Rocker-Bogie Suspension

The ultimate suspension for rock-steady autonomous mobile robots. Engineered for constant wheel-ground contact over brutal terrain, without jiggling payloads or throwing off sensors.

Core Concepts

Differential Mechanism

It links left and right sides via a differential pivot. One side lifts? The other presses down harder, keeping wheel pressure even across the board.

Spring-Less Design

Unlike car suspensions with springs, this uses rigid links and pure geometry—no bounce, just stable sensors.

Obstacle Climbing

It tackles obstacles up to twice the wheel diameter, all six wheels staying planted on the ground.

Body Stability

The chassis pitch averages between sides, so the body leans way less than the terrain itself.

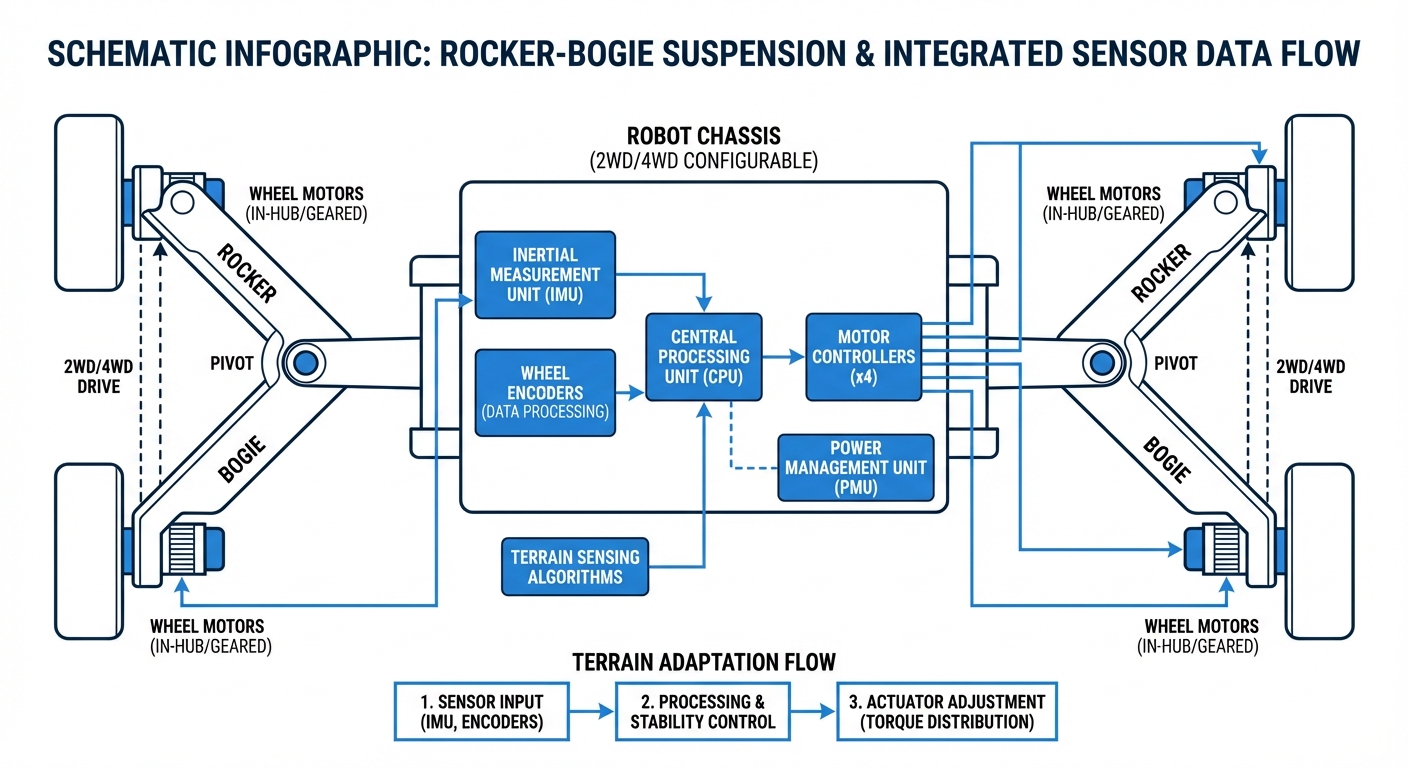

Independent Drive

Usually packs individual motors for all six wheels—top-tier traction and backup if one motor flakes out.

