2D LiDAR

The essential "eye" of modern navigation, 2D LiDAR provides precise, single-plane laser scanning to enable SLAM, obstacle avoidance, and safety certification for Autonomous Guided Vehicles (AGVs) and mobile robots.

Core Concepts

Time of Flight (ToF)

Calculates distance by measuring the precise time it takes for a laser pulse to travel to an object and bounce back to the sensor.

Angular Resolution

Determines the density of data points. A finer resolution (e.g., 0.1°) detects smaller objects and thin legs of shelving units effectively.

Scan Rate (Hz)

The speed at which the sensor completes a full 360° rotation. Higher Hz (e.g., 25Hz) is critical for fast-moving AGVs to update positions in real-time.

Reflectivity Intensity

Beyond distance, modern LiDARs measure return signal strength, helping robots distinguish between retro-reflective tape, matte walls, and metal.

Safety Zones

Configurable virtual perimeters (Warning vs. Protective fields) that trigger speed reduction or emergency stops (e-stop) when breached.

SLAM Ready

Simultaneous Localization and Mapping utilizes the point cloud data to construct maps of unknown environments while tracking the robot's location.

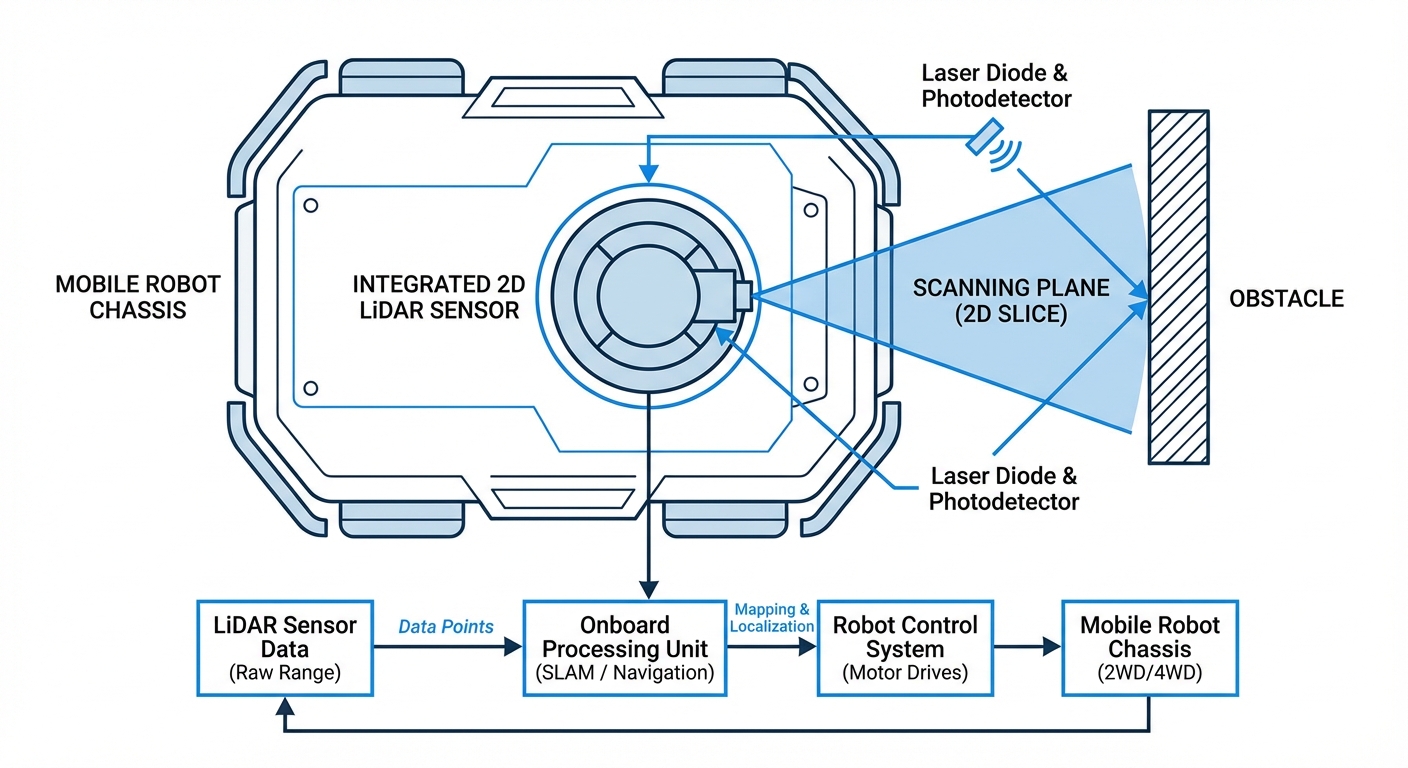

How It Works

2D LiDAR operates on the principle of high-speed laser telemetry. A laser emitter sends pulses of light toward a rotating mirror. This mirror deflects the beam outward into the environment across a single horizontal plane (2D).

