Differential Drive Chassis

The foundational architecture for modern Autonomous Guided Vehicles (AGVs). By independently controlling two drive wheels, this chassis delivers exceptional maneuverability, zero-radius turning, and robust simplicity for indoor logistics and service robotics.

Core Concepts

Zero Turn Radius

Unlike car-like steering, differential drives can rotate in place. By spinning wheels in opposite directions, the robot pivots around its center axis, essential for tight warehouse aisles.

Kinematics & ICR

Movement is defined by the Instantaneous Center of Rotation (ICR). The robot's trajectory is determined entirely by the velocity difference between the left and right wheels.

Stability & Casters

A two-wheel system is inherently unstable. Passive caster wheels (swivel wheels) are added to the front or rear to maintain balance without adding steering complexity.

Wheel Odometry

Position tracking relies heavily on rotary encoders. By counting wheel revolutions, the robot calculates its relative position and heading, though this is prone to drift over time.

Power Efficiency

Compared to Mecanum or Holonomic drives, differential drive is highly energy-efficient. Traction is direct, with no vector force losses, maximizing battery life for long shifts.

Simplistic Control

The control logic is straightforward PID. There are no complex linkages or steering servos to maintain, resulting in lower hardware costs and higher reliability.

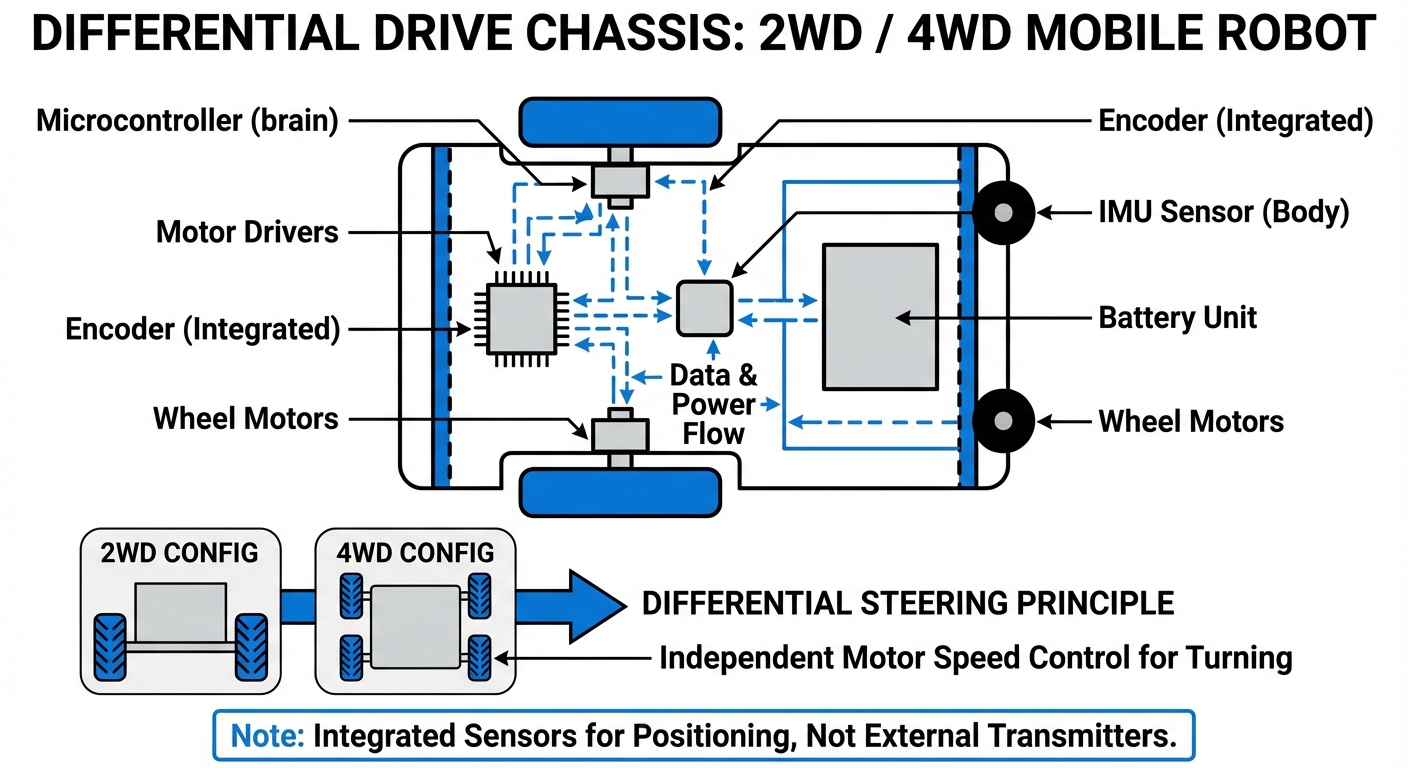

How It Works: The Mechanics

The differential drive system operates on a principle similar to a tank, but typically uses wheels instead of tracks. It consists of two prime movers (motors) mounted on a common axis. The robot's motion is dictated purely by modulating the speed of these two motors.

