Disinfection & Sanitization

Deploy autonomous mobile robots equipped with UV-C lights or dry-mist sprayers to eliminate 99.9% of pathogens. Ensure consistent, documented hygiene standards in high-traffic environments while protecting human staff from exposure to harmful chemicals and radiation.

Why Automate Disinfection & Sanitization?

Enhanced Safety

Reduce human exposure to harsh cleaning chemicals and dangerous UV-C radiation by offloading hazardous tasks.

Consistent Coverage

Robots follow precise programmed paths, ensuring no spot is missed and disinfection dwell times are strictly adhered to.

Verifiable Reports

Generate digital audit trails proving exactly when and where sanitization occurred for compliance and liability.

Cost Efficiency

Lower long-term labor costs and reduce chemical waste through precision dosing and automated workflows.

Scalable Deployment

Easily update maps and schedules across a fleet of robots to adapt to changing facility layouts or health protocols.

Pathogen Control

Effective against SARS-CoV-2, influenza, MRSA, and other healthcare-acquired infections (HAIs).

Autonomous Precision Cleaning

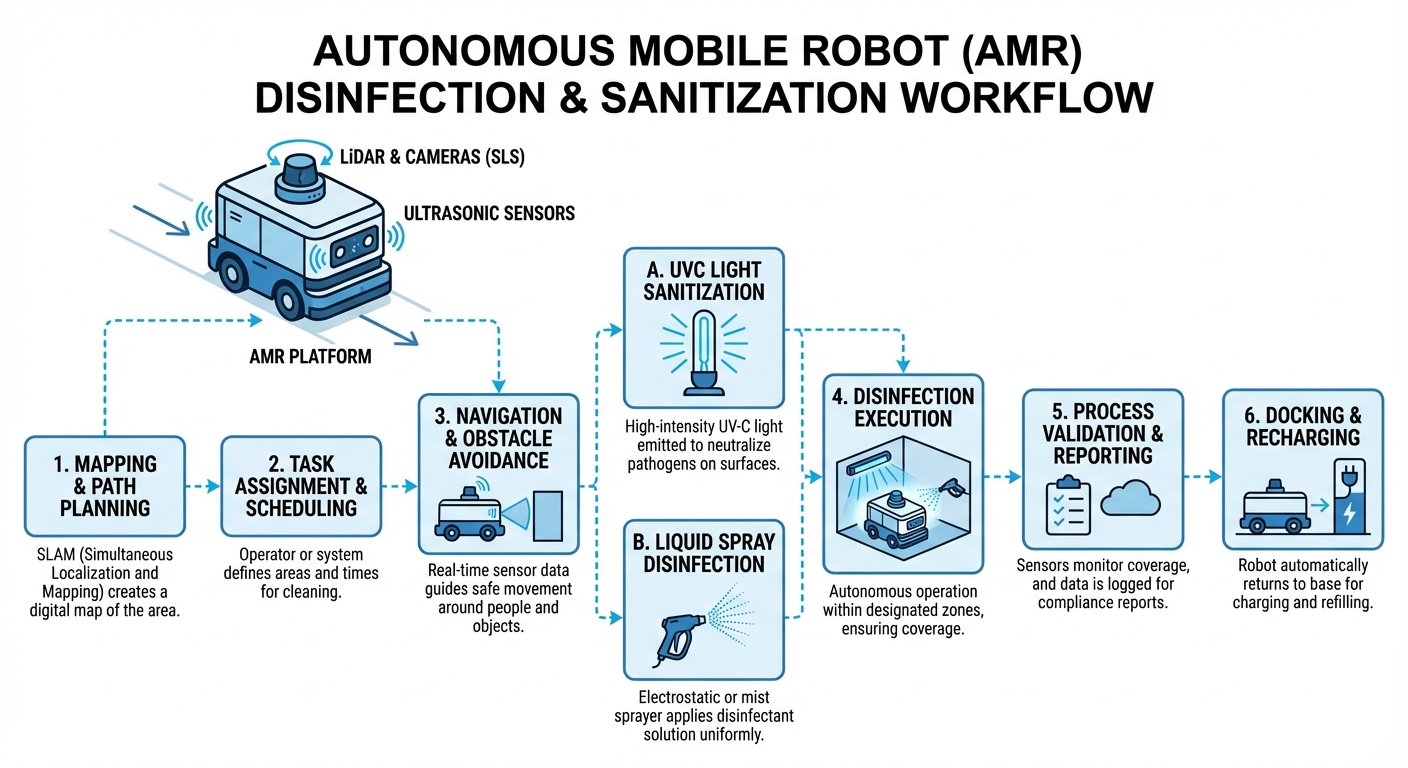

Disinfection robots operate by first creating a digital twin of your facility using SLAM (Simultaneous Localization and Mapping) technology. Operators define "disinfection zones" and "no-go zones" on this map.

Once deployed, the robot autonomously navigates the space. If equipped with UV-C, it calculates the necessary exposure time for specific surfaces to neutralize DNA/RNA of pathogens. If utilizing dry-mist, it dispenses a calculated cloud of disinfectant that settles on surfaces without damaging electronics.

Advanced sensors (LIDAR and Depth Cameras) ensure the robot detects obstacles and people instantly. If a human enters a UV-C robot's workspace, safety interlocks immediately shut off the lamps to prevent injury.