Center of Gravity Optimization

Mastering vehicle stability is critical for next-generation AGVs. Discover how real-time Center of Gravity (CoG) analysis prevents tip-overs, enhances acceleration profiles, and ensures safety across dynamic warehouse environments.

Core Concepts

Static Stability

The foundational baseline where the robot's vertical projection of CoG falls within the support polygon defined by its wheel contact points.

Dynamic Load Shifts

Accounting for inertia when an AGV accelerates, brakes, or turns. The effective CoG shifts temporarily, requiring real-time motor torque adjustments.

Vertical Distribution

Managing the Z-axis height. Lowering the mass of heavy components (batteries, motors) drastically improves the stability margin during lifting operations.

Payload Variance

Adapting to unknown weights. An AGV carrying 50kg handles differently than one carrying 500kg; systems must estimate mass to optimize control loops.

Terrain Compensation

Adjusting CoG calculations for inclined surfaces or ramps. A 10-degree slope significantly alters the tipping point vector relative to gravity.

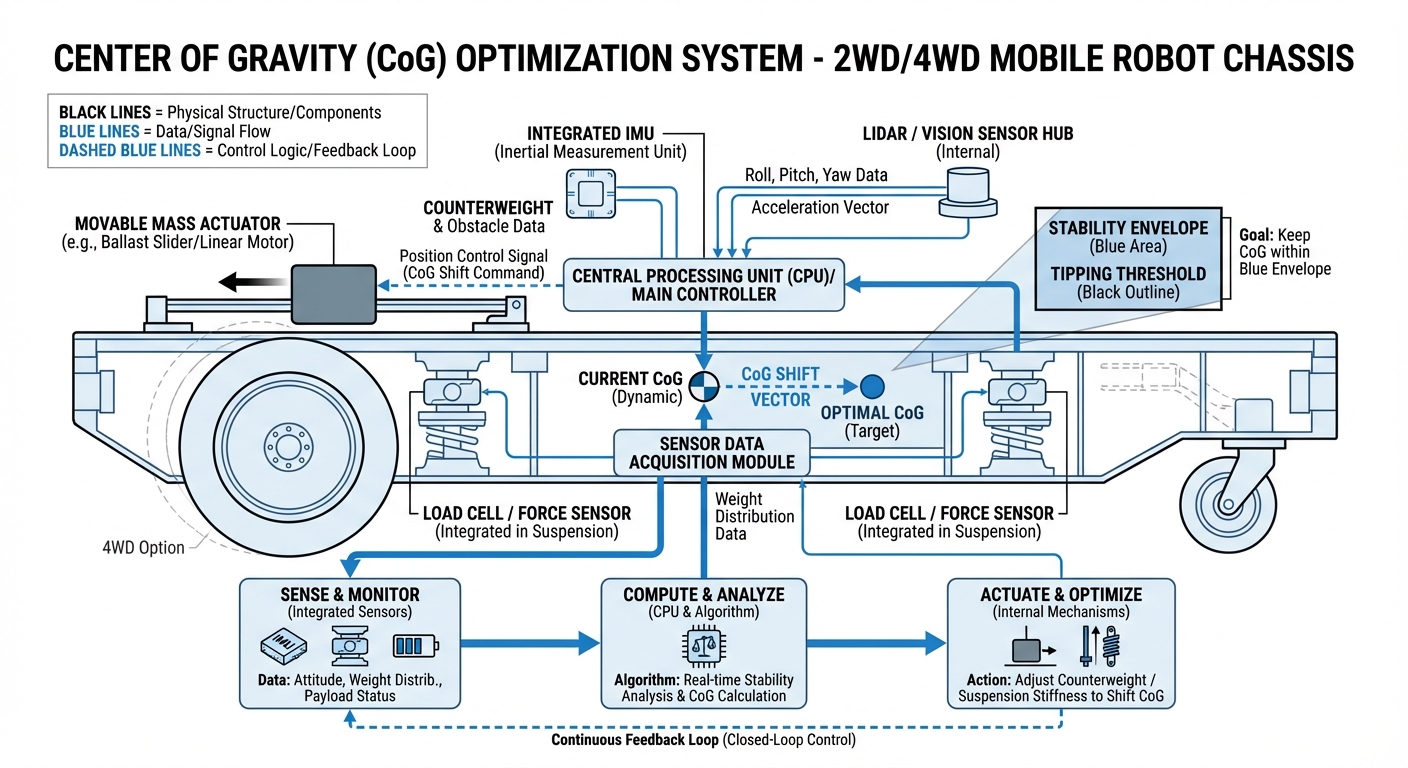

Active Balancing

For advanced robotics, this involves moving counterweights or adjusting suspension height dynamically to keep the CoG perfectly centered.

