Ackermann Steering Geometry

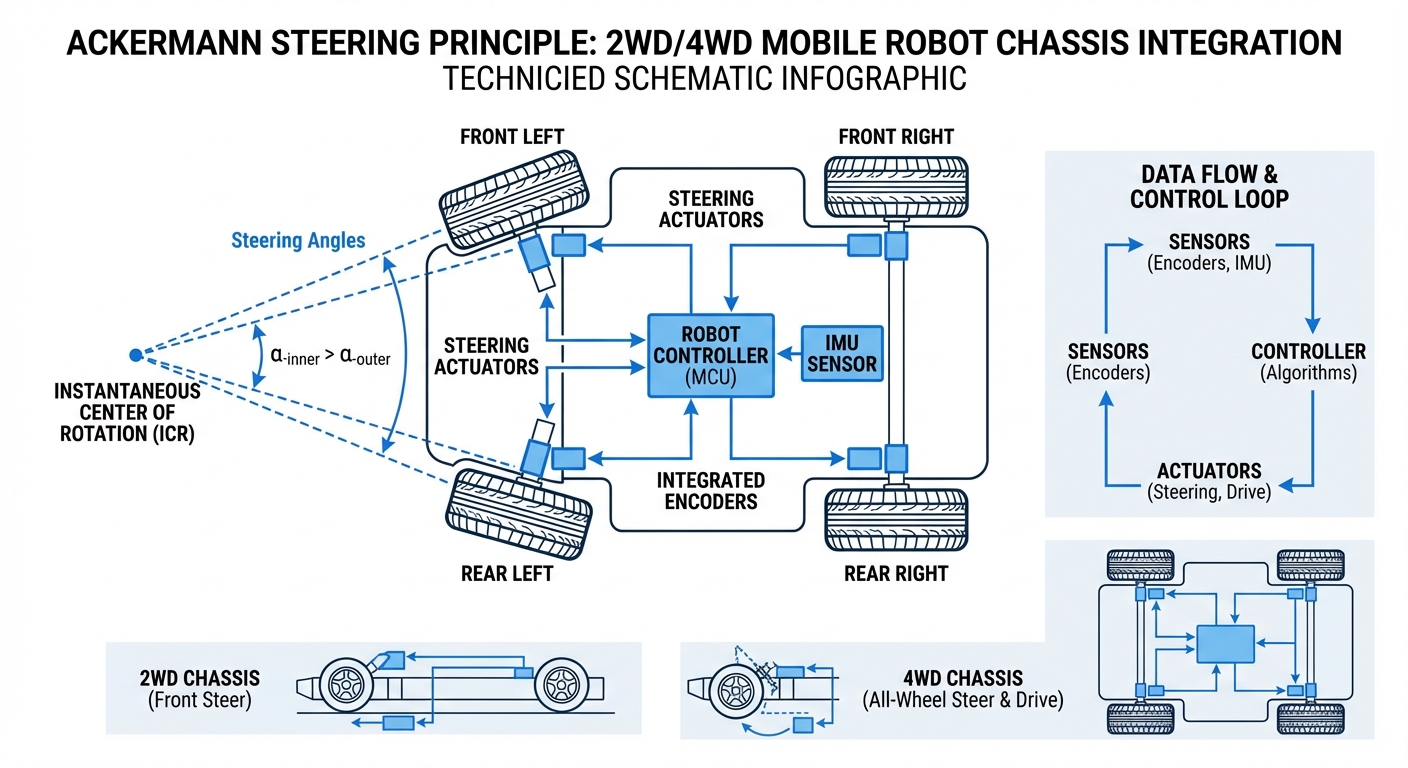

The fundamental kinematic standard for high-speed stability and tire longevity in autonomous mobile robots. Ackermann geometry ensures inner and outer wheels track unique radii to eliminate slip during turns.

Core Concepts

Geometric Center

The defining feature of Ackermann steering is that the projection of all wheel axles intersects at a single "Instantaneous Center of Rotation" (ICR), preventing wheel scrubbing.

Non-Holonomic Constraints

Unlike mecanum drives, Ackermann vehicles have kinematic constraints. They cannot move sideways directly, requiring path planning algorithms that account for turning radii.

High-Speed Stability

This geometry provides superior directional stability at higher velocities compared to differential drive robots, making it ideal for outdoor and long-distance transport.

Trapezoidal Linkage

Mechanically achieved via a steering trapezoid linkage, ensuring the inner wheel turns at a steeper angle than the outer wheel during a curve.

Tire Efficiency

By eliminating lateral slip, Ackermann steering significantly reduces tire wear and tear, lowering maintenance costs for fleet operators.

