3D Printing in Robotics

Revolutionize your fleet with additive manufacturing. From rapid prototyping to durable end-use parts, discover how 3D printing accelerates development and enables custom solutions for Autonomous Mobile Robots (AMRs) and AGVs.

Core Concepts

Rapid Prototyping

Drastically reduce the design-to-deployment cycle. Engineers can test AGV chassis iterations and sensor mounts in hours rather than weeks, accelerating the R&D phase.

Topology Optimization

Create lightweight yet structurally sound parts. By using generative design and honeycomb infills, robot weight is reduced, extending battery life without sacrificing durability.

Digital Inventory

Eliminate physical warehousing for spare parts. Maintain a digital library of components (gears, brackets, covers) and print replacements on-demand directly at the facility.

Custom End-Effectors

Adapt robots to specific tasks instantly. Print custom grippers, vacuum cups, or hooks tailored to the specific geometry of the items the AGV needs to transport.

Complex Geometries

Manufacture parts impossible to machine with CNC. Integrate internal cooling channels or consolidated assemblies into a single printed piece to reduce failure points.

High-Performance Materials

Utilize engineering-grade thermoplastics like Carbon Fiber Nylon, PEEK, or TPU. These materials offer the heat resistance, flexibility, or rigidity required for industrial robotics.

How It Works: The Workflow

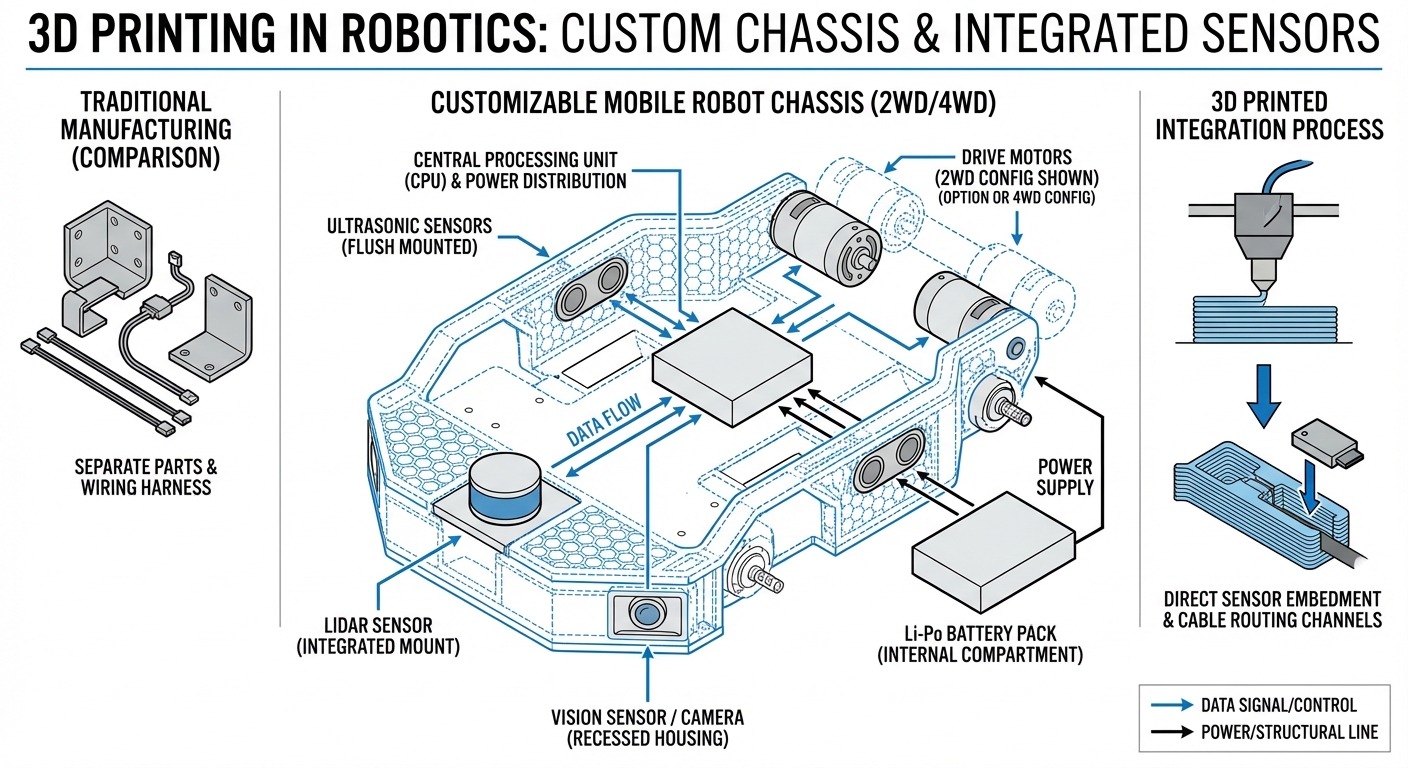

Integrating 3D printing into robotics operations moves beyond simple desktop prototyping. It involves a systematic workflow starting with CAD Design tailored for Additive Manufacturing (DfAM). Engineers optimize part orientation to handle the specific mechanical stresses the AGV will encounter during operation.

