Battery Cell Balancing

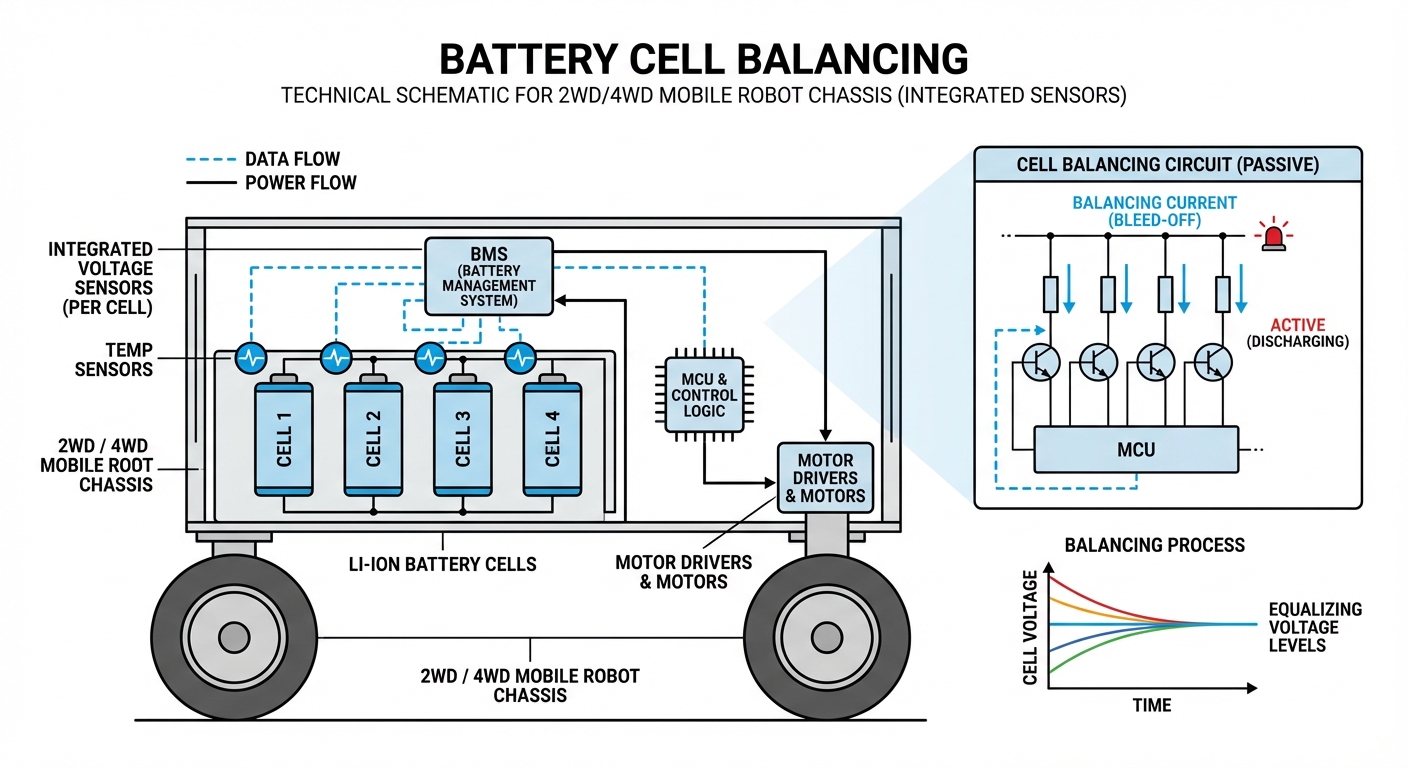

Maximize fleet uptime and extend battery lifespan by ensuring voltage uniformity across all cells in your power pack. In the world of 24/7 autonomous mobile robots, cell balancing is the critical safeguard against capacity degradation and unexpected downtime.

Core Concepts

State of Charge (SoC)

SoC refers to the level of charge of an electric battery relative to its capacity. Balancing ensures every individual cell reaches 100% SoC simultaneously.

Passive Balancing

The most common method in AGVs, where resistors bleed off energy from high-voltage cells to match lower cells. It is cost-effective and reliable for smaller packs.

Active Balancing

Uses capacitors or inductors to shuttle energy from high-voltage cells to low-voltage cells. It is highly efficient and minimizes heat generation in high-capacity packs.

Internal Resistance

As cells age, their internal resistance varies. Balancing compensates for these differences to prevent voltage drift during high-current discharges.

BMS Control

The Battery Management System (BMS) continuously monitors cell voltages. It triggers the balancing circuit when the difference between cells (delta) exceeds a threshold.