When the light hits an object—such as a wall, pallet, or human—it reflects back to the sensor. The sensor calculates the distance based on the Time of Flight (ToF) or phase shift. This happens thousands of times per second.

The result is a polar coordinate map (distance and angle) known as a "Point Cloud." This raw data is fed into the robot's navigation stack (usually via ROS) to calculate geometry, identify obstacles, and update the global costmap for path planning.

Real-World Applications

Warehouse Logistics (AMRs)

Autonomous Mobile Robots use 2D LiDAR to navigate dynamic warehouse aisles, dodging forklifts and workers while transporting pallets without magnetic tape.

Industrial Safety Curtains

Fixed-position 2D LiDAR scanners monitor hazardous zones around robotic arms, automatically halting machinery if a human enters the defined perimeter.

Hospital Delivery Robots

Service robots utilize high-resolution LiDAR to navigate corridors, detecting thin objects like IV stands and ensuring smooth operation in crowded elevators.

Outdoor Patrol Bots

Robust 2D LiDAR units with multi-echo technology filter out rain and fog, allowing security robots to patrol perimeters effectively in variable weather.

Frequently Asked Questions

What is the difference between 2D and 3D LiDAR for robots?

2D LiDAR scans a single horizontal plane, making it cost-effective and computationally light, ideal for indoor floor mapping and safety. 3D LiDAR scans volume (height, width, depth), providing a complete environmental model but requires significantly more processing power and is generally more expensive.

Can 2D LiDAR detect glass or transparent surfaces?

Standard lasers often pass through clear glass or reflect off it unpredictably (specular reflection), causing "invisible" obstacles. Advanced navigation stacks fuse LiDAR data with ultrasonic or camera sensors to handle transparent surfaces, or require the application of opaque tape at the scan height.

How does sunlight affect 2D LiDAR performance?

Strong ambient light, like direct sunlight, can saturate the sensor's receiver, blinding it. For outdoor applications or areas with large windows, it is crucial to select LiDAR rated for high ambient light immunity (often measured in Lux, typically >40,000 Lux for outdoor use).

What is the typical range needed for an indoor AGV?

For typical warehouse environments, a detection range of 10 to 25 meters is standard. This allows the robot enough distance to detect obstacles at speed and decelerate smoothly. Longer ranges (30m+) are beneficial for localization in very large, open halls.

Why is "Angular Resolution" important for navigation?

Angular resolution determines the gap between laser points at a distance. A lower number (e.g., 0.1°) means higher density. This is critical for detecting small or thin objects (like table legs) at a distance, ensuring the robot doesn't mistake a thin obstacle for empty space.

What is the difference between Navigation LiDAR and Safety LiDAR?

Safety LiDARs are certified components (SIL 2/PL d) with redundant internal architecture designed to reliably trigger emergency stops to prevent human injury. Navigation LiDARs prioritize data density and range for mapping but are not rated to be the sole device responsible for human safety.

How often does the device need maintenance?

2D LiDARs are relatively low maintenance. The primary requirement is keeping the optical window clean from dust, oil, and fingerprints. Mechanical LiDARs have moving motors that may wear out after 20,000-50,000 hours, whereas solid-state options have longer lifespans.

What is "Crosstalk" or interference between robots?

When multiple robots operate in the same area, one robot's laser emitter can blind another robot's receiver. Modern LiDARs use multi-echo technology or specific encoding/frequency modulation to filter out signals that did not originate from their own emitter.

Can 2D LiDAR be used for SLAM (Simultaneous Localization and Mapping)?

Yes, 2D LiDAR is the primary sensor for 2D SLAM (like Gmapping or Cartographer). It builds a floor-plan style map. However, it cannot localize based on ceiling features or floor textures, which is why it is often fused with wheel odometry and IMUs.

Does the color of the object matter?

Yes. Dark black objects (low remission) absorb light, reducing detection range, while highly reflective objects (mirrors, polished metal) scatter light. High-quality LiDARs specify their range based on 10% reflectivity (black) to ensure reliable performance on all surfaces.

Is ROS (Robot Operating System) support standard?

Almost all industrial and research-grade 2D LiDAR manufacturers provide open-source ROS and ROS2 drivers. This allows for plug-and-play integration into the navigation stack, publishing `LaserScan` messages immediately upon connection.

What happens if the scanning plane is blocked?

Since 2D LiDAR scans a single line, an obstacle below or above that line (like a hanging forklift tyne or a low obstacle) will be missed. To mitigate this, robots often use 3D depth cameras or bumper sensors in conjunction with the main LiDAR.