Carbon Fiber Composites

Revolutionize AGV fleet efficiency by minimizing chassis weight without compromising structural integrity. Carbon fiber composites deliver superior strength-to-weight ratios, significantly extending battery autonomy and enhancing the dynamic performance of mobile robots.

Core Concepts

Strength-to-Weight Ratio

Carbon fiber offers a specific strength up to 5 times greater than steel. For AGVs, this means the chassis consumes less energy to move itself, reserving power for payload transport.

Anisotropic Properties

Unlike metals, strength can be tailored directionally. Engineers can align fibers to resist specific load paths typical in robotic lifting or cornering forces.

Fatigue Resistance

Composites do not yield plastically like metals. They maintain structural integrity over millions of duty cycles, crucial for 24/7 warehouse automation operations.

Vibration Damping

The polymer matrix absorbs vibrations better than metal. This protects sensitive LIDAR sensors and compute modules from high-frequency noise during movement.

Corrosion Immunity

Carbon fiber composites do not rust. This makes them ideal for robots operating in humid environments, chemical plants, or applications requiring frequent washdowns.

Thermal Stability

Carbon fiber has a near-zero coefficient of thermal expansion. This ensures chassis dimensions remain precise regardless of temperature, vital for precision docking.

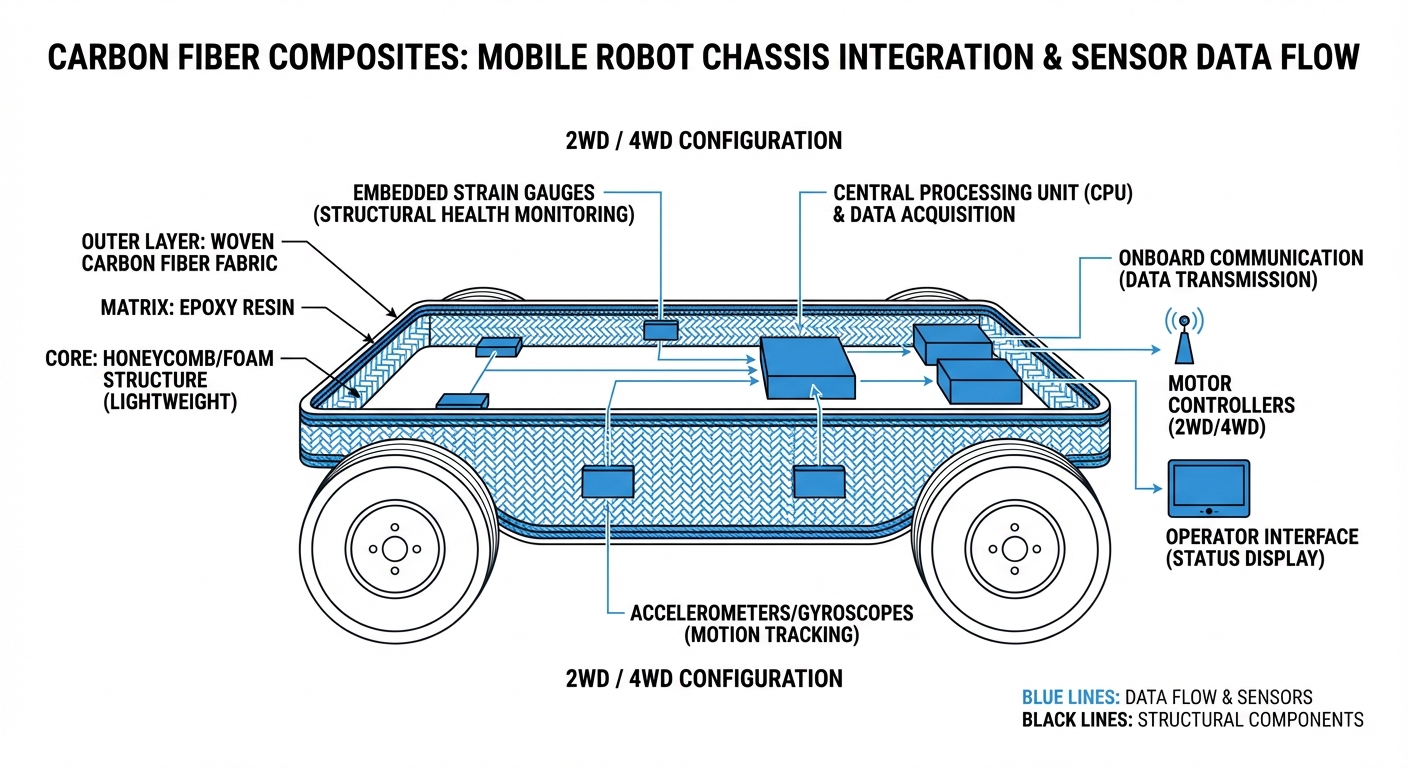

The Composite Architecture

Carbon fiber composites are materials created by combining two or more distinct substances: a reinforcement element (carbon fibers) and a binding matrix (usually polymer resin like epoxy). This combination produces material properties that are unavailable from the individual materials alone.

