Buck and Boost Converters

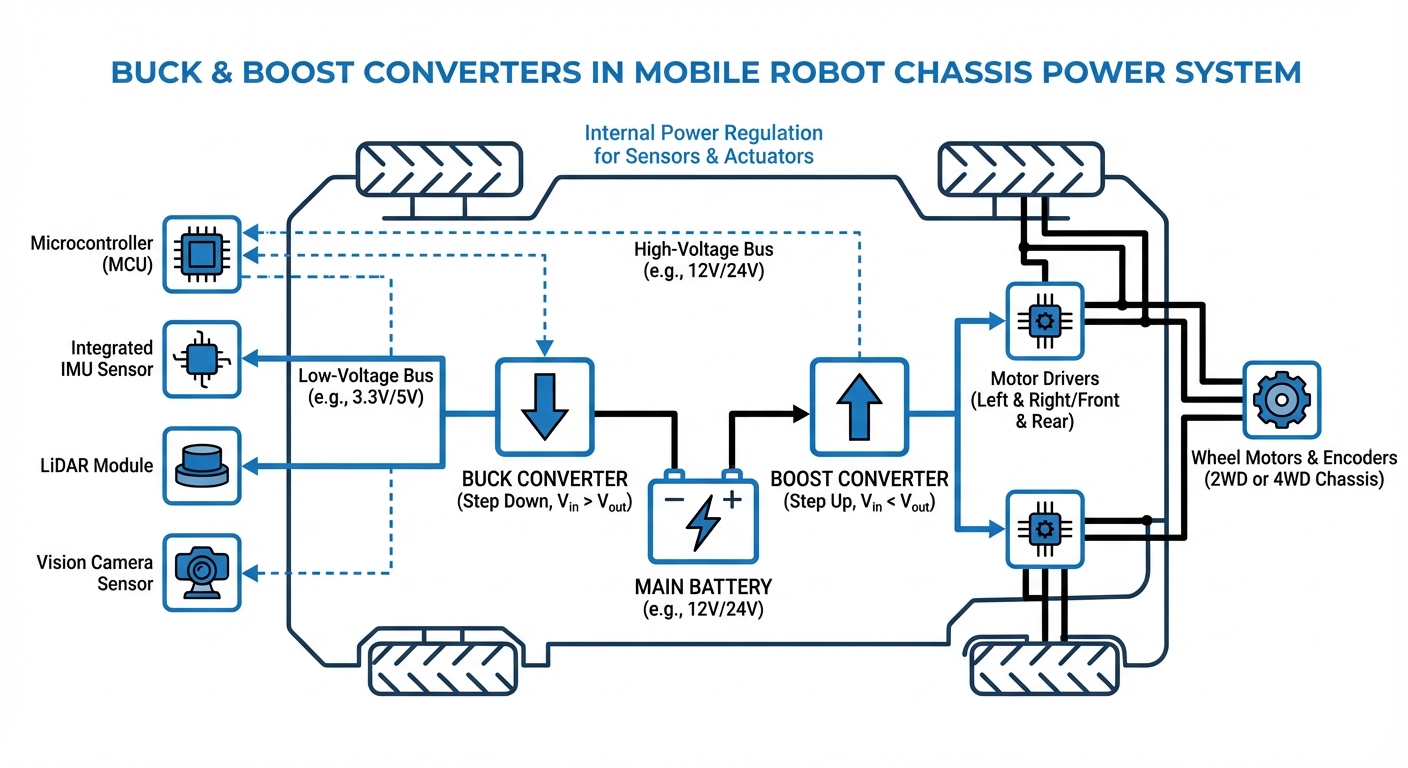

Master the power dynamics of your AGV fleet. Buck and boost converters are essential for stabilizing fluctuating battery voltages, ensuring your mobile robots' sensors, PLCs, and drive systems operate flawlessly under any load condition.

Core Concepts

Buck Conversion

Also known as step-down conversion. It efficiently lowers high battery voltage (e.g., 48V) to lower levels required by logic circuits (5V or 3.3V) with minimal heat loss compared to linear regulators.

Boost Conversion

The step-up process. It increases a lower input voltage to a higher output. Crucial when a battery dips below the operational threshold of specific components, such as 24V industrial sensors.

Power Efficiency

Unlike LDOs, switching converters often achieve 90-95% efficiency. In robotics, this directly translates to longer battery life and reduced thermal load inside the chassis.

Voltage Regulation

Maintaining a stable output voltage regardless of load current changes or input voltage fluctuations. This stability prevents sensitive LiDAR and navigation systems from rebooting.

Switching Noise

Converters operate by switching rapidly, creating "ripple." Advanced designs incorporate filtering to ensure this electromagnetic interference (EMI) doesn't disrupt wireless communication.