Pack Capacity

A battery pack is only as strong as its weakest link. Balancing ensures that the entire capacity of the pack is usable, rather than being limited by a single undercharged cell.

How It Works

In a typical AGV battery, cells are connected in series to achieve the required operating voltage (e.g., 24V or 48V). Over time, due to manufacturing tolerances and thermal gradients, individual cells charge and discharge at slightly different rates.

Without balancing, charging stops when the highest voltage cell hits the limit, leaving others undercharged. Conversely, the robot shuts down when the lowest cell hits the minimum cutoff, leaving stranded energy in other cells.

Cell balancing circuitry actively intervenes. During charging, it bypasses current around full cells (passive) or transfers energy (active), forcing all cells to reach their voltage target simultaneously. This synchronization maximizes the usable energy range for every robotic mission.

Real-World Applications

Warehouse Logistics AMRs

For fleets running 24/7, consistent battery performance is vital. Balancing prevents "phantom" low battery warnings, ensuring robots complete their picking routes without premature return-to-charger events.

Heavy Payload Forklifts

High-current draws during lifting create significant heat and voltage sag. Robust active balancing ensures that voltage recovery is uniform across the pack, preventing cutouts during heavy lifts.

Cold Storage Robotics

Low temperatures dramatically increase internal resistance variance in Lithium-ion cells. Aggressive balancing protocols are required to maintain pack integrity and prevent lithium plating in freezer environments.

Medical Service Robots

In hospital environments where reliability is non-negotiable, precise cell balancing ensures safety systems remain powered and battery health is accurately reported to fleet managers.

Frequently Asked Questions

What is the difference between Passive and Active balancing?

Passive balancing uses resistors to burn off excess energy from high-voltage cells as heat, allowing lower cells to catch up; it is simple and cheap but inefficient. Active balancing uses complex circuitry to transfer energy from high cells to low cells, preserving total energy and reducing heat, making it better for large, high-performance packs.

Why do battery cells become unbalanced?

Cells become unbalanced due to slight variations in manufacturing (capacity/impedance), uneven temperature distribution within the battery pack (thermal gradients), and different self-discharge rates over time. Even high-quality cells will drift apart after hundreds of charge cycles without balancing.

Does fast charging affect cell balance?

Yes, fast charging generates more heat and can exacerbate differences in internal resistance, leading to faster voltage drift. While modern BMS units can handle this, frequent fast charging necessitates more robust balancing capabilities to maintain pack health.

How often does the balancing process occur?

This depends on the BMS programming. Typically, "top balancing" occurs near the end of the charging cycle when cells are close to 100% SoC. Some advanced active BMS systems perform balancing continuously, even during discharge, to maximize runtime.

What are the signs of an unbalanced battery pack in an AGV?

Common signs include a sudden drop in range or runtime, the battery charging to "full" much faster than usual (premature cutoff), or the BMS reporting a fault code related to "Cell Delta" or "Cell Variance." The robot may also shut down unexpectedly under load.

Does cell balancing extend the total lifespan of the robot?

Absolutely. By preventing individual cells from being overcharged or over-discharged, balancing reduces chemical stress on the battery chemistry. This keeps the pack healthy for more cycles, delaying the expensive capital cost of battery replacement.

Can I replace a single bad cell in a balanced pack?

Generally, no. Mixing a new cell with aged cells creates a massive imbalance in capacity and resistance that the BMS cannot correct. It is industry standard to replace the entire module or pack to ensure safety and performance.

Is balancing more important for LiFePO4 (LFP) or NMC chemistries?

Balancing is critical for both, but LFP has a very flat voltage curve, making it harder for the BMS to detect imbalances until the very end of the charge. Therefore, precise and frequent balancing is exceptionally important for LFP packs used in robotics.

What happens if the balancing circuit fails?

If balancing fails, the voltage gap between cells will widen with every cycle. Eventually, the weakest cell will hit the low-voltage cutoff immediately upon load, effectively rendering the battery unusable despite other cells having charge, or causing safety lockouts.

How much balancing current is needed?

For small service robots, 50mA to 100mA is sufficient. However, for large industrial AGVs with high-capacity packs (e.g., 100Ah+), balancing currents of 1A to 5A may be required to correct imbalances within a reasonable charging timeframe.

Does temperature affect the balancing process?

Yes. Most BMS units will disable balancing if the battery is too cold (below freezing) or too hot to prevent damage. Passive balancing also generates heat, so the BMS monitors temperature to prevent overheating the circuitry during the process.

Is manual balancing ever required?

In severe cases where a pack has been left discharged for months, automatic balancing may be too slow. Technicians may need to manually charge individual parallel groups to bring them within range of the BMS, though this requires specialized equipment.