Electronic Differentials

Modern EV robotics often simulate Ackermann geometry via software ("Electronic Differential") using independent wheel motors rather than mechanical linkages.

How It Works

The core challenge in steering a four-wheeled vehicle is that the inner wheel travels a shorter distance than the outer wheel during a turn. If both wheels turned at the same angle (parallel steering), one or both would slip sideways, causing friction, tire wear, and inefficient power usage.

Ackermann steering solves this by arranging the steering linkages so that the inner wheel turns at a sharper angle ($\delta_i$) than the outer wheel ($\delta_o$). Mathematically, this satisfies the condition where the cotangent of the outer angle minus the cotangent of the inner angle equals the track width divided by the wheelbase.

In robotics, accurately modeling this kinematic constraint is crucial for odometry and path planning. The controller must calculate the specific angular velocity required for the rear wheels and the steering angle for the front wheels to execute a smooth arc without deviation.

Real-World Applications

Autonomous Tuggers

Used in manufacturing facilities to tow strings of carts. Ackermann geometry allows these heavy-duty robots to maintain consistent traction while hauling thousands of kilograms.

Last-Mile Delivery Bots

Outdoor delivery robots operating on sidewalks and roads rely on this steering for stability at cruising speeds and to navigate curb ramps without slipping.

Agricultural Robotics

Automated tractors and harvesters use Ackermann steering to navigate fields while minimizing soil disturbance and crop damage caused by skid-steering.

Hospital Logistics

Large linen and waste transport AGVs in hospital corridors utilize this steering to ensure quiet operation and floor protection compared to differential drive systems.

Frequently Asked Questions

What is the main difference between Ackermann and Differential Drive?

Differential drive relies on varying wheel speeds to turn and can rotate in place (zero radius turn), but suffers from stability issues at high speeds. Ackermann steering uses a mechanical or electronic steering angle for direction, offering superior stability and efficiency at speed, but has a limited minimum turning radius.

Does Ackermann steering allow for zero-radius turns?

No, strictly speaking, standard Ackermann steering does not allow for rotation in place. It requires a forward or backward motion to change heading, resulting in a minimum turning radius defined by the maximum steering angle and the vehicle's wheelbase.

How does Ackermann geometry impact robot odometry?

Odometry is generally more accurate over long distances with Ackermann steering because wheel slip is minimized. However, the mathematical model is non-linear ($x, y, \theta$), requiring more complex kinematic equations compared to the simpler differential drive model.

What is an "Electronic Differential" in this context?

Instead of a heavy mechanical differential gear, modern robots use independent motors for rear wheels. The software controller calculates the exact speed required for the inner and outer wheels based on the steering angle to simulate a perfect differential effect.

Is Ackermann steering suitable for narrow warehouse aisles?

Generally, no. Because it cannot turn in place, it requires wide turning aprons. For Very Narrow Aisle (VNA) applications, mecanum wheels, swerve drives, or differential drives are usually preferred due to their omnidirectional or zero-turn capabilities.

How do you path plan for an Ackermann robot?

Path planning requires algorithms that respect non-holonomic constraints, such as Hybrid A* or Reeds-Shepp curves. The planner must account for the vehicle's minimum turning radius and cannot simply vector the robot sideways to reach a goal.

What is the "Jeantaud" diagram?

The Jeantaud diagram is a graphical representation used to design the steering linkage. It helps engineers determine the correct angle of the steering arms relative to the axle to achieve the closest approximation of true Ackermann geometry.

Why is it preferred for outdoor robots?

Outdoor terrain is often uneven and abrasive. Ackermann steering maintains better ground contact and traction control. Skid-steering (differential) on high-friction surfaces like asphalt consumes immense power and rapidly destroys tires.

Does Ackermann geometry work in reverse?

Yes, the geometry holds true in reverse, but the control dynamics become unstable (like backing up a car). Autonomous control systems need robust feedback loops to prevent "jackknifing" or oscillation when reversing an Ackermann steered robot.

What happens if the geometry is slightly off?

This is known as "Ackermann Error." While perfect geometry is ideal, slight deviations are common and acceptable (modern cars use parallel steering at low angles). However, significant error leads to tire scrubbing, increased motor load, and reduced battery life.

Is Double Ackermann steering different?

Yes. Double Ackermann (or 4-Wheel Steering) involves steering both the front and rear axles. This significantly reduces the turning radius and allows for "crab walking" (moving diagonally), offering a middle ground between standard Ackermann and omnidirectional drive.

What sensors are required for control?

At a minimum, you need rotary encoders on the drive wheels for speed/distance and an absolute encoder or potentiometer on the steering column to know the current steering angle ($\phi$). IMUs are often added to correct for any wheel slip.