5G Low Latency Communication

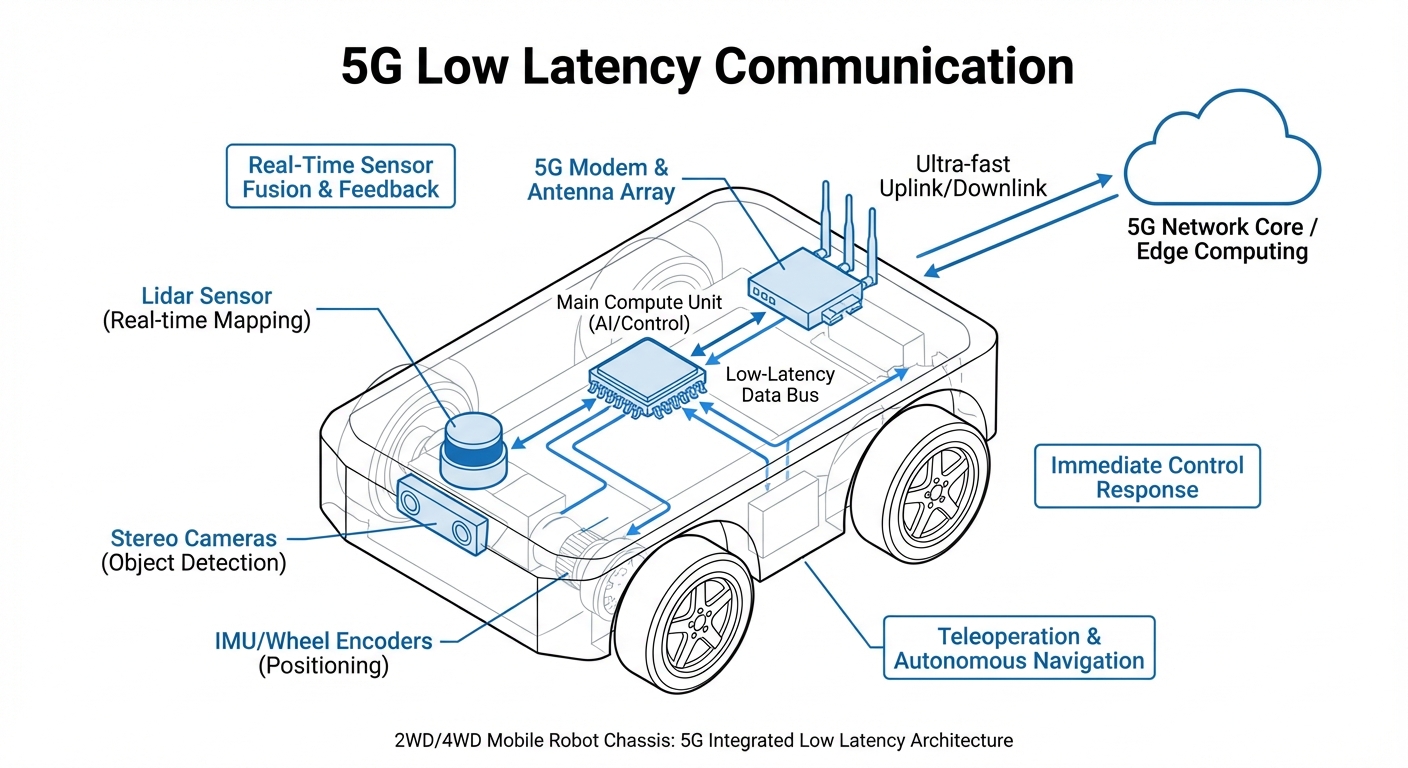

Unlock the potential of Ultra-Reliable Low Latency Communication (URLLC) to drive real-time decision-making in autonomous mobile robots. Experience near-instantaneous data transmission essential for safety-critical swarm coordination and cloud-based AI processing.

Core Concepts

URLLC Architecture

Ultra-Reliable Low Latency Communication is defined by 3GPP to ensure data delivery within milliseconds with 99.999% reliability, vital for safety protocols.

Network Slicing

Allows the creation of a virtual, dedicated network lane specifically for robotics traffic, isolating it from general bandwidth interference.

Mobile Edge Computing

Processes sensor data at the edge of the network (MEC) rather than the cloud, reducing round-trip time significantly for navigation logic.

Private 5G Networks

Deploying localized 5G infrastructure within a facility ensures total control over coverage, security, and quality of service (QoS).

Time-Sensitive Networking

Integrates 5G with TSN standards to provide deterministic synchronization, ensuring robots and conveyors operate in perfect unison.

