Brushed DC Motors

The foundational actuator for mobile robotics, offering high starting torque and simplified control logic. Discover why Brushed DC motors remain a vital, cost-effective solution for AGV drive systems and auxiliary mechanisms.

Core Concepts

Mechanical Commutation

Rotation is achieved via physical brushes contacting a commutator. This internal mechanical switching eliminates the need for complex external electronic controllers used in BLDC systems.

High Starting Torque

Brushed motors provide excellent torque at zero speed. This characteristic is crucial for heavy AGVs that need to overcome static friction to initiate movement from a dead stop.

Simplified Control

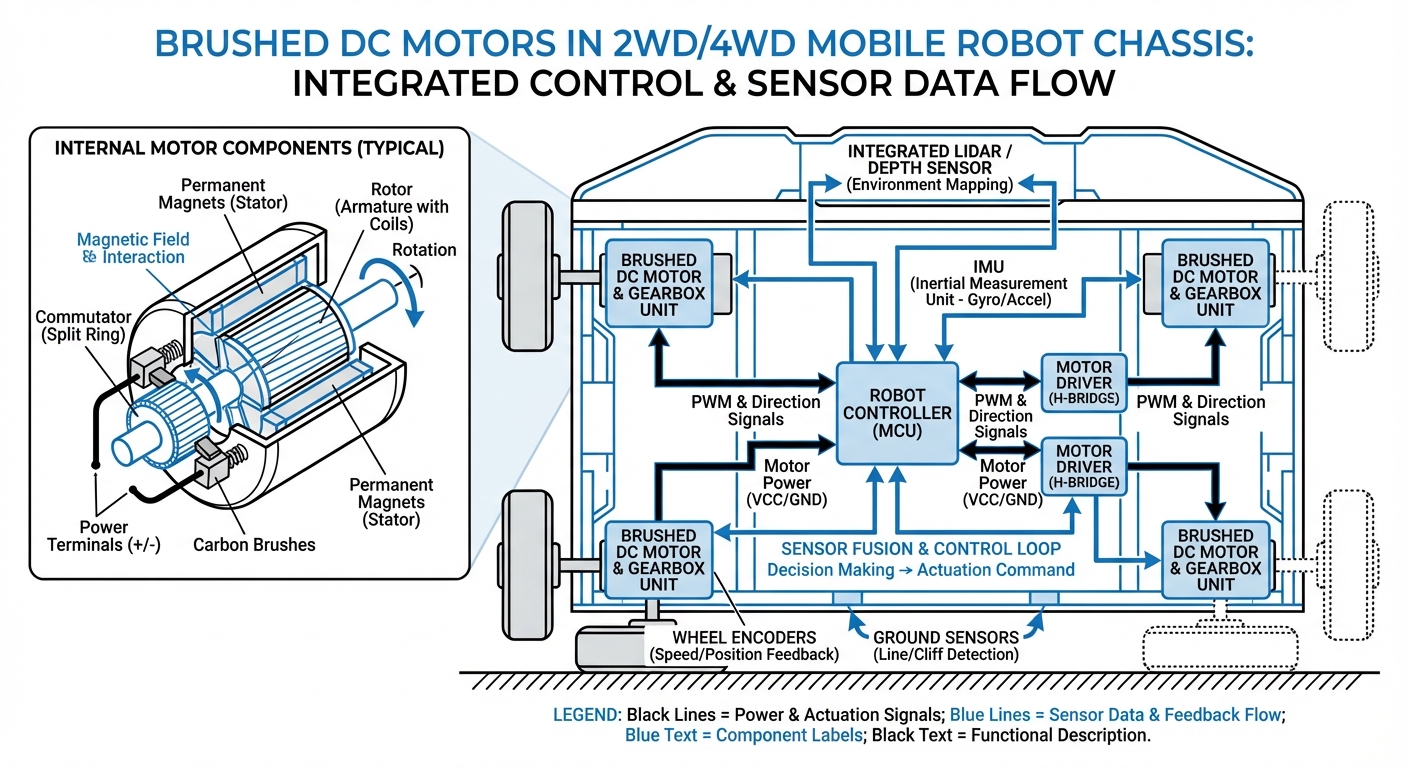

Speed is directly proportional to voltage, and torque is proportional to current. This linear relationship allows for straightforward implementation using basic H-Bridge drivers and PWM signals.

Two-Wire Interface

Requires only two power leads (positive and negative). Reversing polarity reverses direction. This reduces cabling complexity within the chassis of compact mobile robots.

Cost Effectiveness

Due to mature manufacturing processes and the lack of Hall effect sensors or complex drive electronics, brushed DC motors are significantly cheaper to deploy in budget-sensitive fleets.

