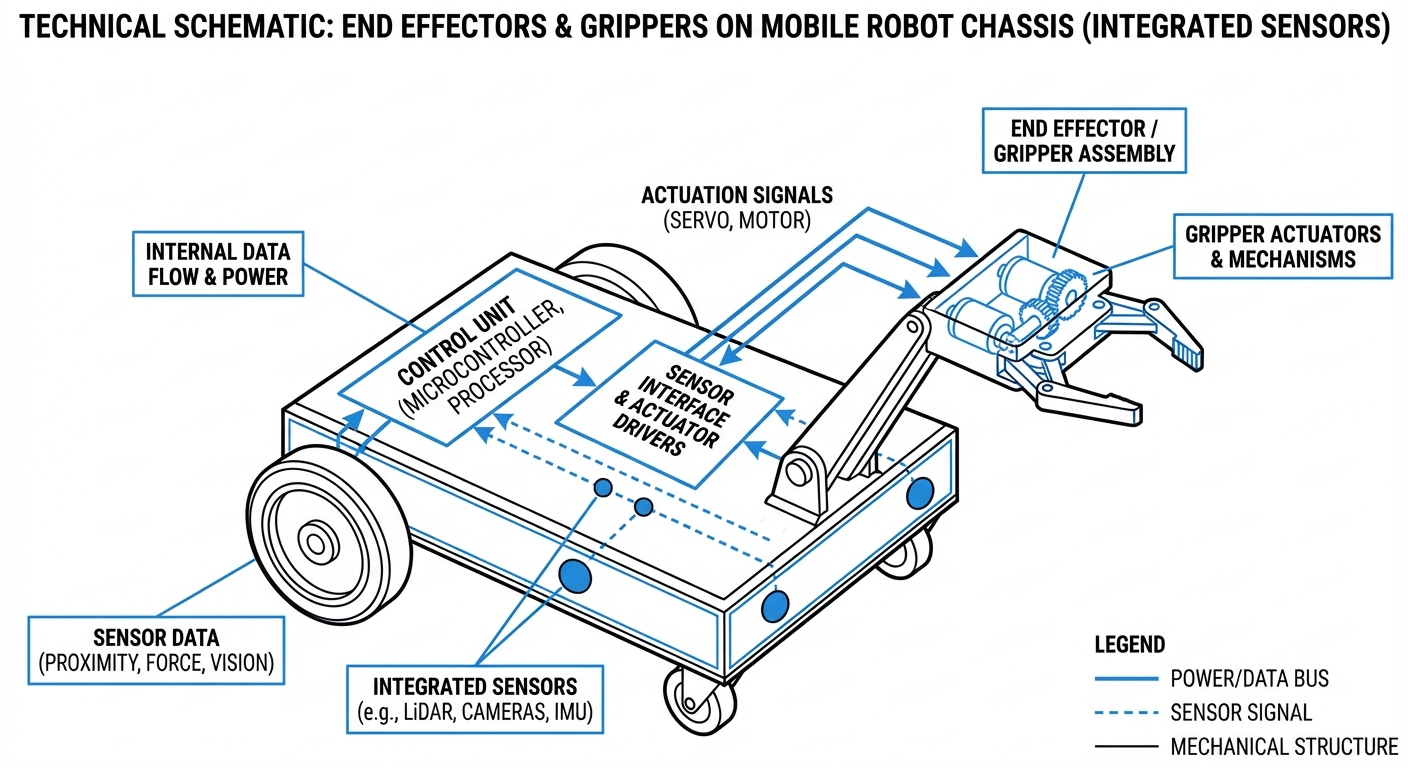

The end effector is the bridge between the robot's computational brain and the physical world. In mobile robotics, the end effector is mounted on an arm or a linear actuator attached to the AGV chassis. The integration involves three main components: mechanical coupling, power transmission, and signal communication.

For power, mobile robots typically favor electrical grippers over pneumatic ones to preserve battery life and eliminate the need for bulky air compressors. However, self-contained vacuum generation units are common for logistics applications.