Beamforming

Directs radio waves specifically toward the AGV rather than broadcasting in all directions, improving signal strength and reducing latency.

How Low Latency Transforms Navigation

Traditional Wi-Fi networks often suffer from "handover latency"—the time it takes for a robot to switch connection from one access point to another. In dynamic environments, this can cause navigation pauses or safety stops.

5G eliminates this bottleneck. With latency as low as 1-10ms, AGVs can offload heavy processing (like SLAM mapping or object recognition) to a local Edge Server. The robot sends raw sensor data, the server processes it instantly, and navigation commands are returned faster than the robot's physical reaction time.

This architecture reduces the need for expensive onboard computers, making the fleet lighter, more energy-efficient, and smarter through centralized AI updates.

Real-World Applications

Cloud-Based SLAM

Robots stream LiDAR data to a central server to construct dynamic maps in real-time, allowing fleet-wide map updates instantly without individual robot reprocessing.

Swarm Coordination

In high-density warehouses, hundreds of AMR shuttles communicate position and velocity data within milliseconds to weave through traffic without collision.

Haptic Teleoperation

Operators can control robots in hazardous environments remotely. 5G ensures the video feed and haptic feedback arrive with zero perceptible lag.

Real-Time Safety Interlocks

External safety sensors in the facility can trigger emergency stops on AGVs immediately upon detecting human intrusion, relying on 5G's 99.999% reliability.

Frequently Asked Questions

What distinguishes 5G URLLC from Wi-Fi 6 for robotics?

While Wi-Fi 6 offers high bandwidth, 5G URLLC is designed for deterministic reliability and seamless mobility. 5G handles "handover" between antennas much smoother than Wi-Fi roaming, preventing connection drops that cause AGVs to stall in large facilities.

What is the typical latency achieved in a private 5G setup?

In optimized private 5G networks using Edge Computing, end-to-end latency typically falls between 5ms to 10ms. This is significantly lower and more stable than Wi-Fi, which can spike unpredictable due to interference.

Do I need a "Private 5G" network or can I use public 5G?

For mission-critical industrial robotics, a Private 5G network is highly recommended. It keeps data on-premise for security, guarantees bandwidth availability, and allows you to tune the network specifically for uplink-heavy robot traffic.

How does 5G affect the battery life of AGVs?

Modern 5G IoT modules are increasingly power-efficient. Furthermore, by offloading heavy computational tasks (like mapping) to the edge via 5G, the robot's onboard computer works less, often resulting in a net energy saving.

What hardware is required on the robot side?

Robots need an industrial 5G modem or router compatible with the frequency bands of your network (often Sub-6GHz for coverage or mmWave for speed). Many modern AGV controllers allow direct integration of M.2 5G modules.

How does 5G handle indoor obstacles like metal racking?

Metal creates multipath propagation. 5G uses "Massive MIMO" and beamforming to turn these reflections into an advantage, strengthening the signal. However, a proper site survey and small-cell deployment are crucial for coverage in dense racking.

Is 5G secure enough for sensitive industrial data?

Yes, 5G architecture has stronger native security than Wi-Fi. It uses SIM-based authentication (physical or eSIM), stronger encryption, and network slicing to completely isolate robot traffic from guest or employee data streams.

Can we retrofit existing AGVs with 5G connectivity?

Absolutely. Legacy robots using Wi-Fi or Ethernet can be connected to a 5G-to-Ethernet bridge or gateway. This instantly gives them the mobility and range benefits of the 5G network without changing the robot's internal architecture.

What is the cost comparison between Industrial Wi-Fi and Private 5G?

Private 5G generally has a higher initial CapEx for core network hardware and spectrum licensing. However, OpEx can be lower due to fewer access points required (better range) and significantly reduced downtime/troubleshooting compared to complex Wi-Fi mesh setups.

What happens if the 5G signal is momentarily lost?

Robots are programmed with "heartbeat" failsafes. If the URLLC link is severed, the AGV should execute an immediate controlled stop or switch to a local fallback navigation mode until the connection is restored, ensuring human safety.

Does 5G support 'Upload-Heavy' traffic?

Unlike commercial networks designed for downloading video, Private 5G can be configured with a heavy uplink bias. This is essential for robots streaming multiple 4K video feeds or LiDAR point clouds back to the server.

What is Time-Sensitive Networking (TSN) over 5G?

TSN ensures data packets arrive at exact, predictable times. Over 5G, this allows wireless robots to synchronize perfectly with wired machinery, such as a mobile arm picking an item off a moving conveyor belt without physical cables.