Straight Motion: Both wheels spin at the exact same velocity.

Turning: One wheel spins faster than the other. The robot turns toward the slower wheel.

Spinning: Wheels spin at equal speeds but in opposite directions.

This mechanical simplicity reduces the points of failure significantly. There is no steering rack, no tie rods, and no complex suspension geometry required for basic indoor AGV applications.

Real-World Applications

Warehouse Fulfillment

Used in Kiva-style shelf-lifting robots. The ability to spin 360° under a pod rack allows for high-density storage and rapid retrieval in fulfillment centers.

Hospital Material Transport

AMRs delivering linens, meals, and medication rely on differential drive to navigate narrow hospital corridors and enter elevators without requiring wide turning circles.

Commercial Cleaning

Autonomous floor scrubbers utilize this chassis to follow precise cleaning paths, ensuring complete coverage near walls and obstacles via precise yaw control.

Manufacturing Line Delivery

Tugger AGVs using differential drive transport parts between assembly cells. Their simplicity ensures high uptime in demanding 24/7 production environments.

Frequently Asked Questions

What is the main advantage of a differential drive chassis over Ackerman steering?

The primary advantage is the turning radius. Ackerman steering (like a car) has a minimum turning radius restricted by the mechanical limits of the front wheels. Differential drive robots can rotate in place (zero-turn radius), making them far superior for navigating tight indoor spaces and dead-end aisles.

How does wheel slippage affect differential drive robots?

Wheel slippage is a significant issue for "dead reckoning" navigation. If a wheel spins without moving the robot (e.g., on a wet floor), the encoders count rotation, leading the robot to believe it has moved further or turned more than it actually has. This requires external sensors like LiDAR or IMUs to correct position.

Why are caster wheels necessary?

A two-wheel differential drive platform acts like a pendulum; it cannot balance on just two points. Caster wheels provide the third and fourth contact points for static stability. They are passive and swivel freely to follow the robot's movement driven by the main wheels.

Is differential drive better than Mecanum or Omni-wheel drives?

It depends on the application. Mecanum drives allow for lateral (sideways) movement, which differential drives cannot do. However, differential drives are cheaper, simpler, have higher load capacities, and are more energy-efficient because they don't fight vector forces in the wheel rollers.

What type of motors are best for this chassis?

Brushless DC (BLDC) motors with planetary gearboxes are the industry standard. They offer high torque at low speeds, precise control, long maintenance intervals, and closed-loop speed control when paired with high-resolution encoders.

How do you calculate the robot's heading?

Heading is calculated by integrating the difference in distance traveled by the left and right wheels over time, divided by the wheelbase (distance between wheels). However, this mathematical model degrades over long distances, requiring Gyroscope/IMU fusion for accuracy.

What is the typical payload capacity?

Differential drive is highly scalable. While small educational robots carry less than 1kg, industrial heavy-payload AGVs utilizing differential drive can move pallets weighing upwards of 1,000kg to 1,500kg, provided the motors and chassis structure are sized correctly.

Can this chassis handle outdoor terrain?

Generally, no. Differential drive robots with caster wheels are optimized for flat, smooth indoor surfaces. Outdoors, small caster wheels get stuck in cracks or gravel. For outdoor terrain, skid-steer (4-wheel drive) or tracked differential systems are preferred.

What is the "Wheelbase" and why does it matter?

The wheelbase is the distance between the contact points of the two drive wheels. A wider wheelbase provides better stability during turns but requires more space to rotate. A narrow wheelbase is more agile but can be "twitchy" at high speeds, making straight-line driving harder to control.

How do you handle motor synchronization?

Since no two motors are perfectly identical, sending the same voltage to both will result in a curve, not a straight line. PID (Proportional-Integral-Derivative) controllers monitor the encoders on each wheel continuously to adjust voltage thousands of times per second, ensuring both wheels match the target velocity.

What safety sensors are compatible with this drive?

Because the robot can turn in place, safety LiDAR scanners are typically mounted on diagonally opposite corners (or two scanners for 360° coverage) to detect obstacles. Bumper switches and emergency stop buttons are also standard integrations for industrial compliance.