Airport Baggage Handling

Revolutionize terminal logistics with autonomous mobile robots designed for high-speed, accurate baggage sorting and transport. Eliminate bottlenecks and enhance ground handling safety with intelligent fleet coordination.

Why Automate Airport Baggage Handling?

Increased Throughput

Manage higher passenger volumes with robots capable of operating at consistent speeds without shift changes or fatigue.

Traceability & Accuracy

Reduce lost luggage (mishandled bags) by 99% with real-time tracking integration for every single robot movement.

Workplace Safety

Drastically reduce physical strain injuries among ground crew by automating the heavy lifting and transport across the tarmac.

Faster Turnaround

Optimized routing algorithms ensure baggage reaches the aircraft or carousel in the shortest time possible.

Flexible Scalability

Easily scale your fleet up during holiday peak seasons and scale down during off-peak times without infrastructure changes.

Operational Savings

Lower operational costs through reduced labor requirements, less equipment damage, and higher energy efficiency.

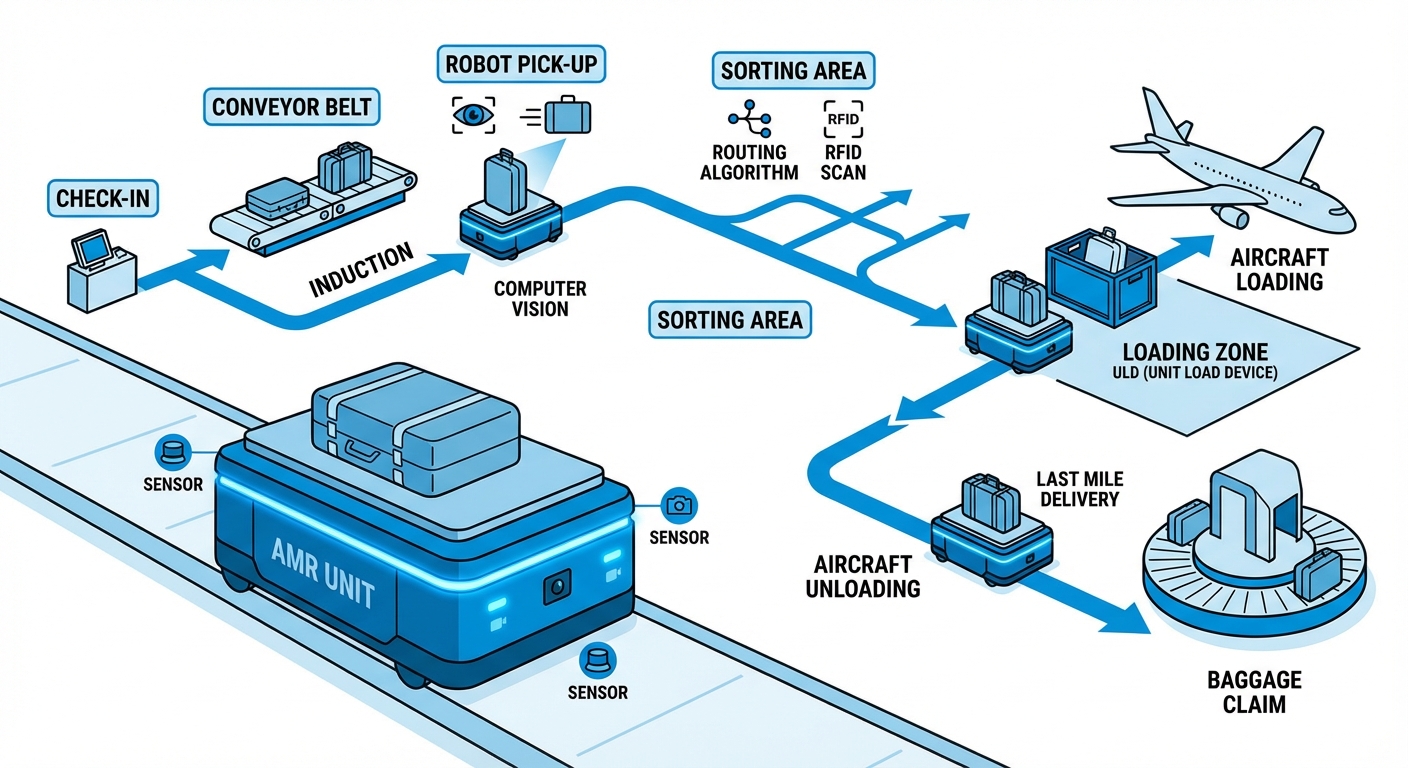

Seamless Integration Logic

Our Baggage Handling Robots (BHR) integrate directly with the airport's Baggage Handling System (BHS) software. When a bag is checked in, a robot is dispatched to the induction point. The robot scans the bag tag, verifying the flight data against the central database.

Using advanced LiDAR and SLAM (Simultaneous Localization and Mapping), the robot navigates the dynamic environment of the sorting hall or tarmac. It avoids obstacles, including personnel and other vehicles, ensuring total safety in shared workspaces.

The system optimizes the path to the specific flight loading container (ULD) or carousel. Once delivered, the robot automatically returns to the charging station or queues for the next assignment, creating a continuous, efficient loop.

Where It's Used

International Hubs

Managing complex inter-terminal transfers where bags must travel long distances between connecting flights with tight windows.

Regional Airports

Replacing fixed conveyor infrastructure with flexible mobile robots to accommodate fluctuating seasonal flight schedules.

Curbside Check-in

Autonomous collection robots operating at curbside or parking garages to transport luggage directly to security screening.

Oversized Baggage

Specialized heavy-load robots handling skis, golf clubs, and musical instruments that jam standard conveyor belts.

What You Need

| Component | Specification |

|---|---|

| Robot Payload | Minimum 50kg (standard) / 100kg (oversized) |

| Navigation Sensors | 3D LiDAR, RGB-D Cameras, IMU, Wheel Encoders |

| Connectivity | Private 5G or Enterprise Wi-Fi 6 (Low latency required) |

| Software Integration | API access to Airport Operational Database (AODB) & BHS |

| Environment | Flat concrete/epoxy flooring; ramps < 5 degrees inclination |

| Power Infrastructure | Automated Opportunity Charging Stations (220V/3-phase) |