Thermal Management

High-current converters generate heat. Effective design includes heatsinks or thermal vias on the PCB to dissipate energy, preventing thermal shutdown during heavy AGV lifting operations.

How It Works: The Switching Cycle

At the heart of every switching converter (SMPS) is a high-frequency switch (usually a MOSFET) that turns on and off thousands of times per second. This process chops the input DC voltage into pulses.

Energy Storage: When the switch is closed, energy is built up in an inductor's magnetic field. When the switch opens, the inductor collapses its field, releasing stored energy to the load. A capacitor smooths out these pulses into a steady DC line.

Feedback Loop: A control circuit monitors the output voltage constantly. If the load increases (e.g., the AGV accelerates), the controller adjusts the "duty cycle" (the ratio of on-time to off-time) instantly to maintain a precise voltage level.

Real-World Applications

LiDAR & Navigation Power

LiDAR units typically require a strict 12V supply. As an AGV battery drains from 24V down to 18V, a Buck converter ensures the navigation sensors receive a clean, noise-free 12V, preventing localization errors.

Computing Units (IPC/PLC)

Industrial PCs are highly sensitive to voltage drops. A Buck-Boost converter is often used to maintain operational voltage even during high-current events (like motor startup) that cause temporary battery sag.

Motor Braking Energy

When an AGV brakes, motors act as generators. Boost converters can be used in regenerative braking systems to step up the back-EMF voltage to push energy back into the main battery pack, extending runtime.

Peripheral Integration

Warehousing robots often carry 5V USB peripherals (cameras, Wi-Fi dongles) and 24V actuators on the same 48V chassis. Multiple dedicated Buck converters allow these diverse components to coexist on a single power bus.

Frequently Asked Questions

What is the main difference between a Buck and a Boost converter?

A Buck converter acts as a step-down regulator, reducing input voltage to a lower output level (e.g., 24V to 12V). A Boost converter does the opposite, acting as a step-up regulator to increase input voltage to a higher output level (e.g., 12V to 24V). Both use switching technology to achieve high efficiency.

Why should I use a switching converter instead of a linear regulator (LDO) for AGVs?

Linear regulators dissipate excess voltage as heat, making them extremely inefficient for large voltage drops or high currents typical in robotics. Switching converters (Buck/Boost) typically offer 85-95% efficiency, conserving battery life and reducing the need for large heatsinks in the confined space of an AGV.

What is a Buck-Boost converter and when is it necessary?

A Buck-Boost converter can both step up and step down voltage. This is critical for battery-powered robots where the battery voltage starts higher than the required output (e.g., 14V) when fully charged, but drops below the required output (e.g., 10V) as it discharges, while the component needs a constant 12V.

How does ripple voltage affect AGV sensors?

High ripple voltage (noise on the power line) can introduce errors in analog sensors, cause jitter in servo motors, or disrupt LiDAR data packets. Quality converters for robotics include output capacitors and LC filters to minimize this ripple to acceptable levels (usually under 50mV).

How do I size a converter for my mobile robot?

Calculate the maximum continuous current and peak current (startup spikes) required by your load. Select a converter rated for at least 20-30% higher than your peak current requirement to ensure longevity and prevent thermal shutdown during intensive operations.

What are isolated vs. non-isolated converters?

Non-isolated converters share a common ground between input and output, which is simpler and cheaper. Isolated converters generally use a transformer to electrically separate the input from the output, which is safer for protecting sensitive logic boards from high-voltage motor spikes or ground loops.

Do switching converters cause electromagnetic interference (EMI)?

Yes, the rapid switching generates EMI which can affect wireless communications like Wi-Fi or LoRa. In AGVs, this is mitigated by using shielded cables, proper PCB layout with ground planes, and selecting converters with spread-spectrum frequency dithering.

What happens if the load current exceeds the converter's rating?

Most modern converters have built-in over-current protection (OCP). They will either "fold back" the voltage (drop the voltage to limit current) or enter a "hiccup mode" where they shut down and restart periodically until the fault is cleared, potentially causing the robot to reset.

Can I parallel multiple converters to get more current?

Generally, no. Unless the converters are specifically designed for "current sharing" or "multiphase operation," slight differences in output voltage will cause one converter to take the entire load, leading to failure. Always use a single converter rated for the total load if possible.

How does Quiescent Current (Iq) affect autonomous robots?

Quiescent current is the power the converter consumes when the system is in standby (no load). For AGVs that spend time idle or in sleep mode, a low Iq is essential to prevent the battery from draining unnecessarily over long periods of inactivity.

What are synchronous vs. non-synchronous converters?

Non-synchronous converters use a diode for the "freewheeling" path, which causes voltage drops and heat. Synchronous converters replace the diode with a second MOSFET, significantly improving efficiency, which is preferred for high-performance battery-operated robotics.