Communication is handled via protocols like IO-Link, PROFINET, or EtherCAT. This allows the AGV's central controller to send "open/close" commands while receiving real-time data from the gripper regarding grip success, object width, and applied force.

Real-World Applications

Mobile Bin Picking

Autonomous Mobile Robots (AMRs) equipped with vision-guided parallel grippers navigate warehouse aisles to pick individual items (eaches) from bins and consolidate them into orders.

Machine Tending

In manufacturing, AGVs with dual-gripper setups load raw materials into CNC machines and unload finished parts in a single cycle, significantly reducing machine idle time.

Laboratory Automation

High-precision electric grippers on mobile bases handle microplates and vials in biotech labs. These grippers feature adjustable force control to prevent crushing delicate samples.

End-of-Line Palletizing

Heavy-duty vacuum or clamping effectors mounted on high-reach AGVs stack boxes onto pallets. These systems automatically adjust their grip based on box weight and dimensions.

Frequently Asked Questions

What is the difference between an end effector and a gripper?

An end effector (End-of-Arm Tooling or EOAT) is a general term for any device attached to the end of a robot arm to interact with the environment. A gripper is a specific type of end effector designed to grasp and hold objects. Other end effectors include welding torches, screw drivers, or dispensing nozzles.

Are electric or pneumatic grippers better for AGVs?

Electric grippers are generally preferred for AGVs and AMRs. They are more energy-efficient, offer precise control over position and force, and do not require the robot to carry a heavy air compressor or navigate to air drops. Pneumatic grippers are typically reserved for stationary applications or very high power-to-weight ratio requirements.

How do I calculate the required payload capacity for a gripper?

You must calculate the total payload by adding the weight of the object being lifted to the weight of the gripper itself. Furthermore, you must account for acceleration forces during the AGV's movement (inertia) and the friction coefficient between the gripper fingers and the object. A safety factor of 2x or 3x is standard.

Can a single gripper handle multiple types of products (high-mix)?

Yes, adaptive grippers (often 2 or 3-finger designs) with long strokes can handle various part sizes. Alternatively, automatic tool changers allow the AGV to swap grippers entirely for different tasks. Soft robotic grippers are also excellent for high-mix scenarios involving irregular shapes.

What safety considerations exist for grippers on mobile robots?

For collaborative applications (ISO/TS 15066), grippers must lack sharp edges and possess limited gripping force to prevent pinching injuries. Many modern grippers detect collisions and stop immediately. If the power fails, the gripper should have a fail-safe mechanism (like a mechanical spring) to prevent dropping the load.

How does the gripper communicate with the AGV navigation stack?

Communication usually occurs over industrial protocols like IO-Link, Modbus TCP, or ROS (Robot Operating System) drivers. The navigation software tells the robot where to go, and once positioned, triggers the manipulation sequence via the gripper controller.

What is the maintenance requirement for mechanical grippers?

Maintenance typically involves periodic lubrication of moving parts, checking for wear on the fingertips (pads), and verifying cable connections. Electric grippers generally require less maintenance than pneumatic ones, which may suffer from seal degradation or air leaks over time.

Can vacuum grippers work on porous surfaces like cardboard?

Yes, but it requires a high-flow vacuum generator to compensate for air leakage through the material. Specialized suction cups with softer lips or foam sealing rings are also used to create a better seal on textured or porous surfaces.

How much power do electric grippers consume from the AGV battery?

It varies, but generally, consumption is low. Energy is mostly consumed during the actuation (opening/closing). Many electric grippers have self-locking mechanisms that require zero power to maintain a grip once the object is held, optimizing battery life for long transport routes.

What is 3D vision integration with grippers?

3D vision integration involves mounting a camera on or near the gripper. The camera identifies the object's position and orientation (pose estimation) in 3D space, adjusting the gripper's approach vector to pick the item successfully, even if the AGV isn't perfectly aligned.

Are custom 3D-printed fingers durable enough for industrial use?

Increasingly, yes. Using engineering-grade materials like carbon-fiber-reinforced nylon, custom fingers can be printed to match the exact contour of a part. This improves grip stability and allows for rapid prototyping of tooling without expensive machining.