How It Works

Center of Gravity Optimization is not just about physical design; it is a continuous software process. Modern AGVs utilize Inertial Measurement Units (IMUs) to detect pitch, roll, and yaw in milliseconds.

When a robot lifts a load, the combined CoG of the vehicle and the payload shifts upward and often forward. The control software calculates the new "Zero Moment Point" (ZMP). If the ZMP approaches the edge of the wheelbase, the system automatically limits acceleration or reduces cornering speed to maintain contact with the ground.

This preemptive calculation allows robots to move faster when safe, and slow down only when necessary, maximizing throughput without compromising the safety of the facility or the inventory.

Real-World Applications

High-Reach Forklift AGVs

In high-bay warehousing, lifting heavy pallets to 10+ meters creates a high CoG. Optimization algorithms strictly limit travel speed based on current fork height to prevent lateral tipping.

Liquid Transport (Hospitals/Chemicals)

Transporting liquids introduces "sloshing," which creates a dynamic, oscillating CoG. Advanced motion profiles smooth out acceleration to dampen these forces and prevent spills.

Heavy Automotive Manufacturing

AMRs carrying car chassis or engine blocks deal with massive loads. CoG optimization ensures that emergency stops do not cause the load to slide or the robot to nose-dive.

Outdoor & Ramp Logistics

Robots transitioning from loading docks to trucks must handle steep inclines. CoG logic shifts traction control to prevent back-flipping or wheel slip on gradients.

Frequently Asked Questions

What happens if the Center of Gravity is too high?

A high CoG significantly reduces the stability margin. During cornering, the centrifugal force acts on a longer lever arm, increasing the likelihood of the robot tipping over. It also reduces traction on the inner wheels, potentially confusing navigation odometry.

Does CoG optimization require special sensors?

Yes, typically an IMU (Inertial Measurement Unit) is required to detect tilt and acceleration forces. Additionally, load cells or torque sensors in the lifting mechanism are used to estimate the mass and position of the payload being carried.

How does the robot know the weight of the payload?

Robots often use current sensing in the lift motors (more torque = heavier load) or dedicated load cells in the suspension or lift plate. Some advanced systems use visual estimation, but direct force measurement is the industry standard for accuracy.

Can software fix a poorly designed robot chassis?

Software can mitigate risks by limiting speed and acceleration, but it cannot fix physical physics limitations. A chassis with a very narrow wheelbase and high CoG will always be inherently unstable, forcing the software to run the robot very slowly to maintain safety.

How do ramps affect Center of Gravity calculations?

On a ramp, the gravity vector shifts relative to the robot's base. If climbing, the weight shifts to the rear wheels; if descending, to the front. The optimization algorithm must account for this grade to prevent back-flipping or loss of braking traction.

What is the "Support Polygon"?

The support polygon is the geometric shape formed by connecting the contact points of the wheels with the ground. For a robot to remain statically stable, the vertical projection of the CoG must fall inside this shape. If it exits the shape, the robot tips.

How does acceleration affect stability?

Acceleration creates an "inertial force" acting in the opposite direction of travel at the height of the CoG. This creates a rotational moment (torque) that tries to lift the front wheels. CoG optimization limits acceleration rates to keep this moment manageable.

Is this relevant for omnidirectional robots?

Absolutely. Omnidirectional robots (using Mecanum wheels, for example) can move sideways. This introduces new tipping axes. CoG optimization is arguably more complex here as the robot can tip in any direction, not just forward/backward or left/right.

What safety standards govern CoG and stability?

ISO 3691-4 is the primary standard for driverless industrial trucks. It mandates that the vehicle must maintain stability under all expected operating conditions, including emergency braking and load handling, necessitating rigorous CoG analysis.

Does battery placement impact CoG?

Yes, batteries are often the heaviest single component in an AGV. Designers intentionally place battery packs as low as possible (often forming the floor of the chassis) to act as a ballast, lowering the overall CoG and improving stability.

Can CoG shifts cause navigation errors?

Indirectly, yes. If weight shifts off the drive wheels due to a high CoG during acceleration, the wheels may slip. This wheel slip causes the encoder data to mismatch the actual distance traveled, leading to localization errors in the navigation stack.

What is "Dynamic Braking" in relation to CoG?

Dynamic braking in this context refers to modulating the braking force based on load height. If a fork is raised high, the robot must brake gently to avoid tipping forward. If the fork is low, the robot can brake aggressively to stop faster.