Maintenance Factors

While powerful, the physical brushes wear down over time due to friction and arcing. Understanding the maintenance cycle is key to ensuring long-term fleet up-time.

How It Works

A Brushed DC motor consists of a stator (stationary part) providing a constant magnetic field and a rotor (rotating part) containing the armature windings. The key to its operation is the commutator-brush assembly.

As current flows through the brushes into the commutator segments, it energizes the armature coils. This creates an electromagnetic field that interacts with the stator's magnets, generating torque that turns the rotor.

Crucially, as the rotor spins, the commutator mechanically switches the direction of current flow in the windings at the precise moment required to keep the torque continuous. This "mechanical commutation" is what makes the motor spin without external phasing logic.

For AGVs, this translates to immediate responsiveness. When voltage is applied, the robot moves instantly, making these motors ideal for stop-and-go logistics operations.

Real-World Applications

Material Transport AGVs

Used in "tugger" style AGVs where high torque is needed to pull heavy carts, but precision positioning requirements are moderate. The lower cost allows for larger fleet deployments.

Warehouse Picking Robots

Small to medium-sized payload carriers utilize brushed motors for main drives due to the simplified PCB design, saving space inside the chassis for batteries and cargo.

Robotic Lift Mechanisms

Beyond propulsion, brushed motors are excellent for linear actuators that lift or clamp loads. Their ability to hold torque briefly simplifies the mechanics of lifting heavy pallets.

Inspection Crawlers

In rough terrain or pipe inspection robots, the rugged simplicity of a brushed motor creates a reliable drive system that is less susceptible to complex electronic failures in harsh environments.

Frequently Asked Questions

How does a Brushed DC motor compare to a Brushless (BLDC) motor for AGVs?

Brushed motors are simpler to control and cheaper upfront but require maintenance due to brush wear. BLDC motors offer higher efficiency, longevity, and power density but require complex electronic speed controllers (ESCs) and are more expensive. Choose brushed for cost-sensitive projects and BLDC for high-performance, 24/7 operations.

What is the typical lifespan of the brushes in a mobile robot application?

Lifespan varies heavily based on load and usage, typically ranging from 2,000 to 5,000 hours of operation. High current loads and frequent start-stop cycles accelerate wear. Many modern industrial brushed motors feature replaceable brushes to extend the total motor service life.

How do I control the speed of a brushed DC motor?

Speed is controlled using Pulse Width Modulation (PWM). By rapidly switching the voltage on and off, you change the average voltage reaching the motor. A higher duty cycle results in higher average voltage and faster speed, while a lower duty cycle slows it down.

Can I use regenerative braking with brushed motors?

Yes, when an AGV decelerates, the motor acts as a generator. With the correct H-Bridge driver design, this back EMF can be shunted back into the battery to recharge it (regenerative braking) or dissipated through a resistor (dynamic braking) to slow the robot down quickly.

What is "Back EMF" and why does it matter?

Back EMF is voltage generated by the spinning motor that opposes the driving voltage. It provides inherent self-regulation; as the motor speeds up, Back EMF increases, reducing current draw. It can also be measured to estimate motor speed without external sensors in simple applications.

Do brushed motors generate electrical noise?

Yes, the arcing at the brushes generates significant electromagnetic interference (EMI). Capacitors must be soldered across the terminals, and twisted-pair cabling should be used to prevent this noise from interfering with sensitive AGV sensors like LiDAR or microcontrollers.

Do I need an encoder for a brushed DC motor?

For basic movement, no. However, for an AGV to perform SLAM (Simultaneous Localization and Mapping) or precise odometry, an optical or magnetic encoder is required on the rear shaft to provide feedback on distance traveled and actual speed.

What maintenance is required for brushed motors in a warehouse setting?

Regular inspection of brush length is critical. Additionally, carbon dust from wearing brushes can accumulate inside the motor housing and should be blown out with compressed air periodically to prevent short circuits or reduced efficiency.

Why are geared brushed motors preferred for AGVs?

Standard DC motors spin very fast (thousands of RPM) with low torque. An attached gearbox reduces the speed to a usable walking pace for a robot while multiplying the torque significantly, allowing a small motor to move a heavy load.

How does voltage rating affect motor selection?

You should match the motor voltage (e.g., 12V, 24V, 48V) to your AGV's battery system. Higher voltage systems generally allow for lower current draw for the same power output, which results in thinner wiring and less heat generation in the driver electronics.

What happens if I stall a brushed DC motor?

Stalling occurs when the load is too heavy for the motor to turn. Current spikes to "Stall Current" levels, which is the maximum possible draw. If sustained for more than a few seconds, this will overheat the windings and burn out the motor or the driver.