In the context of AGV manufacturing, the microscopic crystalline structure of the carbon fibers provides immense tensile strength. The resin matrix transfers the load between fibers and protects them from environmental damage.

By utilizing advanced lay-up techniques and autoclave curing, manufacturers can mold complex aerodynamic shapes that integrate structural components directly into the body, reducing part count and assembly time compared to traditional welded steel frames.

Real-World Applications

High-Speed Sorting Shuttles

In automated storage and retrieval systems (AS/RS), low inertia is critical. Carbon fiber shuttles can accelerate and brake faster, increasing throughput by up to 30% per hour compared to aluminum alternatives.

Heavy Payload AGVs

For robots designed to carry 1,000kg+ pallets, every kilogram saved on the chassis is an extra kilogram of payload capacity. Composites allow for slimmer designs that navigate tighter warehouse aisles.

Cleanroom & Medical Robotics

Composites are particulate-free and non-magnetic. They are essential in MRI environments or semiconductor manufacturing cleanrooms where metal dust or magnetic interference is unacceptable.

Collaborative Robot Arms (Cobots)

Mobile manipulators mounted on AGVs benefit from carbon fiber links. The reduced weight on the arm reduces the tipping moment, allowing for a smaller, more stable mobile base.

Frequently Asked Questions

How does the cost of carbon fiber compare to aluminum or steel for AGVs?

Carbon fiber is significantly more expensive upfront regarding raw material and mold tooling costs. However, the Return on Investment (ROI) is realized through operational efficiency: lower energy consumption, smaller required battery packs, and reduced motor wear, leading to a lower Total Cost of Ownership (TCO) over the robot's lifespan.

Is carbon fiber electrically conductive?

Yes, carbon fiber is electrically conductive, which can be a double-edged sword. While it can help with grounding, it requires careful insulation design to prevent short circuits with mounted electronics. Galvanic corrosion can also occur if aluminum parts are bolted directly to carbon fiber without a fiberglass or plastic barrier.

How repairable is a carbon fiber chassis if an AGV crashes?

Unlike steel which can be welded or bent back, carbon fiber damage is often structural and requires specialized patch repairs or component replacement. However, carbon fiber is incredibly resilient to impacts within its design limits and does not dent; it typically remains rigid until a catastrophic failure point.

Does carbon fiber block WiFi or RF signals?

Yes, carbon fiber composites attenuate radio frequencies significantly (Faraday cage effect). AGVs utilizing carbon fiber shells must have external antennas routed to the outside of the chassis or use "windows" made of fiberglass or Kevlar (which are RF transparent) for communication modules.

What is the typical weight saving percentage?

Switching from a steel chassis to a carbon fiber equivalent typically yields a 40% to 60% weight reduction. Compared to aluminum, the savings are usually around 20% to 30%, but with significantly higher stiffness and fatigue life.

How does it handle shock loading (e.g., dropping a pallet)?

Composites can be engineered for high impact resistance by using toughened resin systems or hybridizing with Kevlar layers. While metals absorb energy by deforming, composites absorb energy through micro-cracking or delamination, which must be inspected if a severe shock event occurs.

Is it suitable for outdoor mobile robots?

Absolutely. Carbon fiber is inherently resistant to corrosion and environmental degradation. However, the epoxy resin must be UV-stabilized or painted/coated to prevent degradation from long-term sun exposure.

What manufacturing method is best for AGV fleets?

For low-volume prototypes, hand lay-up or vacuum bagging is common. For larger fleets (100+ units), Resin Transfer Molding (RTM) or compression molding is preferred as it ensures high consistency, excellent surface finish, and faster cycle times.

Can we recycle carbon fiber AGV chassis at end-of-life?

Recycling is challenging but improving. Methods like pyrolysis (burning off the resin) allow the reclamation of the carbon fibers, which can be chopped and reused for non-structural injection molded parts. It is not as easily recyclable as melting down aluminum.

Does carbon fiber degrade over time with battery heat?

Standard epoxy resins have a Glass Transition Temperature (Tg) usually between 80°C and 150°C. As long as the battery packs and electronics operate within standard ranges, the chassis remains completely stable. For high-heat zones, specialized high-temp resins can be used.

Is it possible to embed sensors directly into the composite?

Yes, this is known as "smart composites." Fiber Bragg Grating (FBG) sensors or copper wiring can be embedded during the lay-up process to monitor structural health, temperature, or strain in real-time without external cabling.

How does it affect the robot's center of gravity (CoG)?

Because the upper body/chassis becomes significantly lighter, the Center of Gravity naturally lowers (assuming batteries/motors are bottom-mounted). This improves stability during high-speed cornering and reduces the risk of tipping for tall robots.