Static Stability

Tailored for low-speed, high-torque jobs where a steady center of gravity trumps zippy turns.

How It Works

'Rocker-Bogie' names the two core linkages per side. The bigger 'Rocker' pivots straight to the robot body; the smaller 'Bogie' attaches to the Rockers front.

The secret sauce? No rigid axles tying left and right wheels. A differential bar or gear joins the rocker pivots instead, letting bogies flex independently while averaging the overall angle.

For real-world AGVs, that means a 10cm curb under one wheel lifts the body just ~5cm—keeping LiDAR and visual SLAM cameras perfectly level.

Real-World Applications

Last-Mile Delivery

Delivery robots hustling over sidewalks, curb ramps, cracked pavement, or snow—without dumping groceries or parcels.

Industrial Inspection

Robots in oil & gas plants or construction sites, dodging debris, cables, and bumpy metal grates.

Search and Rescue

Compact AGVs crawling rubble and wreckage to find survivors, where suspension glitches aren't an option.

Agriculture

Crop-monitoring robots threading rows with shifting soil and irrigation ditches throwing constant curveballs.

Frequently Asked Questions

What is the primary advantage of Rocker-Bogie over independent suspension?

Load sharing without springs—that's the killer edge. Independent setups bounce the body, messing with nav sensors. Rocker-Bogie keeps all wheels grounded with even pressure for reliable grip on rough stuff.

Does this suspension support high-speed movement?

Generally no. It's dialed for low-speed stability (under 10-15 mph) and big torque. High speeds bring harsh vibes and chassis stress from zero shock absorption.

Why are six wheels standard for this configuration?

Six wheels nail the sweet spot of simplicity and rock-solid stability. Hit a step (one pair lifts), and four stay down for traction. Four-wheel versions exist but climb less.

How tall of an obstacle can a Rocker-Bogie robot climb?

A well-designed system can handle obstacles up to 1.5 to 2 times the diameter of its wheels. That's way better than standard car suspensions, which usually hit their limit at obstacles bigger than half the wheel diameter.

Does it require special motors or actuators?

You'll typically want a motor for each wheel (six in total) to get maximum traction. The suspension itself is passive and doesn't need special actuators, but those wheel motors need high-torque gearing to really take advantage of the climbing ability.

How does the differential mechanism work?

The differential keeps the robot body from spinning freely around the drive axles. It links the left and right rockers so that when one side lifts up, the other gets pushed down, holding the main chassis at an even pitch angle averaging the two sides.

Is Rocker-Bogie suitable for indoor warehouse AGVs?

It's probably overkill for smooth, flat concrete floors. But in older warehouses with cracked surfaces, cable protectors, or door thresholds, it offers much better protection for fragile payloads than basic rigid casters.

How is steering handled in this system?

Most setups go with 'Skid Steering' (like a tank), by varying the speed between left and right wheels to turn. Fancier versions, like NASA rovers, add dedicated steering servos on the corner wheels to cut down on tire wear and ground disturbance.

What are the maintenance requirements?

Maintenance is usually lower than with spring-shock systems since there are fewer parts that wear out from compression. Just keep an eye on the pivot bearings and differential linkage—make sure they're free of debris.

Does the payload weight affect the suspension performance?

Yes, big time. Without springs to cushion the load, the structural links have to handle the full static weight rigidly. Overload it, and you could bend the rocker arms or wreck the pivots—unlike a spring setup that just bottoms out harmlessly.

Is it expensive to implement?

It's pricier than a basic 4-wheel skid-steer because of the complex linkages, bearings, and the need for six motors plus controllers. But you save on sensor-heavy stabilization software, which balances things out.