Once designed, the file is processed through slicing software where infill density and shell thickness are determined. For structural robot parts, high-strength composites like chopped carbon fiber are often used via Fused Deposition Modeling (FDM), while detailed sensor housings may use Stereolithography (SLA).

Post-processing is the final critical step. This ensures dimensional accuracy for fitting onto the robot chassis and may include annealing for thermal resistance or vapor smoothing for a professional, dust-resistant finish suitable for clean-room environments.

Real-World Applications

Custom LiDAR & Sensor Mounts

Every facility layout is unique, requiring different sensor angles. 3D printing allows for the creation of bespoke brackets that position LiDAR and cameras at the exact optimal angles for navigation, without needing expensive tooling changes.

Soft Grippers for Fragile Cargo

Using flexible materials like TPU (Thermoplastic Polyurethane), AGVs can be equipped with "soft" robotic grippers. These are essential in logistics for handling delicate items or irregular packaging that rigid metal grippers might crush.

Protective Bumpers & Skirts

Sacrificial parts are crucial for AGV longevity. 3D printed bumpers can absorb impact energy during minor collisions. These parts are cheap to print and easy to replace, protecting the expensive internal electronics and chassis.

Cable Management Clips

Internal wire routing in compact mobile robots is often a challenge. Custom-printed cable guides and strain relief clips ensure wiring harnesses stay secure, preventing electrical shorts caused by vibration during robot movement.

Frequently Asked Questions

Are 3D printed parts strong enough for structural AGV components?

Yes, when the correct materials and design principles are used. Engineering materials like Carbon Fiber reinforced Nylon or Polycarbonate offer high tensile strength and stiffness comparable to aluminum for many applications, making them suitable for chassis components and load-bearing brackets.

Which 3D printing technology is best for robotics?

FDM (Fused Deposition Modeling) is most common for functional parts due to material variety and durability. SLA (Stereolithography) is preferred for high-precision, small sensor housings. SLS (Selective Laser Sintering) is excellent for complex, durable parts without needing support structures.

Can we use 3D printed parts in ESD (Electrostatic Discharge) sensitive environments?

Absolutely. There are specialized filaments available (such as ESD-safe PETG or ABS) that are formulated to be static-dissipative. These are essential for printing end-effectors or trays that handle electronic components to prevent static shock damage.

How does 3D printing affect the maintenance cost of a robot fleet?

It generally lowers maintenance costs significantly. Instead of keeping a large inventory of expensive spare parts or waiting weeks for shipping, operators can print replacement parts on-site for a fraction of the cost, reducing machine downtime.

What is the typical lifespan of a 3D printed robot part?

This varies by material and environment. UV-resistant materials like ASA can last years outdoors. For high-wear internal gears, Nylon allows for long operational life. However, printed parts are often cheaper to replace, allowing for a proactive maintenance schedule.

Does 3D printing limit the size of the robot parts I can make?

While printers have build volume limits, large parts like full AGV bumpers are often printed in sections and bonded together chemically or mechanically. Industrial large-format printers are also becoming more accessible for printing unibody chassis sections.

Is post-processing required for printed robot parts?

Usually, yes. Support removal is the minimum requirement. For dynamic parts, sanding may be needed to reduce friction. Threaded inserts are often heat-set into the plastic to provide durable metal threads for bolting components together.

How does weight reduction via 3D printing impact AGV performance?

Reducing the weight of the chassis and non-payload components directly improves the power-to-weight ratio. This results in longer battery runtime, increased payload capacity, and reduced wear on motors and wheels.

Can 3D printed parts handle high temperatures?

Standard PLA deforms at low temperatures (60°C), but engineering materials like Polycarbonate, PEEK, or PEI (Ultem) can withstand much higher temperatures (100°C - 200°C+), making them suitable for mounting near motors or heat sinks.

Is it cost-effective for mass production of robots?

For low to mid-volume production (hundreds of units), 3D printing is often more cost-effective than investing in injection molding molds. For high volume (thousands), traditional molding becomes cheaper, though printing remains superior for customization.

What software is needed to design for 3D printed robotics?

Standard CAD software like SolidWorks, Fusion 360, or Onshape is used for design. However, utilizing "Slicer" software features (like variable infill) and Generative Design modules helps maximize the benefits of additive manufacturing.

Are there food-safe options for restaurant service robots?

Yes, specific filaments (like certified PETG) are food-safe. However, the layer lines inherent in printing can harbor bacteria. Post-processing with a food-safe epoxy coating is recommended to seal the surface for service robots.